Henkel, Nexa3D Launch Ultrafast Photopolymer for Rapid Prototyping

The xPRO410 material for general purpose prototyping has a formulation based on Henkel’s Loctite PRO410 polymer and optimized for the Nexa3D’s NXE400 3D printer.

Share

Read Next

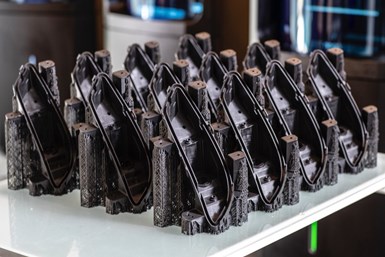

High accuracy parts printed with xPRO410.

Henkel and Nexa3D have collaborated on the launch of xPRO410, an ultrafast general-purpose material for rapid prototyping. Nexa3D, the maker of ultrafast stereolithography production 3D printers, and Henkel, a supplier of high-impact functional additive materials, have partnered to create this new class of photopolymers. According to the companies, it is a rigid photoplastic that prints extremely high-accuracy parts with exceptional surface finish. The formulation is based on Henkel’s Loctite PRO410 polymer and optimized for the Nexa3D’s NXE400 3D printer.

The company says this general-purpose material enables multiple daily design iterations and same day on-demand parts for small and large product enterprises. The rigid material is said to be well-suited for service bureaus seeking to upgrade their services to same day and next day fulfillment. It enables the fast and accurate printing of parts for a wide range of form, fit and function designs, and exceptional appearance prototypes. The xPRO410 can be printed continuously on the NXE400 at speeds of up to 8 L per hour, representing a 20X productivity gain. Parts printed with xPRO410 are said to achieve dimensional accuracy of within 0.2% after postcuring on the Nexa3D xCure system and can withstand temperature exposure of up to 70°C.

Henkel and Nexa3D are working together to apply circular economy principles into their material formulation and printing processes. Through the implementation of end-to-end validated workflows, both companies are measuring and improving to minimize process waste, reduce energy consumption per part and work with customers to reduce their overall carbon footprint.

Related Content

-

3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

-

Solving 3D Printing’s Hidden Problem: Vibration

Ulendo’s vibration compensation software can double the speed of FFF 3D printers while maintaining part quality, all without changing the machine’s hardware.

-

AM 101: Digital Light Synthesis (DLS)

Digital Light Synthesis (DLS) is the name for Carbon's resin-based 3D printing process. How it works and how it differs from stereolithography.