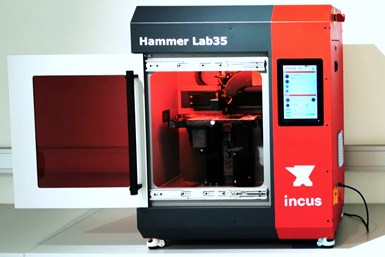

Incus Hammer Lab35 Offers Economic Protoyping, Small-Scale Production

Metal 3D printer has potential to increase performance and reduce costs for small and mid-scale production, as well as manufacture parts featuring complex geometries.

Hammer Lab35 3D metal printer

The Incus Hammer Lab35 metal 3D printer is capable of printing intricate geometries for functional prototypes and pre-series manufacturing. It utilizes the lithography-based metal manufacturing (LMM) process developed by Incus to provide economic prototyping and small-scale production using metal injection molding (MIM).

According to the company, the Incus LMM process technology and its flagship series machine, Hammer Lab35, give manufacturers superior feature resolution, surface aesthetics and mechanical properties for part sizes <200 g —a combination achieved for the first time in metal AM. With a print speed of up to 100 cm3/hr. and a lateral resolution of 35 µm, the Hammer Lab35 printing solution is designed to deliver the best quality parts. The company says the process can be easily integrated into existing MIM production lines or research and development departments as an option for small-scale production and prototyping.

Two Hammer Lab35 machines are in operation at the Institute for Precious and Technology Metals at Pforzheim University and its spin-off company, Metshape. With this collaboration, the process and system are reviewed and tested, and new materials and applications are being developed. This valuable feedback helps Incus to adapt the machine and the feedstocks to the needs of the manufacturing industry, increasing performance and reducing costs for small and mid-scale production, as well as manufacturing parts featuring complex geometries.

Related Content

-

New Electric Dirt Bike Is Designed for Molding, but Produced Through 3D Printing (Includes Video)

Cobra Moto’s new all-electric youth motocross bike could not wait for mold tooling. Parts have been designed so they can be molded eventually, but to get the bike to market, the production method now is additive manufacturing.

-

3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

-

How Siemens Energy Applies Additive Manufacturing for Power Generation and More

At an applications center in Orlando, Florida, a small team of AM specialists is spanning industries by 3D printing parts to support both Siemens Energy power generation systems and external customers.