Overcoming the Challenges of Copper

A research organization in Germany is developing a laser beam source that operates with a green light, enabling selective laser melting of a copper alloy.

Additively manufacturing parts in copper opens new doors for engineers creating novel geometries for thermal management systems. Design freedom enables the implementation of nonlinear and tapered geometries in extended structures like fins, vane blades, capillary wicking structures, heat pipes, and conformal internal passages or conformal induction coils.

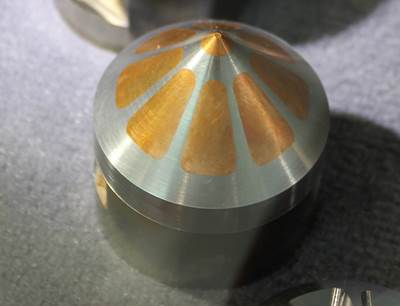

Usually made of wire or tube material, 3D-printed induction coils can now be designed and configured online on the Protiq web portal, where customers can upload and configure 3D models, Managing Director Ralf Gärtner explained at Formnext 2017 in Frankfurt, Germany. “There are not many companies that can additively manufacture copper, but we have developed a highly conductive copper alloy (91.2 percent copper with electrical conductivity in the surface layer ranging from 50 to 52 Ms/m and in the core from 30 to 32 Ms/m), which can be printed via selective laser melting.”

Protiq also offers selective laser melting of the thermal curable copper alloy CuNi2SiCr, which—similar to chromium zirconium copper (copper C18150) developed and used for direct metal laser sintering (DMLS) by Stratasys—features excellent electrical and thermal conductivity.

Pure copper would be the most attractive option for end users, though, as it is more electrically and thermally conductive than copper alloys. However, depending on surface properties, pure copper reflects most of the laser radiation in conventionally used wavelengths of 1 micron.

According to Daniel Heussen, research fellow in the Rapid Manufacturing group at the Fraunhofer Institute for Laser Technology (ILT) in Aachen, Germany, only a small portion of the laser energy is deposited in the material and is available for the melting process. “The reflected radiation can also damage the components of the AM system,” he explained. “In addition, the absorptivity of the material for the infrared light rises rapidly as the material transitions from a solid to liquid state, thus triggering an unstable and intermittent remelting process.”

Therefore, the ILT is developing a laser beam source that operates with green rather than infrared light. Initial process videos were on show at Formnext. “Using green laser light with a wavelength of 515 nm, the absorptivity of pure copper is much higher,” Heussen explained. “This means that less laser power output is needed for a stable process. Furthermore, the laser beam can be focused more precisely, allowing it to manufacture far more delicate components using the new SLM process. We are hoping for more homogeneous meltpool dynamics so that we can build components with high material density and achieve other positive effects, such as a higher detail resolution.”

With no such “green” laser source on the market meeting the boundary conditions of the SLM process, the department for laser beam source development at Fraunhofer ILT is building its own in a project they call “SLM in green.” The aim is to create a high-quality laser for single-mode operation that functions with a maximum output of 400 watts in continuous service (cw) with green wavelength (515 nm). Heussen expects an “SLM in green” laboratory setup to be ready by the end of 2017. Thereafter, the Fraunhofer ILT will further develop its processes as part of a research project.

“The primary future goal is to create a reliable process with which industrial users can 3D print complex geometries of pure copper with hollow structures and undercuts,” Heussen said. The process can be used for highly efficient heat exchangers and heat sinks or for the production of delicate, complex electrical components in small batches. “Inductors for inductive heat treatment in industrial production are excellent showcases for additive manufacturing. They are mostly produced in small batches with a high level of complexity and a wide range of different variants.”

In the field of jewelry design, for example, “SLM in green” could offer a more efficient and reproducible process for manufacturing complex structures than conventional techniques. The researchers are hoping for a notably higher detail resolution as well as greater cost efficiency in production compared to other additive methods such as electron beam melting (EBM). The green laser should be suitable not just for copper, but also nonferrous and precious metals in the jewelry industry. “However, before we achieve that, we still need to overcome a few hurdles in process and system development and gain a deeper process understanding for the use of the new wavelength,” Heussen said. “This is currently the goal of the publicly funded project, which will run until mid-2019.”

Related Content

AM 101: What is Ultrasonic Additive Manufacturing?

Going from additive to subtractive can be simple with Ultrasonic Additive Manufacturing (UAM). What is it and how does it work? Learn the basics in this 101 post.

Read MoreAM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

Read MoreWhat is Powder Bed Fusion 3D Printing?

Whether in metal or polymer, with a laser or an electron beam, powder bed fusion (PBF) is one of the most widely used 3D printing techniques.

Read More3D Printing Molds With Metal Paste: The Mantle Process Explained (Video)

Metal paste is the starting point for a process using 3D printing, CNC shaping and sintering to deliver precise H13 or P20 steel tooling for plastics injection molding. Peter Zelinski talks through the steps of the process in this video filmed with Mantle equipment.

Read MoreRead Next

Hermle Combines Metal Powder Application Process with Five-Axis Machining

Hermle integrated its MPA technology, a process where metal powder is applied by kinetic compacting to build completely sealed materials, in a Hermle five-axis machining center to create parts with highly complex inner geometries.

Read MoreVideo: The Case for Hybrid Manufacturing in Moldmaking

Instead of relying on EDM to machine features recessed deep into the part, machine those features while 3D printing progresses, finishing them before they become hard to reach.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More