On Traffic Jams, Vehicle Size, Building EVs and more

From building electric vehicles—and training to do so—to considering traffic and its implication on drivers and vehicle size—there are plenty of considerations for people and their utilization of technology in the industry.

Share

Read Next

From building electric vehicles—and training to do so—to considering traffic and its implication on drivers and vehicle size—there are plenty of considerations for people and their utilization of technology in the industry.

Today On Automotive

- Fisker’s Manufacturing Strategy (& Foxconn Rising)

- Learning to Build EVs

- Opel’s Clever Engineering: EV Meets H2

- Nissan’s Traffic Jam Hunter

- Less Congestion = Smaller Vehicles

- Definition of “Serious”

- 2022 Mitsubishi Outlander SEL

///

Fisker’s Manufacturing Strategy (& Foxconn Rising)

Fisker Ocean will be built by Magna. (Image: Fisker)

While automotive OEMs still want to be perceived as “tech” companies or, at the very least, “consumer electronics companies,” oddly enough things are now going in the opposite direction, as well.

Think only of Google and its Waymo operation (yes, Waymo is using commercially available vehicles now, don’t forget about the cute little Google car of 2014 (its name: “Firefly”)).

And how often do you hear rumors about the Apple car?

Foxconn Rising. Which brings us to Foxconn, the long-time contract manufacturer for Apple.

While it has evident chops in building things like iPhones, seems like its electronics know-how will lend itself to the production of electric vehicles.

It has agreements with Geely, Byton, Stellantis, and Fisker.

The Fisker agreement officially announced last week is interesting.

It is for Fisker’s Project PEAR:

Personal Electric Automotive Revolution

Or more to the point: an EV that will have a starting price of less than $30,000 before incentives that will be manufactured in the U.S., then in other global locations. The model will be distributed in North America, Europe, China and India.

Why Foxconn for Fisker? Henrik Fisker, “In order to deliver on our promise of product breakthroughs from Project PEAR, we needed to rethink every aspect of product development, sourcing, and manufacturing. Our partnership with Foxconn enables us to deliver those industry firsts at a price point that truly opens up electric mobility to the mass market.”

Fisker is operating with an “asset-light” strategy.

That is, its first model, the Ocean, an all-electric SUV, will be produced exclusively by Magna.

Meaning that unlike other EV startups, Fisker is not building a factory.

Its focus seems to be on all aspects of product development, with the manufacturing engineering and tooling and production and the like being done by contract manufacturers—which makes Fisker like a consumer electronics company.

A Real Factory. As Foxconn isn’t an auto manufacturer, we wondered about what the factory might be like. Would this be a place were a series of modules come together like so many Lego blocks?

So we asked. And the Fisker spokesperson told us: “On the manufacturing side, we will still have to press/stamp/paint/weld etc., so whatever shape the factory takes, we will still be sending a car down a production line.”

Yes, a real car factory.

///

Learning to Build EVs

Learning about robotic welding for EVs. (Image: VW)

Speaking of manufacturing electric vehicles, while many of the processes are the same as building ICE-powered cars, there are some non-trivial issues, like working with exceedingly high-voltage batteries, which aren’t.

So at the Volkswagen assembly plant in Chattanooga, where the ID.4 will go into production next year, the in-house Volkswagen Academy has added EV technology to its vocational training curriculum.

EV Making Is Different. One of the areas that is key for producing EVs is welding. Aluminum welding, in particular.

The ID.4 battery case is made with aluminum, so they’ve added aluminum welding—manual and robotic—to the course work at the plant. Because the all-electric ID.4 will be added to the production at the plant.

The Chattanooga factory is where VW builds the Atlas, Atlas Cross Sport and Passat. It is not all-EVs.

Still, Ilker Subasi, Manager of Training and Development at the complex, said, “Everybody in the plant will have to go through a mandatory computer-based high voltage and electro-mobility awareness training.”

It’s good to know.

