Stratasys’ Carbon Fiber Material is Stronger, Stiffer ABS

Strong, lightweight, ABS-based material is specifically formulated for applications such as manufacturing tooling, jigs and fixtures.

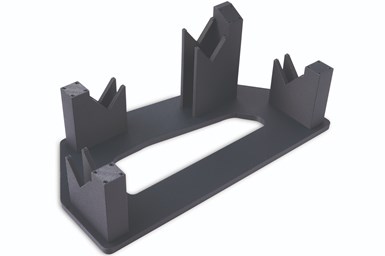

ABS-CF10 offers excellent stiffness for alignment tools like this weldment fixture.

Stratasys’ FDM ABS-CF10 is an ABS-based carbon fiber material for its line of F123 Series 3D printers. It’s the first composite material developed for that platform.

The material properties of FDM ABS-CF10, featuring 10% chopped carbon fiber, make it a compelling alternative to metal parts, the company says. The material is 15% stronger and more than 50% stiffer than standard ABS, without the weight of metal, and can be printed with a high degree of accuracy. QSR Support water-soluble material makes it possible to 3D print intricate and complex parts without time-consuming manual support removal.

Carbon fiber materials have proven popular on Stratasys’ industrial-scale FDM 3D printers for a variety of end-use applications such as jigs, fixtures and tooling. The company says that FDM ABS-CF10 makes carbon fiber much more accessible to the engineering and manufacturing community for use with its high-performance F170, F270 and F370 3D printers.

Manufacturers are increasingly turning to 3D-printed carbon fiber materials because it’s strong, versatile and lightweight, the company says. Using the FDM ABS-CF10 with Stratasys’ 3D printers means that 3D printing parts that were historically made of metal can lead to a significant cost reduction compared to machining the part out of aluminum, while also reducing overall part weight.

Stratasys’ internal analysis suggests the additive manufacturing market for polymer jigs and fixtures is expected to grow at a 14.2% annual rate between 2019 and 2023, to nearly $600 million, which is double the growth rate of the prior four years. With its FDM ABS-CF10 material, Stratasys is particularly focused on addressing applications in the aerospace, automotive, industrial and recreational manufacturing industries. Parts applications include end effectors used with industrial robots, ergonomic aids such as lift assists and hand tools, and alignment fixtures on assembly lines.

Related Content

-

3D Printing Supports Induction Coils — and Emergency Needs

As a participant in Michigan’s Project DIAMOnD initiative, Tucker Induction Systems received a 3D printer to use any way it saw fit, provided the capacity remains available in case of emergency. Use cases and lessons learned as part of this distributed manufacturing network.

-

Louisville Slugger Uses Formlabs Technology to Accelerate Innovation

Louisville Slugger relies on Formlabs’ Form 3 stereolithography 3D printer to create both prototypes and manufacturing aids for designs of the composite and aluminum bats swung by youth and collegiate players.

-

Evaluating the Printability and Mechanical Properties of LFAM Regrind

A study conducted by SABIC and Local Motors identified potential for the reuse of scrap reinforced polymer from large-format additive manufacturing. As this method increases in popularity, sustainable practices for recycling excess materials is a burgeoning concern.