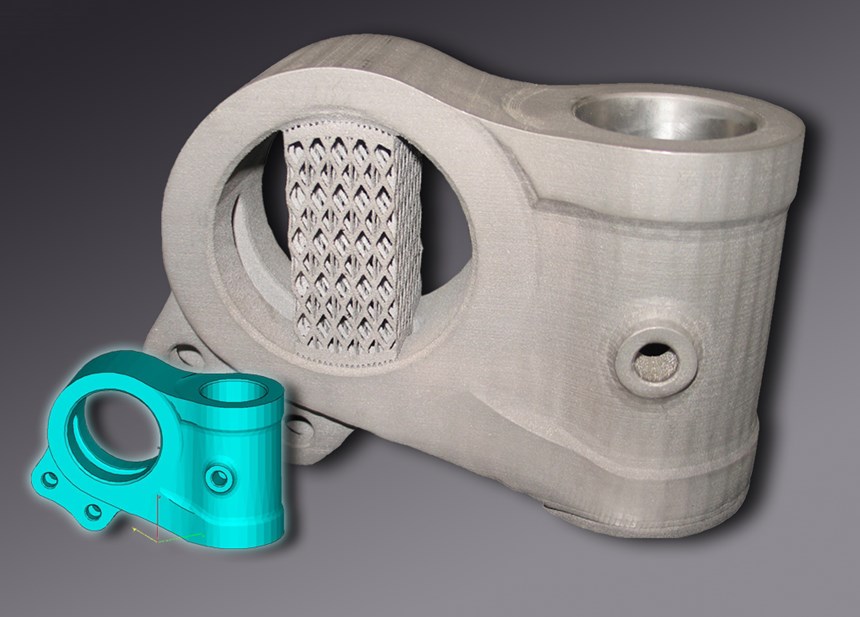

Within the additive manufacturing (AM) space, there’s a model for the evolution of design thinking that goes something like this: You might start with AM by 3D printing a part design you’re already making, which may be an easy win but doesn’t provide any real advantage. You might then improve the part—consolidate an assembly, reduce weight, etc.—taking advantage of some of the inherent benefits made possible by 3D printing. But the end of the model is to implement design for additive manufacturing (DFAM) from the very beginning, utilizing tools like topology optimization to create parts that couldn’t be made any other way. This is the ultimate goal: to make the best parts by designing them to make the best use of the technology.

In some ways, this proposed evolution of design thinking very closely mirrors what is happening in another area of AM: materials. I recently talked with some representatives of Carpenter Technology, a company that has been providing metals for manufacturing in forms including ingots, wire and powder since 1889. Today, its product mix includes metal powders and wire engineered for additive manufacturing, and Carpenter’s role has expanded beyond material supplier into a solutions provider.

"We want to build the correlation from powder to part, or wire to part.”

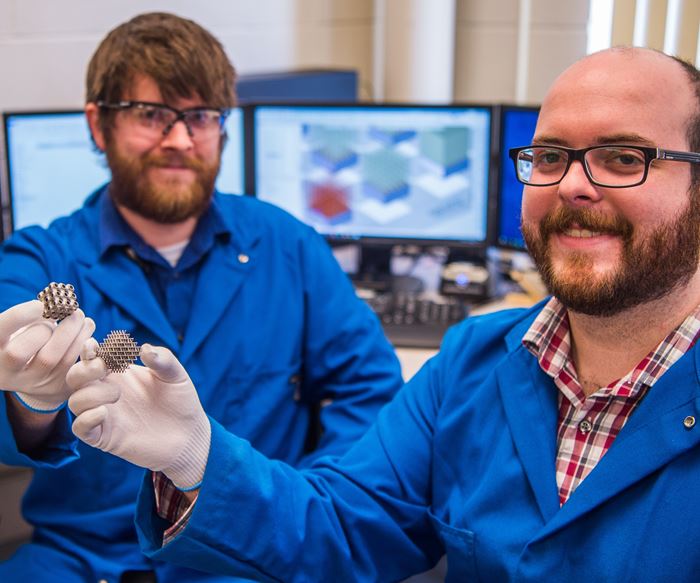

"We want to build the correlation from powder to part, or wire to part, and be an end-to-end player in this space," says Mike Murtagh, chief technology officer. Carpenter is moving toward this goal with its acquisition of CalRam in February 2018. CalRam is a Camarillo, California-based parts producer specializing in metal powder-based AM—specifically electron beam melting (EBM) and selective laser melting (SLM). The company has been in business since 2005, making parts primarily for the aerospace and defense industries. CalRam continues to serve these customers and still largely operates as a stand-alone manufacturer.

