Horizon Microtechnologies’ Micro AM for Conductive, Environmentally Resistant Parts

The company has developed a template-based 3D microfabrication technology that gives manufacturers the ability to add conductivity to all or selected parts of a 3D-microfabricated template.

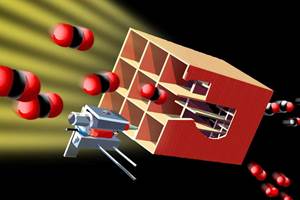

Horizon Microtechnologies has developed a template-based 3D microfabrication technology that gives manufacturers the ability to add conductivity to all or selected parts of a 3D-microfabricated template. Photo Credit: Horizon Technologies

Horizon Microtechnologies says its template-based 3D microfabrication technology is effectively a mechanism to exploit the usefulness of polymer micro additively manufactured (micro AM) 3D microstructures (the template). This technology is well suited for previously unserved areas of industry by adding material and functionality to the microstructure, typically with a coating process.

The company says it is now involved in numerous application-specific discussions with manufacturers across a variety of industry sectors. It is said the technology meets the demand from companies that want to benefit from the advantages and opportunities that exist through the use of micro AM, but want parts that have functionality impossible due to limited palette of materials that micro AM is able to process.

“We have researched and developed our template-based 3D microfabrication technology over many years, and while this is done in consultation with manufacturers and sensitive to market demands and dynamics, only when you commercially launch can you see and assess the level of real practical interest,” says Andreas Frölich, Horizon Microtechnologies CEO. “Since announcing the commercial availability of our technology, we have been somewhat overwhelmed by the highly qualified and application-specific nature of the conversations we are now having with customers.”

Frölich says the reason for this is to be expected in that its technology largely enhances the functionality of additive manufacturing (AM), specifically micro AM, which has only recently evolved into a repeatable and reliable area of AM for industrial applications.

“AM has been recognized across industry as affording manufacturers access to an agile, cost-effective and versatile technology that promotes hitherto impossible geometric complexity while at the same time democratizing manufacturing,” Frölich adds. “Our template-based 3D microfabrication technology opens up the power of AM to sectors that were until now unable to exploit it due to restricted material options, which, in turn, restricted part functionality.”

Horizon Microtechnologies has developed a post-build coating technology that builds upon the opportunities afforded through the use of micro AM-produced parts by adding functionality, specifically conductivity and environmental resistance. To introduce conductivity, once the part is produced on a polymer AM platform, it is either wholly or selectively coated with a conductive layer.

The company can even coat difficult areas homogeneously, such as long narrow channels and undercuts. In addition, microfabricated 3D templates can also be coated with metal oxides to make parts compatible with aggressive chemical environments and, in some cases, can notably increase the resistance to high temperatures and mechanical stresses. The ability to add conductivity to all or selected parts of a 3D microfabricated template is well suited for manufacturers of electrodes, electrical sensor heads and ESD-safe components.

“When focused specifically on electrodes, we are able to design an electrode geometry almost arbitrarily while maintaining manufacturability through the use of micro AM 3D templates,” Frölich says. “Using micro AM as opposed to traditional manufacturing processes allows for more flexibility when it comes to 3-dimensional placement of active electrode areas, stiffness (or lack of stiffness) of the electrodes and electrical properties of the electrode due to enhanced control over the inductance and capacitance. We also have the ability to make electrodes from different conductive materials to cater for biocompatibility/bioinertness.”

While Horizon’s coating process is agnostic to part geometry and complexity, if selective coating is required, this needs to be accounted for at the design stage of product development. Because of this, Horizon works with customers to optimize outcomes using design for micro AM and design for template-based microfabrication expertise.

- Listen to this episode of AM Radio as Peter Zelinski and Julia Hider zoom in on micro 3D printing, including discussion of the opportunities and challenges of 3D printing on a micro scale.

Related Content

BPMI Chooses Velo3D Metal 3D Printing System to Produce Parts for U.S. Naval Nuclear Propulsion Program

The fully integrated 3D printing solution will be operated by ATI in a newly established facility that will provide the U.S. Naval Nuclear Propulsion Program with alternatives to cast parts.

Read MoreDOE Awards Nearly $3 Million to Develop Additive Manufacturing of Modular Wind Blades

The industry partners received the award to develop automation in additive manufacturing of tooling for large-scale wind blades that can accommodate continuous changes in blade geometry and scale.

Read More3D Printed Reactor Core Makes Solar Fuel Production More Efficient

The solar reactor uses water and CO2 from the air and sunlight as the energy source to produce carbon-neutral liquid fuels, for example, solar kerosene for aviation.

Read MoreSafer Nuclear Energy: 3D Printed Silicon Carbide Fuel Forms

Binder jetting provides a way to create pure silicon carbide fuel structures that can withstand the harsh environment of a nuclear reactor and provide a strong barrier against the release of radionuclides.

Read MoreRead Next

To Improve Performance of Compression Molded Composites, Add 3D Printed Preforms

9T Labs' Additive Fusion Technology enables the manufacture of composite structures with as much or as little reinforcement as is necessary, using 3D printed continuous fiber preforms to add strength just where needed.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreLooking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read More

.png;maxWidth=300;quality=90)