3D Printing for Production at Scale

Additive manufacturing for production employs the use of 3D printing to make end-use functional components at production repeatability and scale. “3D printing” describes an entire group of part making processes that generally build components layer by layer using an ever-growing variety of materials. Additive manufacturing is often implemented as a bridge production solution for a new product before it moves to a more conventional method, but is increasingly being applied as the sole manufacturing method for full-scale production.

ESSENTIAL READING

VIEW ALLVideo: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

WatchCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

ListenThe AM Ecosystem, User Journeys and More from Formnext Forum Austin: AM Radio #43

Sessions and conversations at the first U.S. Formnext event highlighted the complete additive manufacturing ecosystem, sustainability, the importance of customer education, AM user journeys and much more.

ListenHow to Organize for Additive Production: AM Radio #42

Tim Simpson and Peter Zelinski discuss the next steps for succeeding with AM: After technical and process successes come the cultural, organizational and even costing considerations associated with this mode of manufacturing.

Listen5 Big Themes in Additive Manufacturing at Formnext Forum: Austin

Formnext Forum: Austin, a two-day event at the end of August focused on additive manufacturing for production, includes a conference exploring important ideas in AM related to supply chains, bridge production, enterprise transformation and more.

Read MoreA Framework for Qualifying Additively Manufactured Parts

A framework developed by The Barnes Global Advisors illustrates considerations and steps for qualifying additively manufactured parts, using an example familiar to those in AM: the 3D printed bottle opener.

Read MoreLatest Production News And Updates

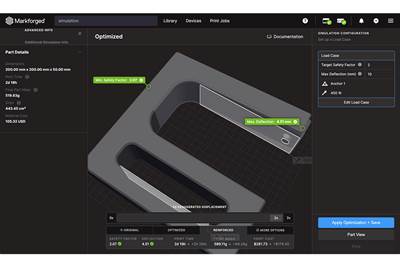

Markforged 3D Printing Simulation Software Validates Composite Part Strength

The virtual testing validates the strength of advanced composite parts and automatically optimizes print parameters to lower cost and speed production.

Read More3D Printing Helps Push the Boundaries for Green Energy

Partners in the European HyP3D project say they have reached a breakthrough in high-pressure hydrogen production through 3D printing.

Read MoreDyndrite Powers BCN3D’s High-Viscosity, Production-Oriented VLM System

The collaboration brings users high-performance, end-use resin part printing with GPU-powered automated production software.

Read MoreWestec Plastics Partners With Mantle to Speed Tooling Production

Using Mantle's technology, Westec says it can complete up to 70% of the job and have its toolmakers handle the specialized steps only humans can do.

Read MoreVelo3D Qualifies Aluminum Alloy to Support Formula 1 Customers

Aluminum alloy supports Formula 1 customers by enabling the production of parts requiring high thermal conductivity and durability, and is available to print in both 50 and 100 micron layers.

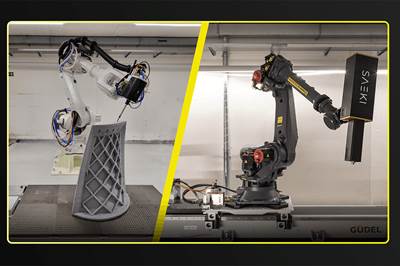

Read MoreSaeki Robots Manufacture Large Parts for Lights-Out Production

Saeki says it is building flexible factories of the future by leveraging digital manufacturing and robotics, providing an end-to-end automation solution in 24 hours with manufacturing large parts performed by robots.

Read MoreFeatured Posts

In "Hybrid" FIM Process, 3D Printing Complements Injection Molding

In a recent case study, Alpine Advanced Materials partnered with Nexa3D to produce 3D printed tooling for injection molded composites. Utilizing Nexa3D’s XiP desktop 3D printer and its Freeform Injection Molding process, Alpine was able to reduce prototype tooling production time and cost alike for its customers.

Read MoreVariable Resistance Valve Trim Achieves Lead Time Reduction Through AM: The Cool Parts Show #69

Baker Hughes is realizing shorter lead times and simplified manufacturing through powder bed fusion to produce valve trims previously assembled from many machined metal parts.

WatchThe Cold Spray Solution to the Casting, Forging Supply Chains

Startup HAMR Industries performs additive manufacturing work at Neighborhood 91 that provides an alternative to traditional casting and forging. Success so far has led to redefining the limits of its additive equipment.

Read MoreFeatured Media

What Is Neighborhood 91?

With its first building completely occupied, the N91 campus is on its way to becoming an end-to-end ecosystem for production additive manufacturing. Updates from the Pittsburgh initiative.

WatchVideo: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

WatchThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

WatchFAQ: Production

What is bridge production?

“Bridge production” refers to the initial, lower-quantity production of a new product or part that the manufacturer performs quickly. That is, production carried out now: before the tooling is produced, before the final process is engineered, before the part or product design is even finalized. It bridges the production gap between concept and creation.

Are 3D printing and additive manufacturing the same thing?

Some say yes and we say no! AM and 3D printing are overlapping terms but not synonyms. 3D printing is the operation at the heart of additive manufacturing, just as “turning” or “molding” might be the operation at the heart of a conventional manufacturing process.

In a nutshell, 3D printing is one step in an overall additive manufacturing workflow that also includes design, build preparation, postprocessing, business considerations and more.

Importantly, “3D printing” does not describe just one type of technology. Per ISO/ASTM, there are seven different “families” of 3D printing processes, and a growing number of material and machine options.

When is additive manufacturing the best production choice?

Additive manufacturing has been shown to be a good option in numerous production applications. These includes instances where:

- A product is designed with a complex geometric makeup, especially internally, that often consolidates multiple parts into one AM produced part.

- Low volumes are produced, typically for niche products, though the quantities appropriate for 3D printing continue to increase.

- Goods must be personalized or customizable.

- Items need to be manufactured locally.

- Investing in conventional equipment is a barrier.

What are the different types of additive manufacturing?

Additive manufacturing has been categorized by ASTM F2792 Standards into the 7 Families of Additive Manufacturing. They are:

- VAT photopolymerization

- Powder bed fusion (PBF)

- Binder jetting

- Material jetting

- Sheet lamination

- Material extrusion

- Directed energy deposition and hybrid manufacturing

Source: 3D Printing Processes

What do you need to be ready for additive manufacturing production?

1. Multiple materials

2. Multiple platforms

3. Location near customers

4. Postprocessing and finishing capability

5. Open machine capacity

6. Agility

Source: What Does Additive Manufacturing Readiness Look Like?

How does additive manufacturing benefit serial production?

Unlike a typical serial production job where parts are made identically every time, additive as the production technology allow the customer to continue to iterate even as products are put into testing and into the market.

As described in this article, a production run of bezels for automotive sensors, for instance, saw the same number of design iterations within a much smaller quantity.

“Within 500 parts that we printed, they made three changes,” says Kyle Harvey, business unit manager for additive manufacturing at Extol. This is not just additive manufacturing taking over production; it is a different kind of production all together.