Capability to 3D Print H13 Delivers Robust Tooling

Direct metal laser sintering H13 material plays a big role in how this company has differentiated itself from the competition.

Share

Read Next

Tell me a little bit about Next Chapter Manufacturing?

Jason Murphy, President, and CEO: The company’s mission is to take a standard tried-and-true additive process, like direct metal laser sintering (DMLS), and use it innovatively to provide solutions to moldmakers and molders. When we launched the company, we used DMLS to retrofit and improve existing tooling. However, with my background in molding (certified Master Molder) and moldmaking, we have since expanded our focus to include the design side of tooling (molds, die-cast dies, end of arm tooling, fixtures and automation components) to improve speed, reduce cycle times and eliminate common molding defects (warp, burning, gas trap), primarily in the automotive and medical industries. Our specialty is high-volume, high-cavitation tooling or high-wear applications involving highly-engineered resins for which the industry is not 3D printing parts for to date. We build high-wear tools and offer a million shot guarantee. We accomplish this by partnering with mold shops to solve molders’ production issues and maximize productivity (OEE, scrap, downtime). This year we are expanding our focus again to scale operations and move into the consumer, electronics and industrial markets for tooling and molding.

It seems to me that mold material plays a big role in how you’ve differentiated the company from the competition. Explain.

Murphy: To successfully work in mold manufacturing, you must speak the toolmaker's language. For example, H13 has been the standard for building robust molds, but that material did not exist within the additive material spectrum until recently. Standard offerings were not traditional grades of tool steel, which created additional barriers for moldmakers to adopt 3D-printed tooling into their moldmaking process. Previously, additive metals were held to one or two grades of steel for which additive machine builders developed machine parameters. As a tooling company and not a 3D-printing service provider, our focus is on providing the optimal tooling solution, which is dependent upon the right materials to produce tooling capable of high-volume and high-wear applications. Since tooling components is not the primary market machine builders tailor to, there has not been as much tool steel materials development compared to other markets, like aerospace.

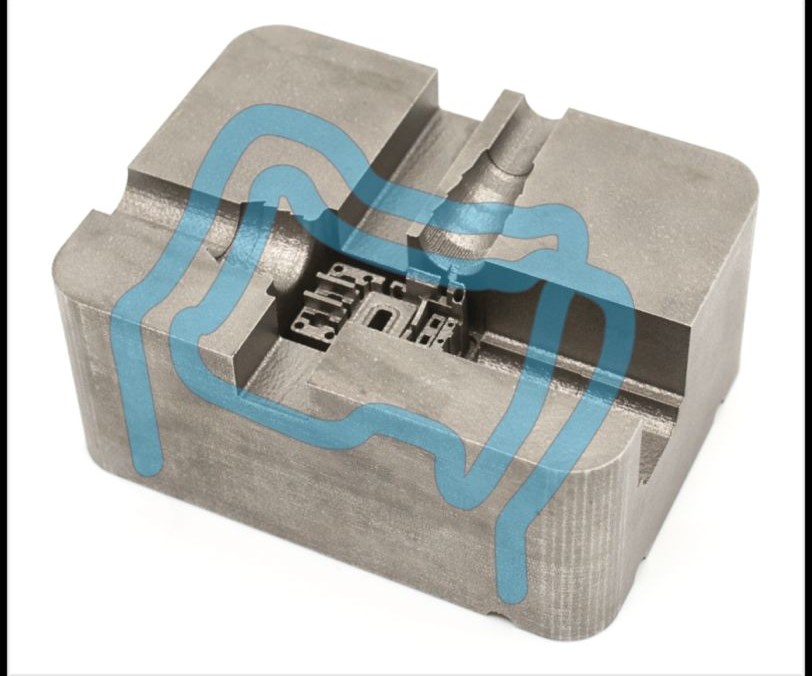

The DMLS process has been around for decades and produces very complex geometries and cooling channels while building near finish stock conditions that need minimal machining to achieve required tolerances and finishes. Our specialty is H13 in DMLS, where others use maraging steel. We believe this gives us a leg up because we’ve experienced H13 outperforming maraging steel by 20 to 25 percent, which aligns with the demand from moldmakers and molders to get the most out of their tooling investment.

