Laser Mechanisms FiberWeld DH Designed for Production Applications

RAPID 2020: Laser Mechanisms’ FiberWeld DH is a high power, laser wire direct energy deposition (DED) head for processing macro-scale industrial and aerospace components and tooling.

Share

Read Next

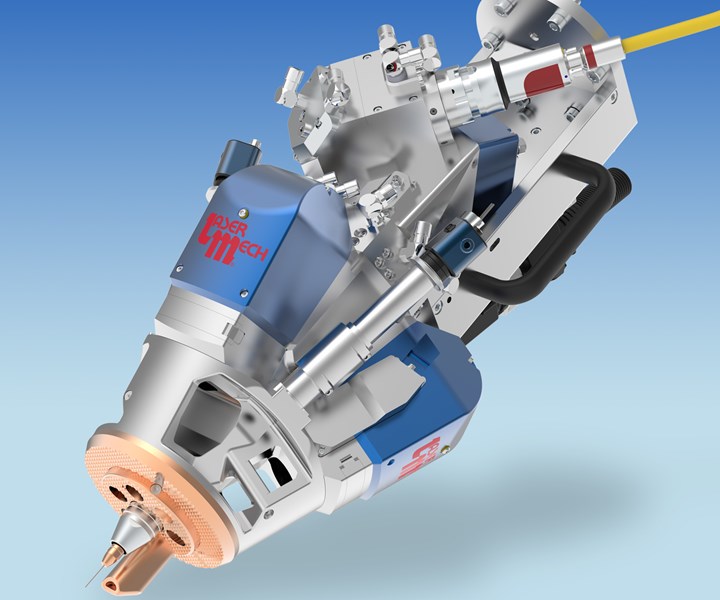

Laser wire direct energy deposition head.

Laser Mechanisms’ FiberWeld DH is a high power, laser wire direct energy deposition (DED) head for processing macro-scale industrial and aerospace components and tooling.

Engineered for high duty cycle production applications, FiberWeld DH features direct-cooled reflective optics, back reflection protection and wire feed. The head’s advanced optical design permits filler wire to be fed directly into the beam path – right into the center of the melt pool. This allows the deposition process to have total directional independence. In addition, FiberWeld DH’s easily accessible, protective cover glass extends the life of internal optics.

Related Content

-

7 Lessons From General Atomics on AM for Aircraft Part Production

A manufacturing leader overseeing the way additive manufacturing is transforming unmanned aerial systems (UASs) offers observations about succeeding with 3D printing as an aircraft production process.

-

Making Sense of Data from Directed Energy Deposition (DED)

“It should be easier to qualify an additive part than a casting,” says Formalloy CEO Melanie Lang. The company’s tools for capturing and analyzing data are bringing this vision closer to reality.

-

500-Pound Replacement Part 3D Printed by Robot: The Cool Parts Show #50

Our biggest metal cool part so far: Wire arc additive manufacturing delivers a replacement (and upgrade) for a critical bearing housing on a large piece of industrial machinery.