Markforged

480 Pleasant St.

Watertown, MA 02472 US

866-496-1805

markforged.com

IS THIS YOUR COMPANY?

As Seen On Additive Manufacturing

Markforged Supplies the Following Products

- for Composite Parts

- for Metal Parts

- for Polymer Parts

- Material Extrusion

Editorial, News, and Products

-

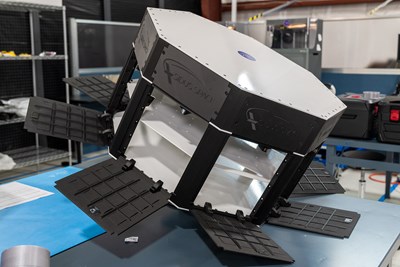

Sidus Space Successfully Launches LizzieSat Hybrid 3D-Printed Satellite

The hybrid 3D-printed satellite was manufactured using Markforged 3D printers for parts that would be incredibly lightweight, durable and custom to the structure to ensure the satellite remains intact during launch and works properly for its full life span in space.

-

Hawk Ridge Systems and DyeMansion Forge Partnership to Integrate Software and Hardware in Additive Manufacturing Workflow

Collaboration creates a one-stop-shop for all the tools and software needed to create precision products that look, feel and function properly. Now, Hawk Ridge Systems’ integrated solution portfolio will include a complete print-to-product workflow with DyeMansion’s Powershot C, Powershot S, DM60 and Powerfuse S postprocessing solutions.

-

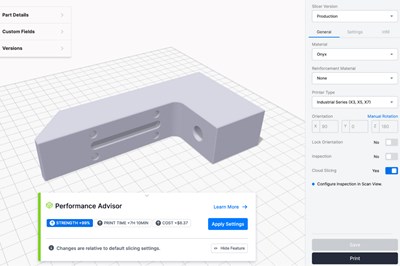

Markforged’s Performance Advisor Accelerates, Simplifies Part Simulation

Markforged’s Performance Advisor technology is use-case independent while being able to fully automate and optimize the performance of a part.

-

Do Distributors Dream of Digital Inventory? Würth Additive Group Does

It’s more than a dream for Würth Additive Group and its parent company, in fact. Along with supplying additive equipment, the group is now developing solutions for sourcing 3D printed parts in a reliable, elastic digital inventory model.

-

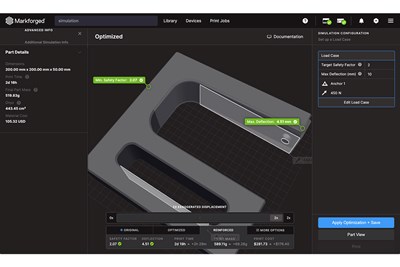

Markforged 3D Printing Simulation Software Validates Composite Part Strength

The virtual testing validates the strength of advanced composite parts and automatically optimizes print parameters to lower cost and speed production.

-

Markforged’s FX10 Industrial 3D Printer Replaces Metal Parts With Advanced Composites

This fifth-generation print system features built-in automation for quality assurance and print routines designed to deliver strong, accurate parts every print.

-

Markforged Reformulates H13, D2 Tool Steel for More Flexible, Less Brittle Filaments

The new filaments are reformulations of Markforged’s most popular tool steels.

-

Markforged’s Digital Source Platform Enables Printing Parts On-Demand

The platform enables manufacturer-certified parts to be licensed and printed at the point of need.

-

How Acquisition and Investment Activity Affects AM Users and Adopters: AM Radio #40

Stephanie Hendrixson and Peter Zelinski discuss how the corporate and financial developments in additive manufacturing play out for current and prospective users of AM technology, and where this activity is likely to lead.

-

Additive Wins on Cost, Plus Process Monitoring and More from RAPID + TCT 2023: AM Radio #38

Additive manufacturing is finding success as a cost-effective manufacturing method. New options for process monitoring are now available. DED is getting more precise. 3D printed chairs! What we learned and observed at RAPID + TCT 2023.

