3MF Consortium Releases Beam Lattice Specification Extension

The software extension provides a solution for storing and transferring lattice-type geometry information.

Share

Read Next

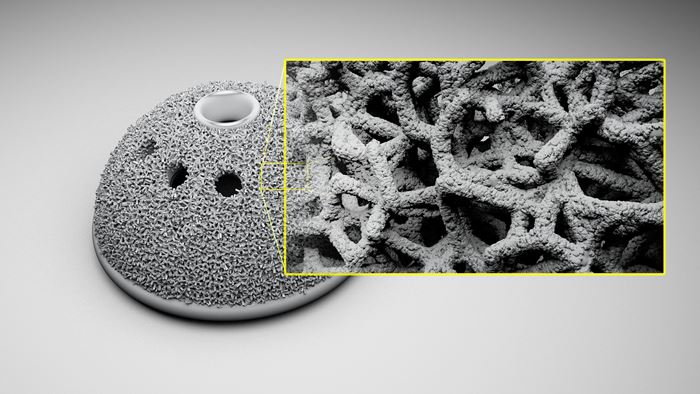

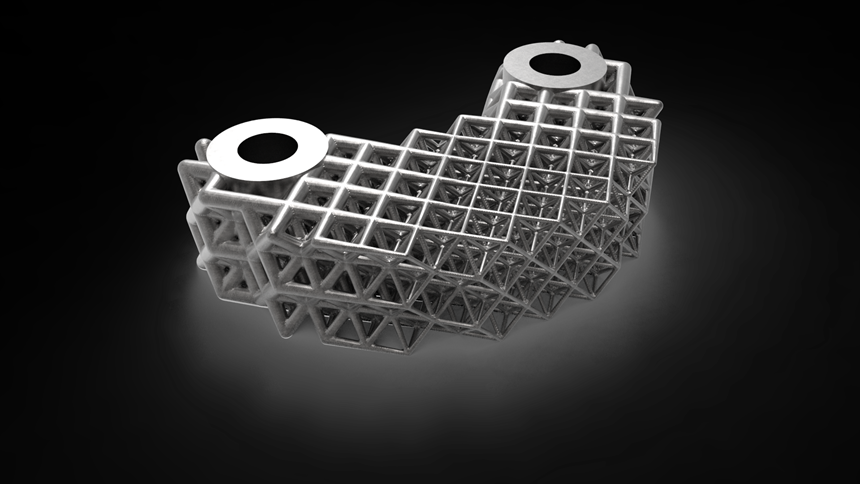

The 3MF Consortium has ratified and released a Beam Lattice Specification extension to its Core Specification. The extension stores and transfers lattice-type geometry information. By providing support for beam lattices, it solves interoperability issues and provides a solution to a problem that is not easily addressed in other file formats. Its benefits include improved design flexibility, lower material costs and reduced production time.

Designers and engineers can use the extension to design part interiors that were impossible to produce a few years ago. As the extension inherits all the features from the Core Specification, it retains build information, colors, materials and technology-specific characteristics like support structures in one file. The extension is available to download here.

The extension is designed to enrich the geometry notion of 3MF with beam lattice elements that can represent small-scale lattices as well as larger truss structures, both of which are inefficient for handling mesh representations, especially when the element count grows into large numbers.

This is the fourth specification extension, furthering 3MF’s goal of providing a universal specification that serves as the backbone of the additive manufacturing ecosystem, and enables companies to focus on innovation rather than basic interoperability issues. The consortium provides open source code free of charge to reduce the barrier to adoption.

Related Content

-

Aircraft Engine MRO: How Additive Manufacturing Plus Robotic Finishing Will Expand Capacity for Blade Repair

AM offers the chance to bring fast, automated processing to individualized, part-by-part restoration of turbomachinery. A cell developed by Acme Manufacturing and Optomec is able to automatically repair 85,000 unique aircraft engine blades per year.

-

Solving 3D Printing’s Hidden Problem: Vibration

Ulendo’s vibration compensation software can double the speed of FFF 3D printers while maintaining part quality, all without changing the machine’s hardware.

-

Taking the Leap into Additive Manufacturing

SolidCAM’s partnership with Desktop Metal, and its in-depth experience in combined metal 3D printing and CNC finishing, is aimed at making additive manufacturing accessible and profitable for job shops and other manufacturers.