But the benefits to this acquisition are twofold. First, a close relationship with a production house gives Carpenter insight into additive processes and how materials behave inside specific machines with given parameters, and offers more direct access to customers and their challenges. "CalRam gives us the ability now not only on an R&D scale, but on a production scale, to better understand how materials ultimately translate into actual parts for customers," Murtagh says. "That perspective gives us a broader end-to-end solutions capability."

Secondly, CalRam and its customers benefit from Carpenter's vast materials knowledge and capacity to provide not just feedstock for additive manufacturing today, but also the next generation of AM materials. More on that in a moment.

Working with the Known

If the use and development of 3D printing materials is following that same three-stage trajectory as design thinking, then today manufacturers are largely in the first stage, relying on known alloys that can be applied for additive manufacturing. In the near term, therefore, these users need to understand how to optimize the AM processing of these existing materials.

“Today, there are about 5 to 10 alloys that we see being ordered 90 percent of the time,” says Will Herbert, director of corporate development for Carpenter Technology. These materials are the obvious choices because they fit AM processes, and also fall within specifications required for established additive machines. In other words, the alloys are familiar from the cast-wrought world, are compatible with 3D printing and known to be effective.

One reason for the limited number of alloys used in AM today has to do with final part properties. “When you’re forging, you work the material and can confer additional properties to the alloy, such as strength or fatigue resistance for example,” Herbert says. In the 3D printing process, where the material is formed simultaneously with part geometry, “We’ve been fairly limited in the universe of alloys because we have to select metals that you can strengthen without putting in this additional energy after the process.”

Yet despite their small number, even these existing alloys are still not perfectly understood. “A lot of the materials that have originally been utilized for additive manufacturing are really based on historical knowledge in areas like cast-wrought technology,” Murtagh says. “We’ve translated those directly to additive manufacturing, but I don’t think those materials have necessarily been tailored accordingly to the new technology. They’ve kind of been force-fit to some degree, because that’s what we know today.”

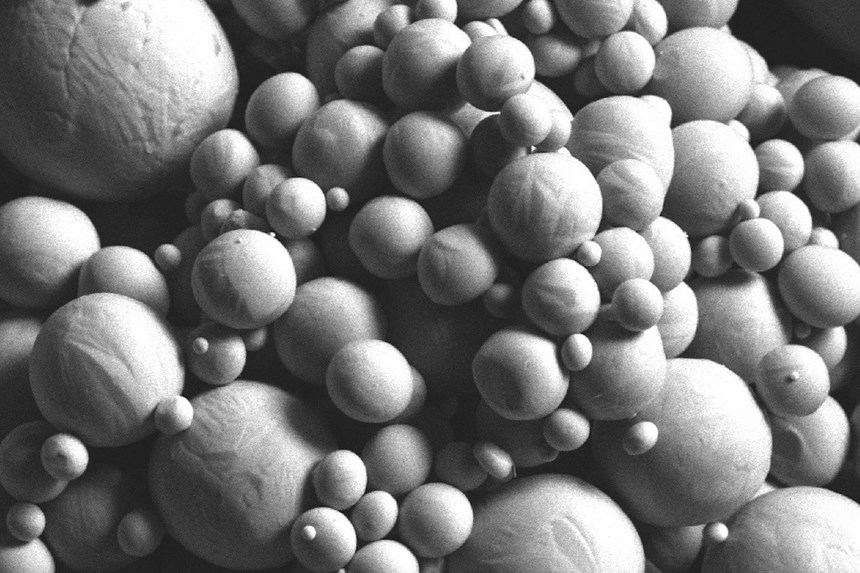

In its own AM materials research and through collaboration with CalRam, Carpenter is exploring how metal powder properties translate to the final component, and how factors such as particle size, shape and distribution affect the build with the materials (and machines) in use today.

This research is already expanding material options for metal 3D printing by encouraging a revisiting of what Herbert calls “back catalog” alloys—materials that are difficult to forge as large billets or to investment cast, for example, but may be good candidates for laser sintering or another AM process.

“When you wrought process these materials, the material composition can change very widely from the center of the billet to the outside,” Herbert says. “You can mitigate these types of segregation issues when you start with a powder, and your particle size is on the order of 30 microns, and your freezing rates can be very high. Suddenly we have all these ‘new’ alloys we can try out in [the additive] process.”

Update and Innovate

But beyond exploring its existing catalog with fresh eyes, Carpenter is also beginning to optimize materials specifically for additive. This allows for material that, while it still meets the specifications needed for additive machines, offers the benefits of being at least somewhat customized to the 3D printing process.

