Here Is What a Four-Laser Machine Can Do—and Here Is the Hardware Used to Do It

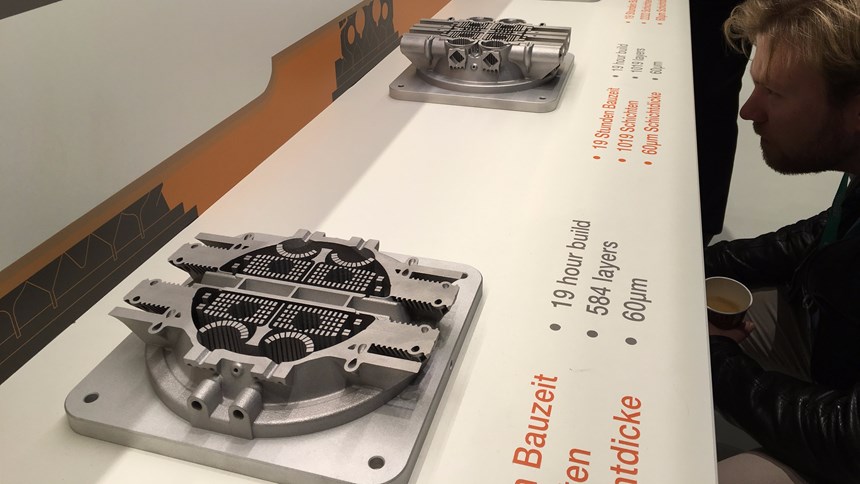

One laser gets you this far. Two lasers get you this much farther. These productivity comparisons with a four-laser machine also show the cooling geometry that brings four lasers together.

The enabling technology for Renishaw’s newest additive manufacturing machine is additive manufacturing.

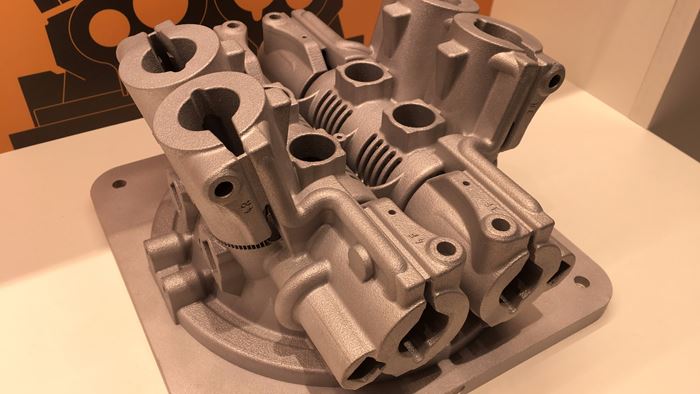

At Formnext, the company introduced its RenAM 500Q selective laser melting machine, which applies four 500-Watt lasers within a compact machine offering a build volume of 250 by 250 by 350 mm. Concentrating four lasers within the tight space brings the lasers close to one another. Heat is a concern, and it was a potential impediment to the design. The solution to this challenge that Renishaw engineers found involves a laser galvo mount enhanced for cooling via a large internal surface area resulting from a complex internal design that was realized through AM.

The company’s display of the galvo mount on the show floor therefore communicated two important messages at once. Why additive? In this case, the reason was internal features that couldn’t be produced practically in any other way. And why four lasers? The reason is the increased productivity that comes from being able to melt more metal at once than a single beam would allow. Showing how far the machine can get in a given period using one laser, two lasers and four illustrates the productivity gain at each step. Meanwhile, the incomplete parts left by the slower processes provide a view into the otherwise hidden geometry enabling the compact machine.