3D Printing with Renewable Materials, Frugally Applied (Video #1)

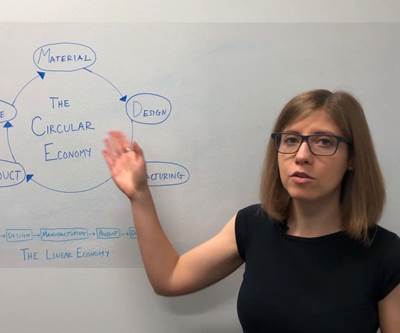

Part of our 3D Printing and the Circular Economy series, this video explores the ways that AM supports more sustainable material choices.

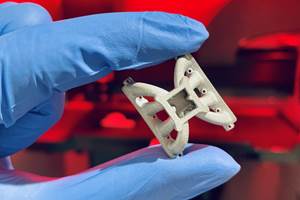

Adopting additive manufacturing (AM) often means reconsidering the materials that a manufacturer considers appropriate to the application. In some cases this transition offers clear benefits; a part that might been a poor fit for titanium because of the machining difficulty might now be 3D printed easily from this metal. On the other hand, the pivot to AM can introduce challenges, such as when there is not a one-to-one equivalent for the material used conventionally. Manufacturers can use the transition as an opportunity to investigate new material options that may be more sustainable than conventional feedstock, such as plastic filaments made from plants or metal powders made from recycled scrap.

Making the switch to AM also provides other inherent material benefits. 3D printing makes it possible to place material conservatively, only where it is needed — and this material frugality avoids waste and frequently results in lighter weight, more efficient parts. The video below describes the more sustainable material options and strategies available to manufacturers via 3D printing. It is part of our series on 3D Printing and the Circular Economy — join us on social media using the hashtag #CircularEconomyWeek all week long, October 12-16.

Resources and Related Links

- Videos in this series: What Is the Circular Economy? | Materials | Design | Manufacturing | Product | End-of-Life

- Why “Recycled” Doesn’t Mean Inferior for 3D Printing Filament

- Biopolymers from Plant Sources

- Sourcing 3D Printing Feedstock from Industrial and Post-Consumer Waste

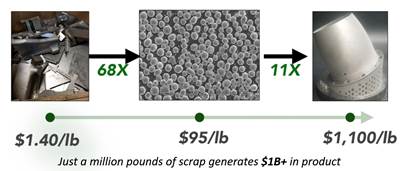

- Turning Metal Scrap into Additive Manufacturing Powder

- Recapturing Material from 3D Printed Furniture, Shoes

Transcript

welcome to our video series on 3d printing and the circular economy. In this video, we'll be talking about materials and how to choose and use them sustainably.

When a manufacturer adopts 3D printing, that's often an opportunity to rethink the kinds of materials that they're using to make their products. That also means it's a great chance to start looking at sustainable materials.

The key thing to keep in mind is the difference between renewal and nonrenewable resources. A nonrenewable resource would be something like petroleum which is used as the basis for a lot of different plastics. But it's a fossil fuel and once we use up our supply, there won't be any more left. It won't be able to replenish itself. A renewable resource would be something like corn or soy which can be used as the basis for plastics like PLA. If you need more feedstock, you can plant more corn.

But also consider materials that come from recycled sources like scrap metal, plastic bottles, used fishing nets. There are a lot of different companies working on this right now, and the options are growing day by day. Of course, it's not just the material that you choose, it's also the way that you use it, and you want to try to apply it frugally. We know that 3D printing is really good for this — putting material exactly where it's needed no more, no less.

Finally, think about limiting the variety of different materials that are used in any given assembly or product. If you're able to print a couple of different pieces together and consolidate an assembly that reduces the use of fasteners; it also makes it easier to manufacture. And if you're thinking ahead to what's going to happen to this product at the end of its lifecycle, it's going to be much easier to recapture that material and recycle it into something else if you're only using one or two easily separated materials.

So in summary, choose your material wisely, apply it frugally, and limit the variety that you're using in any given assembly or product. Learn more at gbm.media/CircularAM and AdditiveManufacturing.Media. Thanks for watching.

Related Content

Incus Successfully Tests Lithography-Based Metal Manufacturing for Lunar Environment

The project aim was to develop a sustainable process that uses lunar resources and recycled scrap metals (eventually contaminated by lunar dust) to produce spare parts on-site which could help and enhance human settlement on the moon.

Read MoreIperionX Developing 100% Recycled, Low-Carbon Titanium Metal Facility

The company’s titanium demonstration facility will be a titanium metal operation using 100% recycled titanium metal scrap as raw material feedstock in the U.S.

Read MoreHow Hybrid Tooling — Part 3D Printed, Part Metal Shell — Accelerates Product Development and Sustainability for PepsiCo

The consumer products giant used to wait weeks and spend thousands on each iteration of a prototype blow mold. Now, new blow molds are available in days and cost just a few hundred dollars.

Read MoreSculpteo Offers RE-cycleo 3D Printed Part Recycling Program

The program offers recycling services to Sculpteo clients not only for the clients’ obsolete parts but also for production scrap.

Read MoreRead Next

3D Printing Helps Close the Loop for Armor’s Circular Economy

Manufacturing 3D printing filament was first a way for Armor to recycle its own reclaimed plastic waste. But now, this business unit is helping to close the loop on sustainability for plastic 3D printed products.

Read MoreWhat Is the Circular Economy, and How Can 3D Printing Help? (Video)

What does it mean to be sustainable, to manufacture in a circular economy? And where does 3D printing fit? These questions and more answered in this video, the first of our 3D Printing and the Circular Economy series.

Read MoreIs Recycled Metal Scrap the Future Feedstock of Choice for Metal 3D Printing?

MolyWorks is future-proofing the circular economy for metals with small-footprint atomization technology that converts metal scrap into additive manufacturing powder on the spot. But that's not the end of the story.

Read More

.jpg;width=70;height=70;mode=crop)