High-Frequency Production

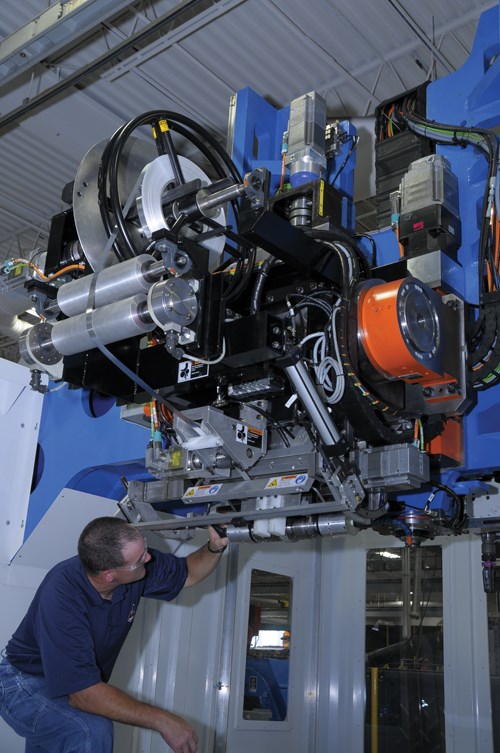

The additive process that grew out of ultrasonic welding provides an efficient way to produce complex work, including parts with embedded components and even parts made from dissimilar metals.

To gage how close additive manufacturing is to becoming a mainstream option for making metal parts, it is interesting to note this detail: Ultrasonic additive manufacturing machines from Fabrisonic of Columbus, Ohio, are programmed using a machining center’s CAM software.

Related Content

Additive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreAluminum Gets Its Own Additive Manufacturing Process

Alloy Enterprises’ selective diffusion bonding process is specifically designed for high throughput production of aluminum parts, enabling additive manufacturing to compete with casting.

Read MoreNew Electric Dirt Bike Is Designed for Molding, but Produced Through 3D Printing (Includes Video)

Cobra Moto’s new all-electric youth motocross bike could not wait for mold tooling. Parts have been designed so they can be molded eventually, but to get the bike to market, the production method now is additive manufacturing.

Read MoreHow Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MoreRead Next

GE Additive Rebrands as Colibrium Additive

As part of the brand name transition, both the Concept Laser and Arcam EBM legacy brands will be retired.

Read MoreVideo: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)