“In the medium term we can continue to take existing alloys within the industry standard specifications and tweak them, finding a way to optimize the chemistry, the particle shape and size, in order to deliver additional benefits,” Herbert says. “Again, you’re staying within a written specification; you don’t have to reinvent the wheel.”

The company’s recently launched CarTech Puris 5+ titanium alloy is an example of this sort of tweaking. This material grew out of the difficulty that CalRam (before its acquisition) was experiencing in 3D printing with Grade 5 titanium alloy (Ti-6Al-4V), says Eric Bono, manager of Carpenter Technology’s Additive Manufacturing Group. “They could not meet required mechanical properties with adequate ductility, and they came to us to solve the problem," he explains.

While Ti-6Al-4V is widely used, Bono says, the material itself has some issues when paired with AM. Namely, oxygen. Per ASTM International standards, Grade 5 titanium can contain no more than 0.2 percent oxygen. However, each time titanium powder is used and recycled, the oxygen content increases. This is why manufacturers commonly mix new powder into recycled batches: to keep the oxygen content within the allowable parameters. Standard Grade 5 titanium powder could not be used in critical applications until the oxygen content reached approximately 0.17 percent, which didn’t leave much leeway for recycling before hitting the 0.2 percent limit.

CalRam’s application challenged Carpenter to come up with a way to reduce the amount of oxygen. A material with lower oxygen would facilitate more recycling, reduce overall cost, and provide a better guarantee of part quality. But it wasn’t just a simple matter of reducing the oxygen content.

“The problem is that low oxygen also results in low strength,” Bono says, explaining that oxygen in dilute amounts is an important strengthening agent in titanium. With the standard Grade 5 titanium, 0.17 percent oxygen was necessary in order to also hit strength requirements for critical applications in high-performance markets such as aerospace, defense and energy.

Following on-site observation and analysis of data from CalRam, Carpenter’s technical team modified the alloy’s chemistry to create a metal powder that was still within Grade 5 specification, but with some key changes to better support additive manufacturing. “We were able to give them very low oxygen by tightly controlling several other strengthening elements,” Bono says.

"We solved one customer's problem, but it's really indicative of a problem across the entire industry."

The resulting material more than met the strength requirements of Grade 5 titanium. In fact, in testing CarTech Puris 5+ alloy consistently exceeded Grade 5 strength requirements by 20 percent. The virgin powder has an oxygen content of 0.13 percent, providing more headway for recycling and reuse, while also reducing the burden of testing and the risk in the final part. Furthermore, the new composition enabled CalRam to meet both the strength and ductility requirements of the application.

"Our ability to improve the alloy ultimately drove improvements in their process," Murtagh says, referencing lower rejection rates and increased part strength achieved through CalRam's use of CarTech Puris 5+. But it's not just CalRam that's benefiting from the new material.

"It has since become our most popular titanium alloy," Bono says. "We solved one customer's problem, but it's really indicative of a problem across the entire industry."

Customized materials like this could be a major boon to manufacturers in the middle term. But in the long term, AM materials development will mean going back to the drawing board and creating new powders that are actually optimized for additive applications and systems from the beginning to bring the best results. Carpenter plans to continue building technical knowledge about AM materials, parts, design and postprocessing through its work with CalRam and ongoing research at a newly commissioned AM R&D lab in its Reading, Pennsylvania, facility. A broader emerging technology center will be established within the next few years.

“I think we’re just scratching the surface in terms of new material development,” Murtagh says. “The more we understand about the actual printing technologies and the design capabilities of additive, the more we can work on the front end to tailor materials for throughput, speed, repeatability and the properties you want in the final part.”

Related Content

3D Systems’ VSP Bolus Optimizes Radiotherapy Targeting

The system is designed to enable the creation of a more personalized bolus made from a soft material that contours to the patient’s anatomy, enabling a more efficacious treatment and a more comfortable experience.

Read More8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples.

Read MoreNMPA Certifies Farsoon 3D Printed Tantalum Interspinal Fusion Cage

The company says the additively manufactured implants can be fully customized according to patients’ conditions, and the trabecular microstructure can achieve a high porosity of 68-78% to promote bone tissue and vessel fusion.

Read MoreWasp Polymer, Ceramic 3D Printers for Customized Serial Production

Formnext 2022: Italy-based Wasp offers 3D printing options for sustainable, customized serial production with polymers and ceramics.

Read MoreRead Next

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More

.jpg;width=70;height=70;mode=crop)