3D Printing Impacts Production Mold Design

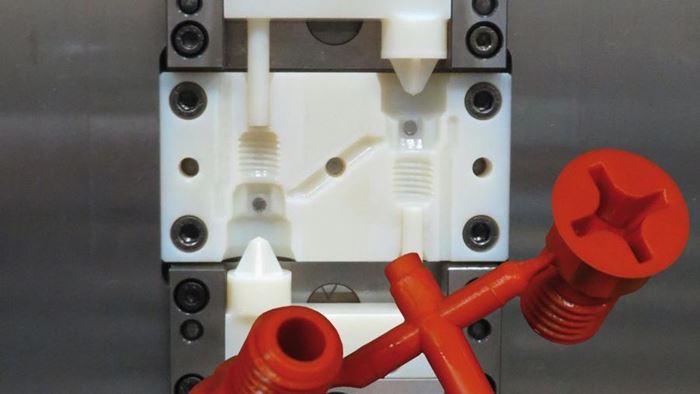

3D-printed cavities and cores serve as a testing ground to quickly prove out production mold design options.

3D-printed mold prototypes can reveal means of improving material choices and other variables prior to production. Hasco and Stratasys have been working with molders and moldmakers to provide a prototyping method that combines 3D-printed mold inserts and components via Stratasys expertise with quick-change mold systems and standard components from Hasco.

In one such application, an easy-to-mount sealing plug needed to be produced for a clamping fixture to seal a large number of threaded holes. An initial cost analysis and design review revealed that this plug type, which involved walled sections 12 mm (0.472 inch) thick, could not be economically produced by conventional injection molding. A prototype mold was needed to perform feasibility studies to determine the necessary mold design, process and material changes to make the sealing screw prototype parts and the subsequent production mold.

To speed prototyping, a quick-change mold system (standard steel plates with easily changeable cavities and cores) was selected and modified with standard slides from Hasco, and a standard ejector system and side rails were used. German moldmaker Canto 3D printed the mold cavity, core and slide faces with a Stratasys Connex 500 and placed them into the quick-change mold system, performed final fitting and sampled the prototypes, all within four days. Canto printed the cavity, core and slide faces within 6 hours instead of spending days machining, heat treating, re-machining and grinding. There were three versions produced between initial and final 3D printing.

“This prototyping method helped to quickly determine the proper size and shape of the part for moldability, and initially revealed that a steel cavity and core would not properly produce the end-use part, as thermal conductivity was a very important factor. These results were applied to the design of a final four-cavity production mold using a copper-bronze matrix to insure proper cooling requirements to produce a working part and larger final part quantities,” says Brenda Clark, engineering manager for Hasco America.

This four-cavity production mold, incorporating a quick-change mold system, was produced using a patented sintered metal rapid tooling process with a 3D filigree network of copper-bronze and a surface coating of tungsten carbide. This process can be used to coat steel or to produce cavities and cores, as was done in this sealing screw part application. As a result, these production cavities and cores are similar to steel ones, says Clark, but offer increased absorption and faster heat release (up to five to 10 times higher thermal conductivity than conventional tool steels). This level of thermal conductivity helps to produce a thicker-walled part, which allows the mold to “set up” or cure properly in an optimal amount of time while achieving the correct part’s final form.

The key lesson learned was that material knowledge is essential when moving from the manufacture of prototype parts to end-use parts. Designers must understand material differences between prototype and production molding and how materials cure and react to the materials being molded around them.

According to Clark, this prototype project also uncovered a faster way to create more realistic prototypes in small batches; reduced the time and cost requirements for modifications; quickly revealed the need to change the original sealing screw design to decrease wall thickness; reduced the time and costs required for redesign and further testing; sped up the process for finalizing sizing; and allowed all 3D data to be created, adjusted and finalized for final production before any steel was cut.

In the end, a better production mold was able to be manufactured based on the prototypes produced from the 3D-printed inserts. Hasco and Stratasys are currently working with moldmakers and molders that are interested in exploring options like this as an ongoing initiative. “This combination prototyping option is not appropriate for every part, so it is important to find the right application. Working together with technology suppliers will help determine if a part will be best served with this option,” says Clark.

Related Content

Casting With Complexity: How Casting Plus 3D Printing Combine the Strengths of Both

Aristo Cast is advancing a mode of part production in which casting makes the part, but 3D printing enables the geometry.

Read More3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreAluminum Gets Its Own Additive Manufacturing Process

Alloy Enterprises’ selective diffusion bonding process is specifically designed for high throughput production of aluminum parts, enabling additive manufacturing to compete with casting.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read MoreRead Next

Video: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

Read MoreTo Improve Performance of Compression Molded Composites, Add 3D Printed Preforms

9T Labs' Additive Fusion Technology enables the manufacture of composite structures with as much or as little reinforcement as is necessary, using 3D printed continuous fiber preforms to add strength just where needed.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More

.png;maxWidth=300;quality=90)