Renishaw to Introduce Additive Manufacturing System Aimed at Production

The first machine developed in-house by the company features a high-power laser and automation for industrial production via additive manufacturing.

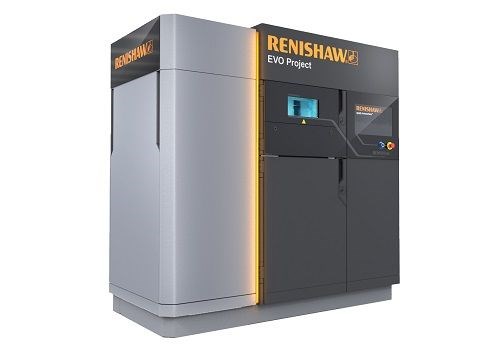

Renishaw has announced that it is developing a new additive manufacturing system designed and engineered specifically for production manufacturing. The machine, which the company has provisionally named the “EVO Project,” includes a 500-W laser, high-capacity filtration and automated powder handling.

Renishaw became an additive manufacturing OEM through acquisition in 2011. Now, this new machine will be the first the company has designed and engineered in-house, drawing on its own knowledge and background in production manufacturing. The new machine does not replace the Renishaw AM250 system, the company says, as this existing machine remains better suited for flexible manufacturing and research applications in which changes between materials are a requirement.

The new machine, by contrast, is designed for single-material industrial production. Powder handling is said to be almost entirely hands-off, while powder recirculation, recycling and recovery are all carried out within the inert atmosphere of the system.

Renishaw plans for the new machine to be available during the second half of 2015. Learn more here.

Related Content

-

How 3D Printing Will Change Composites Manufacturing

A Q&A with the editor-in-chief of CompositesWorld explores tooling, continuous fiber, hybrid processes, and the opportunities for smaller and more intricate composite parts.

-

3D Printed End of Arm Tooling Aids Automation

Frustrations with traditional end of arm tooling led Richard Savage to start 3D printing custom versions for injection molding applications, eventually founding a company to fill this niche.

-

Autonomous Cobot Automation Increases Production 3D Printer Output for Ford (Includes Video)

A mobile robot that travels to each Carbon machine to unload builds lets the automaker run an additional three to four builds per machine per day. Autonomous robots fit well with 3D printing, but their role in production will extend beyond just the additive machines.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)