///

Opel’s Clever Engineering: EV Meets H2

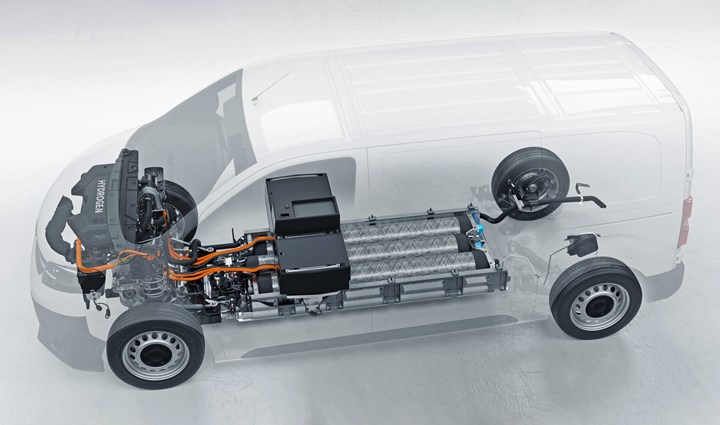

Hydrogen cylinders are put in place of the 75-kWh battery pack for the hydrogen version of the Opel Vivaro-e. (Image: Opel)

Opel has a light commercial vehicle named the Vivaro-e. It, of course, is an electric cargo carrier. It has up to 6.1 cubic meters of cargo capacity.

Opel has taken the Vivaro-e and transformed it into the Vivaro-e HYDROGEN.

Same two sliding doors. Same 6.1 cubic meters of capacity.

But some notable differences:

- The Vivaro-e with a 75-kWh lithium-ion battery pack has a range of 330 km (WLTP schedule—this is, after all, a European vehicle).

- The Vivaro-e HYDROGEN has a range of “more than 400 km.”

- The Vivaro-e can achieve a 80% charge on a 100-kW DC charger in 45 minutes.

- The Vivaro-e HYDROGEN can be fully refueled in about three minutes.

As Opel CEO Michael Lohscheller put it, “There is hardly another propulsion system in the world that offers the combination of zero emissions, long driving range and only three minutes refueling time.”

What makes this all the more interesting is that the Vivaro-e was engineered to be transformed to hydrogen power.

Swap Out. The main battery pack is removed and three 700-bar carbon fiber hydrogen tanks are put in its place.

The traction motor used for the electric version is used for the hydrogen version, so that stays put.

And the hydrogen vehicle is something of a plug-in hybrid: the 45-kW fuel cell is supplemented by a 10.5-kWh battery that is located under the front seats.

The battery is used for supplemental power, such as when starting from a stop or during acceleration. There is a plug so the battery can be recharged; the vehicle also has regenerative braking so energy can be harvested through that.

The vehicle can travel up to 50 km on the battery alone.

Rüsselsheim & Hydrogen. The Vivaro-e HYDROGEN will be built at the Opel plant Rüsselsheim by the Opel Special Vehicles operation. Deliveries to fleet customers are planned for Fall 2021.

Rüsselsheim, incidentally, is not only the home of Opel, but where the Stellantis “Competence Centre for Hydrogen and Fuel Cells” is located.

Opel (along with Abarth, Alfa Romeo, Chrysler, Dodge, Fiat, Fiat Professional, Jeep, Lancia, Ram, Maserati, Peugeot, Citroën, DS, and Vauxhall) is a Stallantis brand.

///

Nissan’s Traffic Jam Hunter

He made traffic jams easier to deal with, for Nissan ProPILOT users, at least. (Image: Nissan)

This is Tyler Szymkowski. He is now a human factors and ergonomics engineer at Nissan Technical Center North America in Farmington Hills, MI.

Before he became a Nissan engineer, he was an intern.

He spent three rotations as an intern there.

One of his intern jobs: Sitting in traffic jams.

Chasing Congestion. He was sort of like a tornado hunter: he would keep an eye on a traffic app on his phone, and when he saw a dark red line indicating gridlock, he took off to become part of it.

