Three years ago when Tangible Solutions' implant manufacturing business got underway, the company had just two clients and was manufacturing just three FDA-accepted medical devices on its six Concept Laser machines. That small amount of work alone was hard-won, the result of years of planning, extensive work and collaboration with the FDA, ISO certification, house mortgages, sleepless nights and more. But company cofounders Chris Collins and Adam Clark were willing to take the risks they took, to put in the work, because they believed in the promise of additive manufacturing (AM) and that it would, with or without them, disrupt the implant industry.

But better that this disruption happen with them, and with Tangible Solutions. The Fairborn, Ohio, business now serves several dozen customers and produces more than 40 FDA-recognized medical devices with another 20-plus in the works. The company that started with a couple of guys in a garage now employs more than 30 at its industrial facility near Dayton.

A company that could not so long ago be described as a startup has fully established itself as a production-scale additive manufacturer. Titanium implants produced at Tangible Solutions’ Fairborn, Ohio, facility are printed on one of its now 10 metal 3D printers, then flow toward the back of the building for machining, cut-off, deburring and cleaning.

Despite exponential growth — more than 600% in the last two years, Collins estimates — there are some things that remain unchanged at Tangible Solutions. Its core marketplace is still 3D printed medical implants, primarily for the spine sector, and it has stayed committed to its Concept Laser (now GE Additive) laser powder bed fusion (LPBF) capabilities. Even the material is the same — despite growing interest in 3D printing of cobalt chrome and other biocompatible alloys, Tangible Solutions has not wavered from titanium.

But as a result of this laser focus on marketplace, material and technology, the additive manufacturing is no longer Tangible Solutions' challenge. Laser powder bed fusion doesn't keep the company's founders up at night, because they have found a reliable “workhorse“ printer in the Concept Laser MLab machines, Collins says, and larger capacity using the same technology in the M2s. They also aren't worried about helping clients through FDA certification, because it's a process they've now been through many times over. They aren't concerned about cleaning complex spine cages or fixation devices, because they've created a test coupon more tortuous than any medical implant and developed a process to clean it. The coupon is a valuable test piece, promising, “If we can clean this, surely we can clean the part you've designed,” they say.

It took time for Tangible Solutions to dial in the process for manufacturing the kinds of complex, intricate spine implants like this one that the company produces. But now that they have it down, the cofounders’ focus is shifting away from the technical difficulties of production. Photo Credit: Tangible Solutions

In short, Collins and Clark have worked hard to remove variables and distractions in the production process. The company’s work is strictly medical implants, strictly in titanium, and strictly on one family of machines — the parameters of which were developed from scratch and are never changed. Collins and Clark have therefore reached a point that many additive manufacturers might aspire to: Tangible Solutions can now take the additive manufacturing for granted. The technology works, and so too does the process built around that technology. “We are building simplicity into the system,” as Collins puts it.

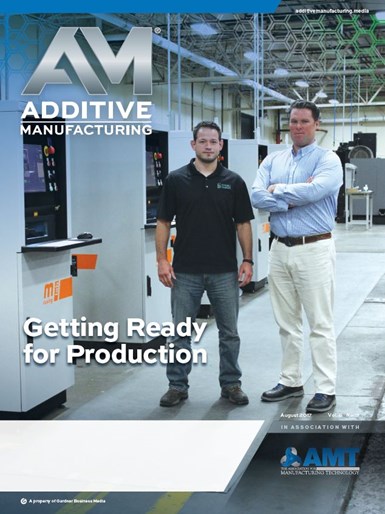

Chris Collins (left), chief operating officer, and Adam Clark, chief executive officer, co-founded Tangible Solutions in 2013. For the first part of the company’s life, it operated like a startup in order to work out the kinks in medical device manufacturing via AM. Now, its challenges have less to do with the production technology and more with business concerns. Photo Credit: Tangible Solutions