-

3D Printed Camera Components Capture "Avatar: The Way of Water" Film

SNL Creative provided an additive manufacturing solution for the stereoscopic camera rigs used by the production team during the creation of the new Avatar film. The custom-designed camera components met the rigorous requirements for filming and offered a modernized alternative for future film usage.

-

How AM Enables Cobot Automation for Thyssenkrupp Bilstein (Includes Video)

The shock absorber maker has responded to its staffing shortages through extensive use of collaborative robots. In-house 3D printing makes this possible by providing the related hardware needed to complete the cobot-automated cells.

-

Tackling Traceability in Production AM

PrintParts’ experience as New York City’s prime contractor for 3D printed nasal swabs shows how traceability, such as the company’s SmartParts solution, can address challenges and improve production.

-

Saving Time and Money on the Shop Floor with AM

Some of the most popular ways AM is presented miss some of the most practical and valuable ways AM can be used.

-

Markforged Adds Simulation Feature to Additive Manufacturing Software

The software’s virtual testing can validate the strength of advanced composite parts and automatically optimize print parameters to lower cost and speed production.

-

Markforged Partners With 3YourMind to Scale Automation of AM

3YourMind delivers end-to-end additive manufacturing workflow by integrating Markforged’s Eiger software to facilitate Industry 4.0 adoption.

-

Additive Manufacturing Production at Scale Reveals the Technology's Next Challenges: AM Radio #28

Seemingly small issues in 3D printing are becoming larger problems that need solutions as manufacturers advance into ongoing production and higher quantities with AM. Stephanie Hendrixson and Peter Zelinski discuss 6 of these challenges on AM Radio.

-

Closing the Gap in Funding Additive Manufacturing

There is a large funding gap in advanced manufacturing and filling this void will take commitment from private organizations and the government to educate investors about potential returns within the complex $65 billion manufacturing technology industry.

-

3D Printing Supports Induction Coils — and Emergency Needs

As a participant in Michigan’s Project DIAMOnD initiative, Tucker Induction Systems received a 3D printer to use any way it saw fit, provided the capacity remains available in case of emergency. Use cases and lessons learned as part of this distributed manufacturing network.

-

Is a Functional 3D Printer Network Possible? Automation Alley’s Project DIAMOnD and the Industry 4.0 Future

The initiative that placed 3D printers at more than 300 Michigan manufacturers is laying the groundwork for a future in manufacturing that is digital, distributed and largely additive.

-

Are the Seven Families Still Valid for Describing 3D Printing Processes? AM Radio #21B

A conversation about the additive manufacturing processes that do not easily fit the accepted categories, and whether this mismatch means it is time for the categories to change.

-

Markforged Acquires Digital Metal

Acquisition accelerates Markforged’s expansion into mass production of end-use metal parts through Digital Metal’s reliable, production-grade binder jetting solution.

-

Markforged Expands Offerings with Larger 3D Printer

The FX20, Markforged’s largest and fastest 3D printer, is appearing at IMTS for the first time.

-

3D Printed Putter Tailored to the Golfer: The Cool Parts Show #49

An engineering student in South Africa used metal and polymer 3D printing in tandem to create a putter customized to the individual golfer’s swing.

-

3D Printed End of Arm Tooling Aids Automation

Frustrations with traditional end of arm tooling led Richard Savage to start 3D printing custom versions for injection molding applications, eventually founding a company to fill this niche.

-

Araqev’s QC Software Helps Limit Design Iterations

The company says the software’s machine-learning models enable it to derive modifications to the nominal designs, so when the modified designs are printed, they will exhibit fewer shape deviations compared to when original designs are printed.

-

3 Types of 3D Printed Tooling for Injection Molding: AM Radio #16A

3D printed tooling for injection molding, including mold inserts, components and end of arm tooling, were on display at the Plastics Technology Expo.

-

How Siemens Energy Applies Additive Manufacturing for Power Generation and More

At an applications center in Orlando, Florida, a small team of AM specialists is spanning industries by 3D printing parts to support both Siemens Energy power generation systems and external customers.

-

Markforged Acquires Teton Simulation

Integration of Teton’s cloud native simulation software into Markforged’s Digital Forge platform will enable manufacturers to validate advanced composite parts for demanding production applications.

