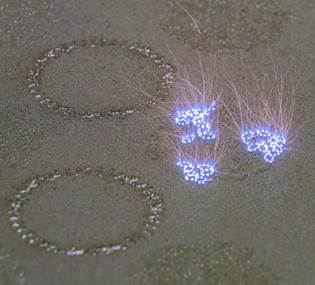

Variability in attributes of parts printed on different machines remains a major roadblock to certification and adoption of metal additive manufacturing technologies. Sources of these variability can occur both at the processing and materials level, which are not well understood. SLM Solutions will present a study of variability at the melt-pool level in different laser powder bed fusion systems using identical material and process parameters. Using machine-learning techniques, SLM Solutions will identify processing parameters that are potential major sources of variability in the melt pool, and map a “variability profile” for each individual machine system. The variability profile for each machine significantly reduce the amount of time and resource required to determine optimal processing parameters of the machines to fulfill specific part requirements.

Presenter:

Ji Ma, Ph.D.

Assistant Professor, University of Virginia

Ji Ma an assistant professor within the Department of Materials Science and Engineering. His research focuses on microstructural control and materials design of additively manufactured metallic alloys, patient-specific medical alloys and devices, and stimulus-response materials. He is the co-founder and president of Adallo, a medical devices startup.