“Each day I would look to see if it was a ‘good’ traffic day and good for me meant bad traffic for most people,” he said.

He traveled the country in search of gridlock.

He sat in Los Angeles, Washington, Detroit, Pittsburgh, Baltimore and San Francisco.

This wasn’t a “Let’s have the intern do something silly.”

Rather, Nissan was enhancing its ProPILOT Assist hands-on driver assistance system.

In the original system, launched on the 2018 Nissan Rogue, the Intelligent Cruise Control system was capable of brining the vehicle to a full stop and then resuming forward movement when the traffic started moving—assuming that happened within three seconds.

Otherwise, the driver had to tap the accelerator pedal to get forward motion.

Thanks to Szymkowski, that hold time is now 30 seconds.

He spent a lot of time going nowhere to help his Nissan colleagues figure that out.

///

Less Congestion = Smaller Vehicles

Although the pandemic has mitigated some rush hour traffic, let’s face it: things will get back to normal(ish).

That is, according to a survey conducted by PwC, 75% of executives anticipate that by July 2021 “at least half of office employees” will be back in the office. The employees are less bullish, with 61% expecting to spend half their time back at their desks.

Still, more driving is becoming the norm.

Researchers from Washington State University (WSU) and the Brookings Institution surveyed people in the Seattle area over a six-year period and have determined that congestion pricing—charging tolls for driving during peak hours—can have a significant impact on not only when people drive, but what they drive.

The Size of Traffic. Apparently people buy bigger vehicles when commutes are more congested. The bigger vehicles are perceived to be not only more comfortable, but safer.

Explains Jia Yan, WSU economics professor and a co-author of a paper on the study appearing in Journal of Econometrics, “If the highways you are traveling on are very congested and you are sitting in a small car surrounded by many large SUVs, that may motivate you to purchase a larger car to protect yourself.”

Yan added, “If the congestion decreases, and drivers can easily travel on a free-flowing highway, that self-protection motivation drops.”

Appreciably.

The researchers estimate that nation-wide congestion pricing could lead to a decrease in market share of mid- to full-size SUVs by 8%.

The knock-on effects of that, they calculate, would be a 10% decline in the vehicle fatality rate and a savings of $25-billion in associated costs, as well as a 3% improvement in fuel efficiencies.

Of course, OEM margins would take a hit, too.

///

Definition of “Serious”

G70 Shooting Brake: Designed specifically for the Euro market by Genesis. (Image: Genesis)

Genesis announced on May 4 that it was expanding to the European market.

Eight days later it revealed the G70 Shooting Brake, a market-specific model. (You are not going to be able to buy one in the U.S.)

Understated quote: Dominique Boesch, Managing Director of Genesis Motor Europe, said, “We are delighted to reveal this bespoke product - tailored for our European customers - so soon after revealing news of our arrival into the region.”

The G70 Shooting Brake is based on the G70 sedan and has the same overall dimensions (184 inches long, 73 inches wide, 55 inches tall, a 111.6-inch wheelbase). However, given the station wagon style, the luggage space is 40% larger.

Genesis just might be the most serious company in the business.

///

2022 Mitsubishi Outlander SEL

Mitsubishi executes a superb crossover with the ‘22 Outlander. (Image: Mitsubishi Motors)

Perhaps the biggest problem that Mitsubishi Motors has is that it is, by and large, not by (i.e., you’re not going to find a Mitsubishi dealership nearby, as you will, say, a Ford store) and it is not large (the dealer body consists of 332 stores, about a tenth of those featuring a Blue Oval).

And while other brands like Toyota, Honda, Subaru and Nissan probably have a certain percentage of share-of-mind when one is musing about a new crossover, that share for Mitsubishi is probably on the order of “not much.”

Bet You Didn’t Know: The first Mitsubishi car, which was built by Mitsubishi Shipbuilding, the Model A, was launched in 1917. That’s 16 years before the first Toyota and 46 years before the first Honda.

It’s not for lack of experience that Mitsubishi’s share of the market is so miniscule.