Growing Pains in an Additive Manufacturing Business

Now, the growing pains Tangible Solutions is facing are of a different sort altogether. They have to do with 3D printing in some cases, but others would be recognizable to any manufacturing business, or even any business generally. Here are seven challenges the company has confronted:

1. Outsourcing some business services

Like most small businesses starting out, Tangible handled its own needs related to information technology, accounting and human resources. But these activities were a drain on the founders and prevented them from getting to the real work. Tangible Solutions today has a hired IT company that handles its technical needs, and an accountant on staff. And while much hiring still takes place through word of mouth, the company also works with a recruiter to fill certain job openings. Outsourcing these activities to specialists frees Collins and Clark to focus more of their attention on running the business. The company now even has its first salesperson, a marketing move that will help identify more business.

2. Insourcing more of the technology

A Bridgeport machine dedicated only to resurfacing build plates allows Tangible to keep this process in-house without taking up valuable cutting time on its five-axis machining centers.

Since the early days of the Fairborn facility, Tangible Solutions has always had postprocess machining capabilities onsite. Its first Hurco machining center has been joined by several more, along with a wire EDM.

But perhaps the most interesting addition to the floor is a more basic machine: The company recently invested in a manual Clausing mill that is fully dedicated to refinishing its build plates. This work was previously farmed out to another company because it didn't make sense to utilize five-axis machining centers for this task when they could be finish machining implants instead. Now, the mill allows Tangible to keep build plates in house and ready when they are needed. Laser marking and passivation capabilities have also been added, again for the sake of controlling the timeline on the production parts.

3. Implementing and customizing an ERP system

Taking inventory by hand was unsustainable as Tangible Solutions grew to production scale. While not perfectly suited to AM, the ERP system it uses now helps to standardize its processes and keep track of parts in work. Photo Credit: Tangible Solutions

When the company first started out, Clark recalls, inventory was counted by hand — hardly an efficient way to operate in a production-scale environment. It's been a learning curve to implement an industrial enterprise resource planning (ERP) software suite, but one that has helped to standardize the work happening across the business. That said, the program is not perfect for the needs of a business predicated on AM.

“Powder isn't the same as barstock,” Collins explains. “We don't use it just once and it's gone. It gets used and reused, and we need traceability.” The current ERP system is a step in the right direction, but as more production businesses spring up around AM, it seems clear that business software and services will need to adapt.

4. Balancing capacity and workflow

When Tangible first moved into its current building, 3D printers outnumbered the machining center five to one. Now, there are 10 printers and six vertical mills, a reflection of how much work has shifted into production. But maintaining the right balance is an ongoing challenge that only increases with each new job won. Scaling involves not just adding new printers but ensuring that there is enough open capacity for machining and other downstream operations before doing so.

“Process improvement is the name of the game,” Collins says. “Running a job through the system is the experiment now, not the part itself.”

Today Tangible Solutions operates three large-format Concept Laser M2s and seven smaller MLabs. All print in titanium, and materials and settings are never changed. Eliminating variability in the 3D printing process means that the actual build is no longer the main hurdle to production.

5. Serving increasing demand

Tangible Solutions is acquiring new business in several ways. First, it is attracting the attention of implant developers who may have experimented with in-house additive manufacturing, but are now finding the challenges of AM to be too much to support full production. Tangible Solutions can step in to pick up where these companies wish to leave off. Second, it is attracting larger companies with bigger orders and portfolios; managing the flow and pace of work becomes particularly important when dealing with the large quantities these businesses can require. Third, it continues to work with smaller or less experienced medical device companies to develop new products.

“The term ‘contract manufacturer’ means a lot more at Tangible Solutions,” says Clark. “It's a long-term partnership.”

“We can walk them all the way to the door of [FDA] clearance,” Collins adds, “and if you clear those hurdles for the customer, possibilities get unlocked.”

Postprocessing of implants takes place in this space on Tangible Solutions’ production floor. The company handles everything from part cut-off to machining to deburring.

