Composites

Eaton Developing Carbon-Reinforced PEKK to Replace Aluminum in Aircraft Air Ducts

3D printable material will meet ESD, flammability and other requirements to allow for flexible manufacturing of ducts, without tooling needed today.

Peter Zelinski

Editor-in-Chief, Additive Manufacturing

CRP Technology’s Windform SL Is Lightweight, Rigid Composite for SLS, LPBF

Windform SL is well suited for the the production of sophisticated, efficient components across various fields, from aerospace to automotive, ensuring light weight without the need to reduce thickness.

Read MoreAircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

Read MoreLithoz Invests in AMAREA 3D Printing Technology Which Combines Up to Six Different Materials in a Single Print Run

The company is looking to actively support a new dimension of 3D printed, functionally graded components.

Read MoreMarkforged 3D Printing Simulation Software Validates Composite Part Strength

The virtual testing validates the strength of advanced composite parts and automatically optimizes print parameters to lower cost and speed production.

Read MoreVideo: Reinforcing (and Joining) Parts After 3D Printing

Reinforce 3D has developed a method that can be applied to strengthen 3D printed parts by feeding continuous fiber and resin through them. The technique also enables joining parts of various materials and manufacturing methods.

Read MoreProlay 7Q 3D Offers PLTM Technology for Polymer, Composite Additive Manufacturing

The Prolay 7Q can produce components 1.5 to 5 times faster than conventional AM methods and produce parts with different layer thicknesses in a single process.

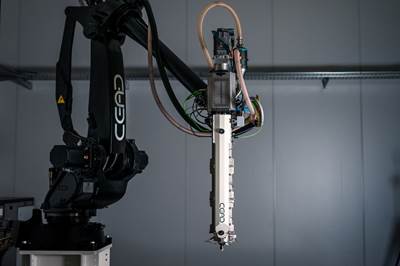

Read MoreCEAD and Adaxis Integrate Technologies for More Efficient Robotic Large Format 3D Printing

CEAD’s methodology for large-format 3D printing converges within Adaxis’ AdaOne software for the Flexbot platform, giving Flexbot users a smoother, more efficient experience with increased consistency, reliability and build quality, while minimizing potential issues.

Angela Osborne

Managing Editor, Gardner Business Media

Next-Gen Horse Trailers to Be Built With Robotic 3D Printing

Double D Trailers is currently developing a prototype horse trailer that will be made with large-format additive manufacturing. The technology brings potential benefits for labor, weight and design features to this subset of recreational vehicles.

Read MoreMarkforged’s FX10 Industrial 3D Printer Replaces Metal Parts With Advanced Composites

This fifth-generation print system features built-in automation for quality assurance and print routines designed to deliver strong, accurate parts every print.

Read MoreDOE Awards Nearly $3 Million to Develop Additive Manufacturing of Modular Wind Blades

The industry partners received the award to develop automation in additive manufacturing of tooling for large-scale wind blades that can accommodate continuous changes in blade geometry and scale.

Read MoreAIM3D Study Shows 3D Printing Ultem 9085 Pellets Offers Lower Cost, Higher Tensile Strength

The material qualification testing indicates many benefits of creating components with AIM3D’s ExAM 510 printer using the composite extrusion modeling process, which uses standard pellets rather than the more expensive filaments required by other platforms.

Read MoreShape Lab Develops MyCera to Reinforce 3D Printed Clay Structures

Mycelium is an intelligently oriented fiber reinforcement that can increase the structural performance of 3D printed unfired clay elements and enable bio-welding of fired elements.

Read MoreCatalysis Additive Tooling Licenses 3D Printed Tooling Technology in Europe

The innoMold company will spearhead the tool manufacturing operating under the name “Catalysis Additive Tooling GmbH,” beginning operations in October 2023.

Read MoreAirtech Qualifies Dahltram Resins for Integration With Caracol’s Heron LFAM Platform

The companies say this qualification will support Caracol in its efforts to offer Airtech’s Dahltram resins to its customers across the globe.

Angela Osborne

Managing Editor, Gardner Business Media

Louisville Slugger Uses Formlabs Technology to Accelerate Innovation

Louisville Slugger relies on Formlabs’ Form 3 stereolithography 3D printer to create both prototypes and manufacturing aids for designs of the composite and aluminum bats swung by youth and collegiate players.

Read More3D Printed Preforms Improve Strength of Composite Brackets: The Cool Parts Show Bonus

On this episode, we look at a pin bracket for the overhead bin of an airplane made in two composite versions: one with continuous fiber 3D printed reinforcements plus chopped fiber material, and one molded from chopped fiber alone.

Read MoreTo Improve Performance of Compression Molded Composites, Add 3D Printed Preforms

9T Labs' Additive Fusion Technology enables the manufacture of composite structures with as much or as little reinforcement as is necessary, using 3D printed continuous fiber preforms to add strength just where needed.

Read MoreBetter, More Compact Radio Frequency Devices Through 3D Printing

3D printing technology company Fortify is applying its photopolymer process and material developed with Rogers Corporation to serve the expanding RF market.

Read MoreNexa3D Expands Resin Portfolio With Ceramic, Flexible, Clear Materials

Nexa3D worked with material experts at BASF and Henkel to validate custom formulations for its ultrafast fleet of industrial and desktop 3D printers.

Read More8 Social Media Posts About Additive Manufacturing: AM Radio #34

Cost savings, modifications, large-format AM and more. In this episode of AM Radio, we discuss what people are saying about additive manufacturing on social media.

Read MoreJuggerBot 3D Awarded $4 Million by Air Force to Develop Large Format Hybrid Additive System

The project focuses on advancing the ability to print a thermoset composite material that can transform the way an aircraft structure is designed, fabricated and sustained for limited-life aircraft.

Angela Osborne

Managing Editor, Gardner Business Media

Advancing Additive Manufacturing With a CATCH and Release Approach

Solutions for energy efficiency, sustainability, part repair and more are developing at Siemens’ Charlotte Advanced Technology Collaboration Hub (CATCH) in North Carolina.

Read MoreEvaluating the Printability and Mechanical Properties of LFAM Regrind

A study conducted by SABIC and Local Motors identified potential for the reuse of scrap reinforced polymer from large-format additive manufacturing. As this method increases in popularity, sustainable practices for recycling excess materials is a burgeoning concern.

Read More3D Printed Spares, Electrification and Cool Parts: Top 10 Stories of 2022: AM Radio #31

Our top articles and videos from 2022 reflect increasing use of additive manufacturing for replacement parts; growing applications for electric motors; and a maturing user base. Read through the top 10 list or listen to the AM Radio podcast episode all about these stories.

Read MoreZortrax Offers Metal Systems for Producing Complex End-Use Parts

In addition, the company also offers Victrex AM 200 filament, which has a lower melting point than PEEK and can be extruded in lower temperatures.

Read More3D Printing Method for Complex Metal-Plastic Composite Structures

Researchers from Japan and Singapore have developed a new 3D printing technique to create precise patterns on the external and internal surfaces of 3D plastic structures.

Read More9T Labs, Purdue Partner to Advance Composite Use in Structural Aerospace Applications

The collaboration is working to define a new composite manufacturing standard that enables users to produce structural composite parts as easily as metal parts.

Read More