Video: Industrializing Additive Manufacturing for Automotive

A number of components for the Bugatti Chiron sports car spoiler were reimagined for additive manufacturing, unleashing several performance improvements.

Share

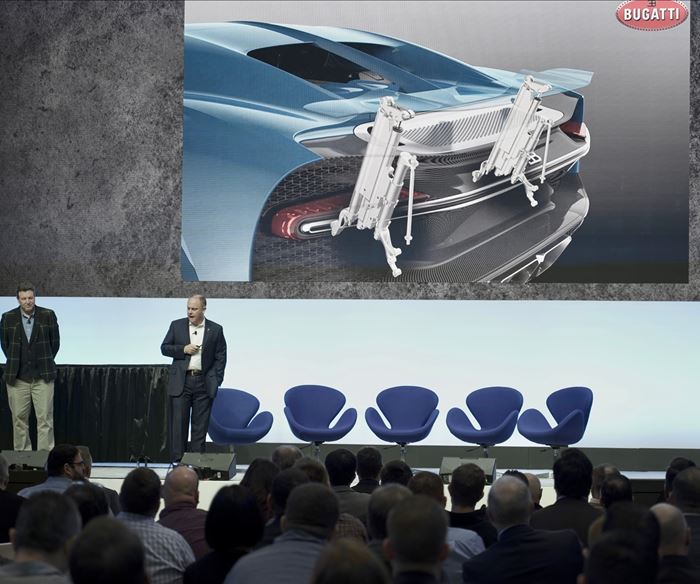

The North American International Auto Show (NAIAS), which took place this year in Detroit on January 16, has always been known as a flashy affair. And when it was time to talk about additive manufacturing innovations for the Bugatti Chiron sports car at the inaugural Additive Manufacturing Workshop for Automotive, the presenters didn’t disappoint. Chris Weber, Director of AM Portfolio Development, Siemens PLM Software, and Douglas Ramsey, Chief Development Officer, Hackrod, used their presentation to outline the collaborative process they’ve undertaken to industrialize the additive manufacturing process. “This is the most exciting time in my career of 30 years,” Weber said.

Projected behind Weber as he spoke was a closeup image of the Bugatti Chiron that focused on the “wing active control system”—a hydraulically powered spoiler that helps keep the car on the ground when traveling at speeds up to 240 mph. In the video of Weber and Ramsey’s presentation—which you can now watch for free by simply registering here—Weber highlighted aspects of the control system that were reimagined for additive, including the bell crank, the shuttle, carbon-fiber tubes, and attach point brackets. He said that the end result was an “innovation process” that was accelerated tenfold, reduced aerodynamic drag and lightweighted the system by 50 percent.

Weber and Ramsey also discuss how additive’s rapid technological progression for the auto industry is equal or greater to innovations experienced decades ago for CNC machining and stamp metal technologies. Ramsey talks about his work with Hackrod and tells the story of the La Bandita speester, the first car designed in virtual reality with a chassis and other large structural components 100 percent 3D printed. Check out the video to see why Ramsey predicts this process will someday be achievable “while playing a video game.”

Related Content

-

A Tour of The Stratasys Direct Manufacturing Facility

The company's Belton manufacturing site in Texas is growing to support its various 3D printing applications for mass production in industries such as automotive and aerospace.

-

Do Distributors Dream of Digital Inventory? Würth Additive Group Does

It’s more than a dream for Würth Additive Group and its parent company, in fact. Along with supplying additive equipment, the group is now developing solutions for sourcing 3D printed parts in a reliable, elastic digital inventory model.

-

Seurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.