6. Investing in company culture

As the staff has grown, Collins and Clark have had to tease out the kind of business ethos they want to develop at Tangible Solutions. Days start early, with a daily 6:30 a.m. check in with all the staff, and go late until 5:30 or 6 p.m. Employees work these hours four days a week, and have Fridays off plus weekends. Since implementing the four-day workweek Collins and Clark say they've seen positive impact on productivity, and employees prefer the three-day weekend.

“It’s a shorter sprint, followed by a longer rest,” Collins says. But when people are in the building, communication is paramount. Weekly meetings and daily check-ins are part of the routine, a way to identify problems before they become serious and help all team members understand the shared mission they are working toward. Sometimes the value is in something as simple as noticing a discrepancy that could make an employee feel alienated or less able to do their job — an uncomfortable chair, or a tool that is outdated that should be replaced.

“Removing all obstacles is our drive now,” Clark says.

7. Learning to delegate

Chris Collins (left) and Adam Clark were featured on the cover of Additive Manufacturing Magazine in August of 2017, as Tangible Solutions was ramping up toward implant production. Much has changed since that story.

I've known Tangible's cofounders for more than five years now, and I've seen their optimism about 3D printing, their vision for additive manufacturing production, their drive to develop a reliable, repeatable production process for medical devices. But I've seen them mostly as founders, creators of this startup company on its way. So it was particularly striking on this most recent visit to hear Clark say, “There's been a real switch, from entrepreneur to executive,” in describing the evolution of the cofounders’ mandate. But the switch is visible. The roles that he and Collins are stepping into look less like that of optimistic visionaries, and more like pragmatic leaders.

“You can't act on everything,” Collins acknowledges. “We are delegating authority, not responsibility.”

“We have to put trust in our employees to improve the business,” Clark adds. “Now only the toughest decisions make it to us.”

That's not to say Collins and Clark are content to rest on what they've already accomplished. Instead, they see what they've built at Tangible Solutions thus far as the basis for future growth. “Every company needs to build a platform, which is what we've done here,” Collins says, “But then you need to support that platform. It's sustainment.”

The focus on implants won't change any time soon, but the business is expanding into new types of products like foot and ankle implants as well as fixation devices. Large joint and extremity implants could be on the horizon. And the company is bringing in bigger customers and larger order volumes that will challenge its existing capacity and possibly justify greater technology investment. The pains may change, but it seems that Tangible Solutions isn't done growing.

Editor’s note: The prediction above certainly proved to be true — just a few months after this story was published, Tangible Solutions was acquired by Marle Group, a global orthopedic company headquartered in France. The company’s Fairborn, Ohio, facility is now one of Marle’s eight global production sites focused on medical implants.

Related Content

AM 101: Digital Light Synthesis (DLS)

Digital Light Synthesis (DLS) is the name for Carbon's resin-based 3D printing process. How it works and how it differs from stereolithography.

Read MoreHow to Improve Polymer AM Productivity 20X

A fast cycle time is critical to efficient production 3D printing, but it’s not the only thing. How you choose the right parts for AM, prepare jobs for production, and manage post processing will have just as big an impact on total 3D printing throughput. It all needs to work together to achieve maximum productivity.

Read MoreHow to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

Read MoreHow to Pursue a Career in Additive Manufacturing

AM professionals are in demand as 3D printing matures and advances. But what skills are hiring manufacturers looking for? How can applicants prepare? And where can you find relevant job listings?

Read MoreRead Next

Topology Optimized 3D Printed Spine Implant: The Cool Parts Show #2

Medical contract manufacturer Tangible Solutions shares a titanium 3D printed spine implant with an unusual lattice structure in this episode of The Cool Parts Show.

Read MoreBuilding an Additive Manufacturing Business for Production

What does it look like to build a business based on AM production from the ground up? An Ohio medical device contractor is finding out.

Read MoreView From My Shop: 3D Printing and Postprocessing With Tangible Solutions

Collaboration between Tangible Solutions’ additive and machining departments simplifies their work. Learn more in this episode of The View From My Shop.

Read More

.jpg;width=70;height=70;mode=crop)