AI-Driven "Operating System" Makes Data Count

AI assistance could help additive manufacturing operations link engineering and design data to what is really happening on the factory floor.

Machine monitoring is not enough to make an additive manufacturing operation “smart.”

It can certainly make one smarter. However, even with deep utilization metrics and comprehensive, real-time dashboard displays, the intelligence required to improve is mostly human.

What if there was another intelligence working to derive insights from manufacturing data—a computerized assistant that thinks faster than any human and never makes mistakes, gets tired or lets emotion interfere with its recommendations? FactoryOS, a cloud-based, enterprise-wide “operating system” from software developer Oqton, uses artificial intelligence (AI) to provide just that. “You can almost think of it as a Google Maps for manufacturing,” says Ben Schrauwen, co-founder and CEO. “Instead of suggesting a faster route, the system provides different options for manufacturing a part.”

For instance, one Oqton customer 3D prints implants, crowns, bridges and other dental components at multiple facilities. “Our AI analyzes the part geometry, correlates to the success rates of similar parts and gives a price,” Schrauwen explains. “Then, it helps with all kinds of decisions—the printing orientation, the support structure, how to combine parts on the build plate—all based on what has worked well in the past. If something unexpected happens, it learns.”

“[Our AI] helps with all kinds of decisions—the printing orientation, the support structure, how to combine parts on the build plate—all based on what has worked well in the past. If something unexpected happens, it learns.”

Functionality extends beyond decisions directly related to the additive manufacturing process. To facilitate the system’s role as an enterprise-wide operating system, FactoryOS runs in a Web browser. As an open-source system built to comply with open standards, FactoryOS interfaces with any physical or digital asset a manufacturer might employ, from CAD software and individual machine controls to enterprise resource planning (ERP) and equipment monitoring systems. AI works in the background to feed customizable modules that present information relevant only to specific operational roles (accounting, scheduling, etc.).

The longer the AI works, the better the system’s virtual model of what “normal” looks like, whether that applies to an individual machine or process, the entire plant or operations across multiple facilities. The better the virtual model, the better the system’s ability to detect potential problems, actual problems and opportunities for improvement. Pop-up windows notify the user of deviations (or trends toward deviations) from the norm and offer advice about how best to respond. For example, on the level of the individual 3D printer, FactoryOS might ask whether a new alarm condition should be created when certain parameters reach levels deemed abnormal based on what the system “knows” about how the machine should perform when it’s well maintained.

The dental-component manufacturer mentioned above provides a good example of the system’s different AI-driven functionalities, beginning with quoting. Capable of analyzing hundreds of design files at once, the system returns what it believes to be a fair price based on historical trends for similar parts. If quoting is urgent, this work can be performed in seconds on some jobs, Schrauwen says. Alternatively, allowing the system more time to crunch the data can potentially result in a more accurate quote.

AI also makes scheduling dynamic by suggesting different sequences of operations or workstations based on decision-makers’ priorities and past outcomes for similar work. “It knows the state of the operation, including demand and capacity, which equipment is available, and the timing of all the maintenance cycles,” Schrauwen says. “If a machine goes offline for any reason or is unavailable, it dynamically reroutes the work.”

Given the need for information on cycle times, geometry and more, AI suggestions for quoting and scheduling are derived in part from the same data that informs manufacturing decisions for any given job. The more data the system processes, the better it becomes. For instance, the first 3D-printed crowns manufactured with guidance from FactoryOS required correcting the system’s suggestion for orienting parts on the build plate. However, after manufacturing enough of them, the system came to “understand” that the most important surface is the one in contact with the patient’s tooth. Now, it always suggests orienting crowns so that this portion faces up.

For each build, the system tracks cycle time, oxygen concentration, laser power, and various other critical parameters to build a model of what the ideal process should look like and correct itself over time. “Let’s say a part fails,” Schrauwen says. “It will auto-schedule that part to be completed on a different build, and it will also try to learn why it failed. Was it something fundamentally wrong with the process, or will it work next time? Was it a problem with the machine, or an operator mistake, or a mistake in engineering?”

The result, he says, is a continuous cycle of improvement. “There are a lot of assumptions manufacturers make—what are the yield estimates, how long will the build take—but assumptions are just that,” he concludes. “In reality, there are always deviations. And usually that data doesn’t feed back. It gets archived and no one does anything with it. Everybody talks about the digital thread solving these problems. We aim to commoditize the digital thread with a platform that ties design and engineering to what really happens on the shop floor.”

Related Content

Voxel Developing AI Alternative to Generative Design

Newly opened Ohio facility is where geometric cells are made and tested to inform the machine learning system that will “know,” without computation, what 3D printed form satisfies a given set of needs.

Read MoreMPI Launches AI Project to Create Material Reuse Management Tool for Metal 3D Printing

MPI is working with Additive Manufacturing Solutions and AMFG to create a versatile, commercial predictive material reuse management tool that will enable additive manufacturing to expand by introducing greater cost efficiencies.

Read More3D Printed "Evolved Structures" for NASA Exoplanet Balloon Mission: The Cool Parts Show #61

Generative design creates stiff, lightweight brackets for EXCITE mission monitoring planets orbiting other stars. The Cool Parts Show visits Goddard Space Flight Center.

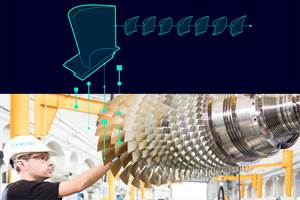

Read MoreSiemens’ Engineering HEEDS AI Simulation Predictor Optimizes Additive Manufacturing

The HEEDS AI Simulation Predictor empowers organizations to take full advantage of the digital twin to optimize products through advanced state-of-the-art artificial intelligence with built-in accuracy awareness.

Read MoreRead Next

How Machine Learning Is Moving AM Beyond Trial and Error

A Colorado alliance has found the link between AM and AI. Using machine learning to map the formula for successful metal 3D printing, researchers aim to know the right parameters for any new part with few or no test builds.

Read MoreGE Additive Rebrands as Colibrium Additive

As part of the brand name transition, both the Concept Laser and Arcam EBM legacy brands will be retired.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More

.png;maxWidth=300;quality=90)