-

For Automated Machining Business, 3D Printing’s Value-Add Keeps Adding Up

Through robot grippers, assembly aids, custom kits and coolant hardware, additive manufacturing impacts every stage of production.

-

Markforged’s Precise PLA Expands Capabilities for Complete Product Life Cycle

Material expands Markforged applications from functional carbon fiber and metal parts to cost-effective design validation and rapid prototyping.

-

A Conversation on Formnext: Trends in 2021, and Formnext USA: AM Radio #8

The Frankfurt, Germany, trade show resumed in-person in 2021 and laid the groundwork for future events in North America. AM Radio hosts Stephanie Hendrixson and Peter Zelinski discuss both in this episode, which includes a guest appearance by Gardner Business Media president Rick Kline.

-

10 Trends from Formnext 2021

The largest trade show for additive manufacturing technology returned with an in-person format this November. Editors Peter Zelinski and Stephanie Hendrixson share sights and trends from the event.

-

Markforged’s Eiger Fleet Enables More Control, Automation of Distributed Manufacturing

Cloud-based software solution manages distributed manufacturing operations on an enterprise and global scale with increased efficiency and insight.

-

Impressions and Trends from RAPID + TCT 2021: AM Radio Bonus

Peter Zelinski, Stephanie Hendrixson and Julia Hider discuss what they saw, heard and learned at RAPID + TCT 2021 in a special episode of the AM Radio podcast plus slideshow.

-

Metal and Composite AM Grant US Army Significant Savings

Markforged’s printers and proprietary Eiger software have enabled the U.S. Army to save over $9,000 per part for some critical training components.

-

FX20 3D Printer Produces High-Temperature, Reinforced Thermoplastics

The company says the Markforged printer enables the robust production of lightweight, advanced composite parts.

-

Job Shop’s AM Journey Takes It from Production to Tooling

Despite the fact that RPG was prepared to start with production metal additive manufacturing, the job shop couldn’t ignore the benefits of 3D-printed tooling.

-

Metal 3D Printing in the CNC Machining Job Shop

For metalworking businesses looking for a metal 3D printing option free of the concerns of handling metal powder, metal fused filament fabrication provides additive capabilities with easy implementation and material flexibility.

-

10 Examples of 3D Printed Tooling

Additive manufacturing can aid conventional manufacturing through the production of tooling. This article showcases 10 clever uses of 3D printed tooling.

-

AI-Driven Adaptive Manufacturing Software Aims to Self-Correct 3D Printing (Includes Video)

The AI software platform Blacksmith from Markforged shares feedback from its cloud-connected fleet of printers to identify and correct distortions in a 3D-printed part.

-

3D Printed Tool for CNC Machining: The Cool Parts Show #17

Guhring uses additive manufacturing to make an end mill with optimized internal channels. We visit a machine shop to test the tool on this episode of The Cool Parts Show.

-

Blacksmith Promises Adaptive Manufacturing for 3D Printing and Beyond

Blacksmith, an artificial intelligence (AI) solution from Markforged, promises to adjust part designs and processes based on real results. The implication is better, easier 3D printing — but also adaptive manufacturing more broadly.

-

10 Impressions of Rapid + TCT 2019

The largest additive manufacturing exposition in North America is now a mature industry trade show. Here is what the editors of Additive Manufacturing Media saw at this year’s Rapid + TCT.

-

3D-Printed Tooling and the Mindset Change at Pella

For the window and door maker, 3D printing for tooling and machine components is “not just another tool, but a whole other toolkit.” However, winning widespread acceptance and understanding was the most important challenge.

-

FFF 3D Printing for Metal: Sintering Can Wait

Separating 3D printing from high-temperature processing is part of how the Markforged Metal X realizes a price less than established metal AM equipment.

-

One-Offs Without Tradeoffs

Does it have to be expensive to produce a one-off part? Does the one-off have to fall short of the manufactured part’s properties? A Boston-area 3D printer maker has an idea for how to produce components that are both low quantity and industrial quality.