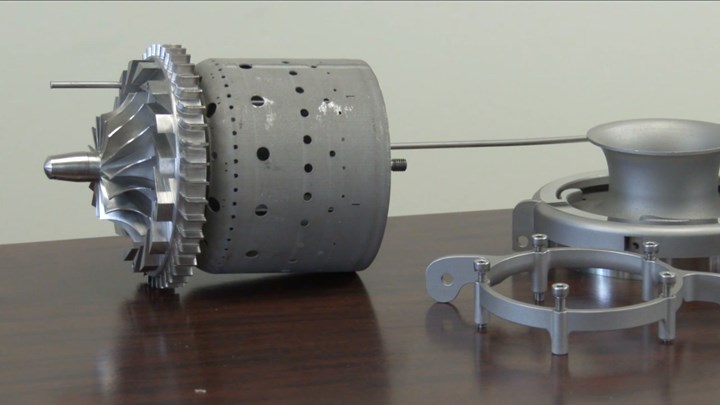

Video: Miniature Jet Engine Made with Additive Manufacturing

GE engineers started with a radio-controlled engine and redesigned it for additive manufacturing. This model manufacturing exercise illustrates important real points about additive manufacturing as a production option.

Share

Read Next

GE produced this video about a working jet engine model that was created through additive manufacturing and run in a GE Aviation test cell. The video briefly documents the manufacturing process that produced in this engine, a process that illustrates at least two significant points related to additive manufacturing. They are:

1. Design freedom. Because it makes parts that machining can’t produce, additive manufacturing offers the opportunity to reengineer parts and assemblies for greater performance. GE’s engineers started with a radio-controlled aircraft engine, but then they improved its components for additive manufacturing. (They also further improved them by making them from high-temperature alloys a radio-controlled engine wouldn’t normally use.)

2. Secondary operations. Additive manufacturing makes intricate parts, but it does not necessarily make finished parts. The video shows this. The parts that were produced additively (on an EOS M270 machine) went on to receive secondary machining and finishing steps. The same will almost certainly be true of any production metal part made through additive manufacturing.

Related Content

-

6 Reasons Space Exploration Will Need Additive Manufacturing

There are at least half a dozen ways 3D printing will contribute to space travel, research and habitation — and in some cases it already is. Insights from seminar focused on manufacturing challenges for the space sector.

-

How Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

-

Qualification Today, Better Aircraft Tomorrow — Eaton’s Additive Manufacturing Strategy

The case for additive has been made, Eaton says. Now, the company is taking on qualification costs so it can convert aircraft parts made through casting to AM. The investment today will speed qualification of the 3D printed parts of the future, allowing design engineers to fully explore additive’s freedoms.

.jpg;width=70;height=70;mode=crop)