Hexcel’s HexPEKK EM Offers Electromagnetic Shielding, Radar Absorption

Composite components are flight-ready after printing, omitting the need for costly and time-consuming secondary processing steps.

Share

Read Next

HexPEKK EM composite components are flight-ready after printing, omitting the need for costly, time-consuming secondary processing steps.

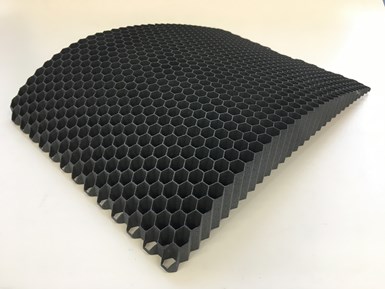

Hexcel’s HexPEKK EM is an electrically conductive, high-performance, PEKK-based thermoplastic carbon fiber composite additive manufacturing (AM) material that integrates advanced electromagnetic (EM) performance within complex 3D-printed components for the commercial aerospace, defense and military sectors.

The company says that HexPEKK EM composite components are flight-ready after printing. Formulated specifically to meet the static electricity management, electromagnetic shielding and radiation absorption requirements of advanced aircraft applications, the PEKK carbon-fiber-blended material delivers unique electrical performance. Manufactured using the aerospace industry-qualified HexAM process, HexPEKK EM components are said to exhibit best-in-class environmental, operational temperature and chemical-resistant performance attainable in the aerospace industry.

By integrating this enhanced EM performance into AM components, HexPEKK EM parts do not require costly and time-consuming secondary processing steps, such as the application of conductive coating for the management of electromagnetic interference or radiation absorption. Target applications for HexPEKK EM cover a broad range of products, including exterior surfaces, leading edges, air inlets, electronic enclosures and cockpit structures for commercial airplanes, military aircraft, helicopters and UAV components.

Related Content

-

Louisville Slugger Uses Formlabs Technology to Accelerate Innovation

Louisville Slugger relies on Formlabs’ Form 3 stereolithography 3D printer to create both prototypes and manufacturing aids for designs of the composite and aluminum bats swung by youth and collegiate players.

-

Evaluating the Printability and Mechanical Properties of LFAM Regrind

A study conducted by SABIC and Local Motors identified potential for the reuse of scrap reinforced polymer from large-format additive manufacturing. As this method increases in popularity, sustainable practices for recycling excess materials is a burgeoning concern.

-

Next-Gen Horse Trailers to Be Built With Robotic 3D Printing

Double D Trailers is currently developing a prototype horse trailer that will be made with large-format additive manufacturing. The technology brings potential benefits for labor, weight and design features to this subset of recreational vehicles.