Articles

The Softer Side of Robots: Automating Additive Manufacturing

Robotic applications are expanding in additive manufacturing thanks to rubber and silicone-based systems that can easily adapt to parts of varying sizes and shapes without reprogramming.

Read MoreUltiMaker Targets Light Industrial Applications With 3D Printer Designed for the Factory Floor

The company’s Factor 4 3D printer introduced this week is designed to complement conventional manufacturing equipment including CNC machining and automation.

Read MoreQ.ANT’s Compact Quantum Sensor Analyzes Particles for Improved Quality Control in Additive Manufacturing, and More News of Note

Replique announces public launch of 3D Printing Material Hub |APSX and Nexa3D integrate technologies to advance freeform injection molding.

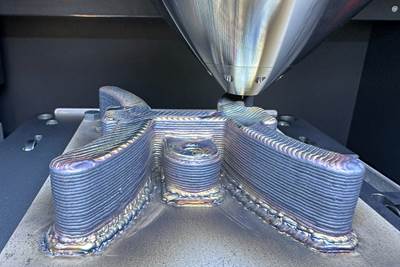

Read MoreHow Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.

Read MoreSouthern Indiana’s Thriving AM Part Producer — What I Saw at Innovative 3D Manufacturing: AM Radio #49

Recorded just after the visit to the laser powder bed fusion contract manufacturer, here is a conversation exploring observations and impressions of this company and its metal 3D printing work.

ListenPush-Button DED System Aims for Machine Shop Workflow in Metal AM

Meltio M600 metal 3D printer employs probing, quick-change workholding and wire material stock to permit production in coordination with CNC machines.

Read MoreMultimaterial, Self-Sensing, 3D Printed Scoliosis Braces

Startup Fited and Brightlands Materials Center have developed a lighter weight, thinner CFRP corrective brace, including pressure sensors made from continuous carbon fibers.

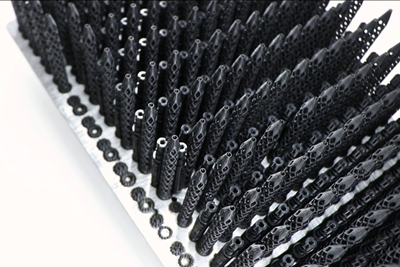

WatchUltra-Complex 3D Printed Scaffolds Enable Cell Growth: The Cool Parts Show #70

Perhaps the ultimate surface-area challenge is in bioengineering: creating structures that can grow sufficient cells within a compact volume to be effective for leading-edge medical treatments. The Southwest Research Institute develops bioreactor scaffolds that could only be made using 3D printing.

WatchImplicit Modeling and Metamaterials: The Cool Parts Show All Access

Metafold CEO Elissa Ross describes one of the promises of more effective modeling of geometrically complex 3D printed forms: expanded use of metamaterials. To what extent can material “properties” come from geometry rather than the material itself?

Watch7 Things You’ll Learn at the NPE2024 3D Printing Workshop

Are you a molder, toolmaker or OEM looking to adopt 3D printing? Here are 7 lessons about this technology that will be explored during a workshop at NPE2024: The Plastics Show.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreComplete Speaker Lineup Announced for the 3D Printing Workshop at NPE2024: The Plastics Show

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More