Understanding AM Parts Design Will Lead to Mass Adoption of AM Technologies

Adoption of additive manufacturing technologies will pick up rapidly as companies begin to understand how to design parts according to the capability of additive machines.

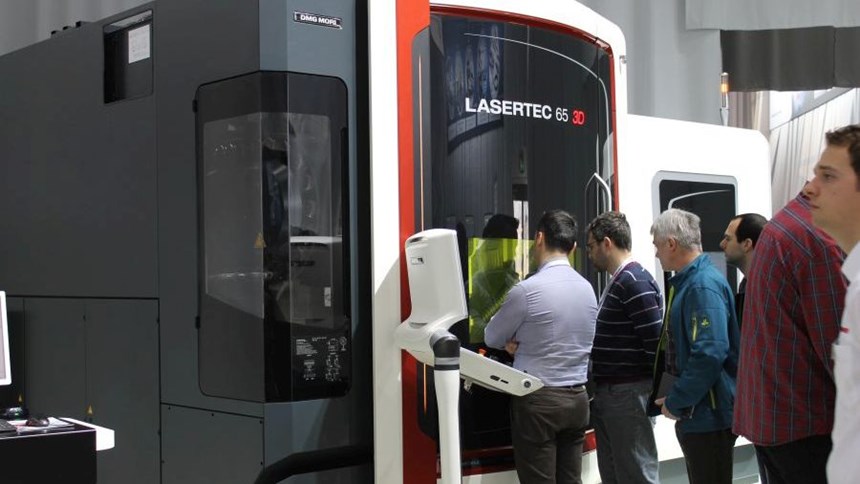

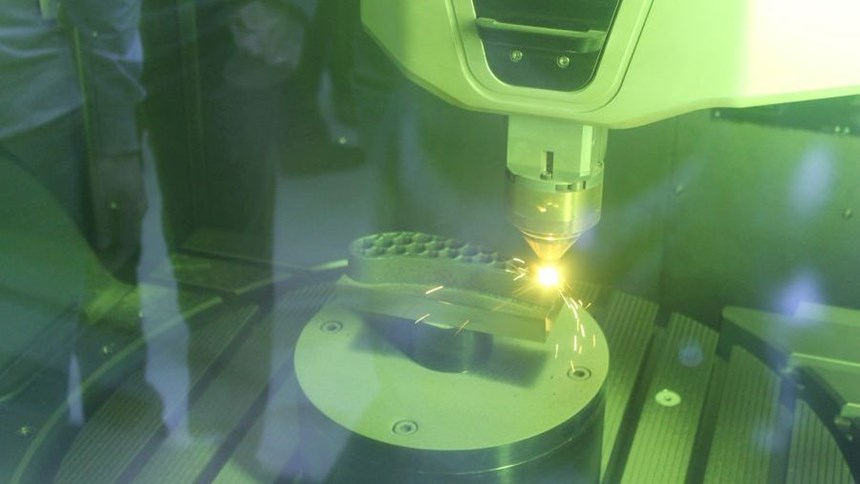

DMG MORI recently announced that it will now be offering an additive manufacturing (AM) machine based on powder-bed technology. By a majority shareholding of 50.1 percent in Realizer GmbH in Borchen, Germany, the group has strengthened its future technologies in AM. The selective laser melting (SLM) technology complements the company's existing AM offering, the Lasertec 65 3D for laser deposition welding and milling. The machines will be built in Bielefeld, Germany, and ready for series production.

As a pioneer of the powder-bed SLM process with more than 20 years’ experience, Realizer has advanced the technology to the level of mass production. It makes sense to partner with a company which is established in the market, says Dr. Thorsten Schmidt, CEO, DMG MORI USA. “I think it is clever to combine Realizer’s know-how with our knowledge of how a machine tool is built and how to potentially integrate AM into traditional industries,” he adds.

Patrick Diederich, managing director of Sauer GmbH, Germany, agrees.

“Machine tools are purchased as a long-term investment, and return on investment is an important factor. Therefore, additive machines must be built with the same rugged design principals as any other machine tool,” Diederich says. “We know that our customers need to produce parts at a competitive price, which means that the machines must be totally reliable and can run partially or totally automated, with as little human intervention as possible.”