Small fish? One of the things about Mitsubishi Motors that is worth knowing in the context of other vehicle manufacturers is that on the parent company’s website, when filtering companies that are part of it by industry, there are 24 categories, from “Banking & Securities” to “Travel, Recreation & Hotel.”

Then under “Transport Equipment” there are 35 search results, one of which is Mitsubishi Motors.

Let’s face it: when you’re the Ford Motor Company and there is a division named “Ford” and pretty much everything the company does is dedicated to transportation and mobility (there is a part of Ford, Spin, that offers city scooter services), things with tires is the focus.

Be that as it may. . . What has always struck me about Mitsubishi is that it makes some good vehicles that very few people know about. It also makes some that awkwardly styled so even if the underpinnings may be impressive, no one would really want to get in to find out (e.g., the current generation Mirage sedans—the only cars in the U.S. lineup—are not stylistically in the same league as their Japanese and Korean competitors).

This could be it. According to the official verbiage from the company, “The long-standing flagship of Mitsubishi Motors, Outlander is a crossover SUV that is loved by a wide range of customers in about 50 countries around the world.”

If that intense affection is related to sales, the U.S. isn’t exactly one of those markets.

But with the 2022 version of the three-row compact crossover, things could change.

Greatly.

“I-Fu-Do-Do.” That isn’t some juvenile phrase that I thought I’d put in here to see if you’re paying attention.

It is actually the product concept used to develop the look and feel of the vehicle.

It means authentic and majestic.

I’d call it fresh.

The styling is bold and contemporary. Especially the front end. The design theme for it is called “Dynamic Shield.” I’d call it “Optical Intensity,” as the treatment of the lamps is the dominant feature and executed in a way that is unlike what you ordinarily find. Now the trend seems to be to make the lights thin and constrained. The lenses are a key aspect of the overall look.

While there is a high beltline and character lines on the body side, there isn’t a whole lot that is distinctly different from other CUVs, and the same with the rear.

Inside it is really a well-executed environment.

On the one hand, there is the quilting of the seating and some of the trim pieces, which signifies if not full-on luxury, then at least a measurable cut above the norm.

On the other hand, the whole instrument panel—from the 12.3 digital gauge cluster to the central 9-inch infotainment display to HVAC vents that bisect the top and bottom halves of the IP surface—has an appearance that is clean and confident.

One of the things that I wince about is the third row. At least it readily folds to increase cargo space.

What moves it. It has a 181-hp, 2.5-liter I4 engine and an eight-speed CVT that has a sport mode that allows for faster “gear” changes.

The Outlander I had was equipped with S-AWC, an electrically controlled four-wheel drive system that features a hydraulic clutch and an electric motor in the center coupling to distribute torque to the front and rear as necessary.

Three is also a drive mode selector that makes adjustments based on driving conditions (e.g., Snow works to minimize wheel slip). You can probably just leave it in Normal unless you find yourself in snow or mud or gravel.

Find one. Odds are good—given the number of people who are in the market and the type of vehicle they’re looking at—a new compact crossover may be in your future. If so, this may be hard to find but worth giving it a search.

Related Content

8 Cool Parts From RAPID+TCT 2022: The Cool Parts Show #46

AM parts for applications from automotive to aircraft to furniture, in materials including ceramic, foam, metal and copper-coated polymer.

Read MoreDaimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

Read MoreMultimaterial 3D Printing Enables Solid State Batteries

By combining different 3D printing processes and materials in a single layer, Sakuu’s Kavian platform can produce batteries for electric vehicles and other applications with twice the energy density and greater safety than traditional lithium-ion solutions.

Read MoreDo Distributors Dream of Digital Inventory? Würth Additive Group Does

It’s more than a dream for Würth Additive Group and its parent company, in fact. Along with supplying additive equipment, the group is now developing solutions for sourcing 3D printed parts in a reliable, elastic digital inventory model.

Read MoreRead Next

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More

.jpg;width=70;height=70;mode=crop)