We decided to partner with Farsoon Technologies because its system is open, which means we can develop specific processes that enable us to print H13 and other tool steels efficiently. This open parameter system also enables us to do test builds and refine our process to improve robustness and speed further. The technology of the Farsoon machine gives designers a significant amount of additional freedom to provide the most efficient designs for additive manufacturing, which other machines do not offer. However, we do remain technology agnostic, as we know the additive world is constantly evolving, delivering new, improved and different processes and materials. Our goal is to find the best technology on the market that suits the solutions we are looking to provide our customers and then integrate that technology into our workflow — from front end design and analytics to postprocessing.

Speaking of materials, we are also emulating venting in the steel and using DMLS to make the part porous to allow venting. Venting is just as important as cooling, so being able to add vents where needed, not “where possible”, is critical to providing the highest performance molds in the industry. This is a very new development that we are currently optimizing, so it is not yet commercially available.

You mention that your way of doing things is a “departure from traditional tools.” Explain.

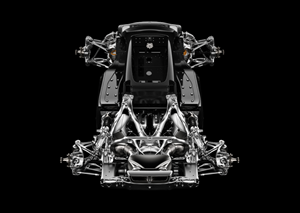

Murphy: Additive manufacturing (AM) allows us to think differently about what a mold needs to be. Molds don’t need to look round and square or incorporate typical lifters, locks, pins, bushings, parting lines anymore. We don’t need a mold to be a massive block of steel. We just need it to support the load it can do under pressure. Here is where generative design comes into play, as it considers all of the dynamics and forces that the mold will experience during the process and then provides hundreds of solutions based on any number of parameters. All of this helps to yield the most efficient tooling possible.

For example, we apply shot tonnage and all the forces the slides and moving components experience, and then the generative design software goes to work and optimizes it for 3D printing. Basically, the mass of an A or A, B plate is somewhere around 50 percent of what it would be. So, although AM is a slow process, the generative design allows us to build the tool in half the time because we have half the mass. Incorporating generative design into the moldmaking workflow allows us to arrive at the solution quicker and optimizes the additive process to be competitive with current mold manufacturing methods.

You say that although the process used may not be all that innovative, it’s more about how you use technology to bring customers innovative solutions. Give an example.

Murphy: We had a customer who was having trouble with mold cylinders, which nowadays are extruded aluminum, as they were running a high-temperature material in a high-temperature mold, which transfers heat into the cylinders, causing the switches to fail. Our solution was to create a cooling plate that flowed between all of the mounting holes that created a barrier between the cylinder and the mold. It had nothing to do with conformal cooling inside the mold or touching plastic, but it’s a solution that eliminated their downtime. By considering the challenges molders and moldmakers face in production every day and removing the limits of design and manufacturing, we can quickly get to the right solutions to “never talk about this problem again.”

Where do you see growth within the company in the next five years?

Murphy: We see standardized customization. By that, I mean standardization of mold components. For example, our conformally-cooled sprue bushings offered through PCS Company that reduce design time. We also see a focus on rethinking the most mundane mold components and design them additively for a customer’s specific application, which plays nicely into our customers’ demands for insert consistency across their global supply chain.

Related Content

What Does Additive Manufacturing Readiness Look Like?

The promise of distributed manufacturing is alluring, but to get there AM first needs to master scale production. GKN Additive’s Michigan facility illustrates what the journey might look like.

Read More3D Printed Cold Plate for an Electric Race Car: The Cool Parts Show #51

An unconventional lattice design and biomimicry are key to the performance of this fluid-cooled heat exchanger for a battery-powered race car.

Read MoreHow GM Is Investing in Additive and EVs

People within the automaker aren’t just working with additive, they are actively promoting it to their colleagues throughout the organization.

Read MoreDivergent Technologies Eyes High-Volume, Optimized Automotive Production Through Additive

While some automotive OEMs are using additive here and there, Divergent Technologies is basing its vehicles on 3D printed structures.

Read MoreRead Next

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More