Diederich considers AM to be complementary to conventional machining techniques not designed to replace them. In fact, he thinks that the integration in a manufacturing process and interaction with other more traditional machine tools, such as milling or turning centers, will be essential for the success of additive manufacturing.

“Ultimately, AM is valuable for the manufacture of parts that are not possible to be manufactured via traditional machining technologies today,” Diederich says. “Today, we manufacture and design parts according to a machine tool’s capability. We push the capability of a machine tool to its limit to produce the best parts. AM, on the other side, opens up opportunities to manufacture parts with a complexity that has not been possible using conventional machines.”

The potential of AM technology is huge. Diederich compares the rapid adoption of additive manufacturing technology we are seeing today with five-axis simultaneous milling about 15 years ago. “We were all fascinated by five-axis machine tools,” he remembers. “We were able to produce new and complex high-quality parts. However, nobody knew how profoundly it would change manufacturing. We used to ask ourselves ‘Five-axis machining is interesting, but what can I use it for?’. Then designers and engineers began to understand that quality improves, fixturing costs decrease, less machines are needed for production, etc. As a result, companies began to design products around the capability of five-axis machines. Now, the same is true for additive manufacturing. As soon as companies begin to understand how to design parts to their advantage based on the capability of additive machines, the adoption will be huge.”

However, there are currently some obstacles standing in the way of AM being more widely used. The main obstacle is knowledge, Diederich believes. Knowledge about the possibilities AM offers, about materials and about the design. Parts designed for additive manufacturing only require material where it is needed in contrast to milling, where you generate a lot of waste if you machine a part from a solid block of titanium, for instance. “Furthermore, we have to be aware that we have built up a knowledge-base that relies on what is known about traditional technologies,” Diederich says. “For example, a manufacturing specification suggests a particular material. This material may not be suitable for additive manufacturing. Consequently, companies must be aware of what their existing specifications are and perhaps welcome the new by not requiring a particular material, but instead specify particular material properties.”

But it is not only the knowledge and the machine itself which contribute to the successful implementation of additive technology in today’s manufacturing environment. According to Diederich, there are two other important factors determining the future success of AM technologies: the software driving the machines and process control.

“With Siemens NX we have a strong programming partner,” Diederich explains. “For us, AM is another manufacturing step, not an island solution. Any part going to the additive machine will be based on CAD data like any other part. Likewise, the job is not done when the part is finished on the additive machine. Postprocessing is almost always necessary, so the part will have to be machined conventionally after the AM process. It’s essential, however, that the whole manufacturing process is based on a single data platform.”

Furthermore, process control is essential, Diederich says. “Quality is essential. The first part must be as good as the last part. Therefore, the process has to be constantly monitored and controlled. This is particularly important if additive technology is to be accepted in the aerospace industry.”

Looking into the future, Dr. Schmidt anticipates that additive technology will not be fully integrated into high-volume production environments within the next five years, as cycle times will be a bottleneck. “However, there are lower volume production applications where AM is already providing cost reductions,” he adds. “In combination with the legacy AM markets of repair and rapid prototyping, additive manufacturing represents a great opportunity. Therefore, DMG MORI is committed to increase its additive product portfolio to account for 20 percent of sales in the future.”

Related Content

AM 101: Digital Light Synthesis (DLS)

Digital Light Synthesis (DLS) is the name for Carbon's resin-based 3D printing process. How it works and how it differs from stereolithography.

Read MoreUnderstanding HP's Metal Jet: Beyond Part Geometry, Now It's About Modularity, Automation and Scale

Since introducing its metal binder jetting platform at IMTS in 2018, HP has made significant strides to commercialize the technology as a serial production solution. We got an early preview of the just-announced Metal Jet S100.

Read MoreHow to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

Read MoreAM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

Read MoreRead Next

To Improve Performance of Compression Molded Composites, Add 3D Printed Preforms

9T Labs' Additive Fusion Technology enables the manufacture of composite structures with as much or as little reinforcement as is necessary, using 3D printed continuous fiber preforms to add strength just where needed.

Read MoreLooking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read MoreVideo: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

Read More