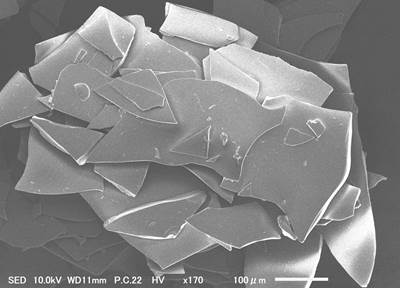

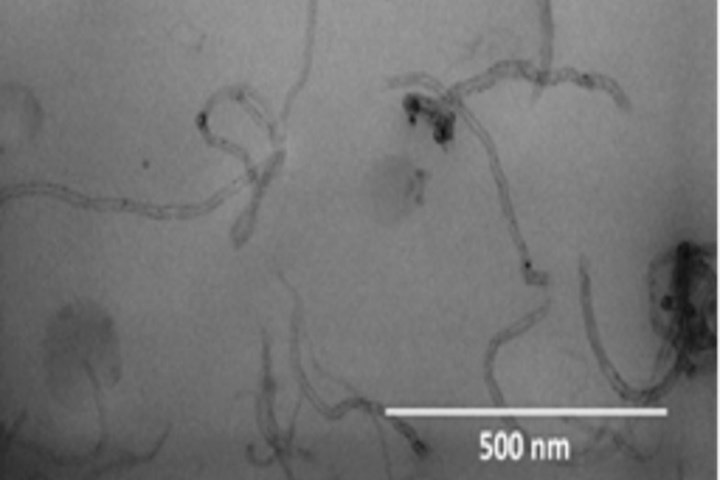

When examined at the nano level, the problem looks something like the difference between steel rebar and a cotton ball. The former — strong, straight, laid with intention — speaks to the promise of carbon nanotubes (CNTs), tiny tubes of carbon with the potential to impart their own strength and material properties to broader systems. But the latter — random, jumbled, unplanned — illustrates what has, until recently, been the reality for carbon nanotubes. Despite their potential, CNTs have been largely unworkable as a material additive because of their tendency to clump together, forming tangled masses rather than reinforcing structures.

But no more. Just emerged from stealth mode in May of 2021, Arizona-based startup Mechnano is commercializing carbon nanotube technology for additive manufacturing (AM). Beginning with a UV-curable resin with electrostatic dissipative properties, Formula 1, Mechnano is out to show the AM world the promises and applications for this hitherto unusable material.

Unraveling the Carbon Nanotube Problem

At a basic level, carbon nanotubes are sheets of carbon a single atom thick that are grown in the form of a tube. Dual or multiple walled CNTs are possible through forming these tubes concentrically around each other to impart different properties. As a raw material, CNTs are stronger than steel, more conductive than copper, and as tough as diamond, not to mention their impressive thermal properties. But none of this matters, of course, if they can't be applied to real materials and applications. While there has been plenty of buzz regarding the promise of CNTs since the discovery of hollow graphitic carbon tubes in the 1990s, in practice the tubes tend to fold up on themselves into “cotton balls” that can’t be untangled.

Past efforts to manufacture and use carbon nanotubes (CNTs) have typically resulted in tangled masses of these tiny strands. Mechnano has developed a process that keeps the CNTs dispersed, as shown here. Photos: Mechnano

The difficulty of working with these materials is the roadblock that kept Mechnano CEO and cofounder Steven Lowder from pursuing opportunities with CNTs for decades. With 30 some years in high-tech industries like semiconductors and electronics, Lowder encountered several chances to acquire or collaborate with CNT manufacturers or organizations developing interesting technologies around carbon nanotubes. He passed on all of them.

"None of these strategies could really deliver on the benefits of CNTs," he says. "Theoretically it was possible, but in practice it was problematic."

That is, until a close friend Scott Gillette urged him to examine a new CNT technology. Lowder looked into it as a favor, but was struck by the real potential of what he found. "This might work," he thought. After more than a year of testing and investigation, Lowder and Gillette were convinced. "We kept looking for the problem," Lowder recalls, "and we couldn't find one."

The technology that ultimately formed the basis of Mechnano is a proprietary manufacturing process that allows for the production of discrete carbon nanotubes that stay separate, even when suspended in a liquid or dispersed throughout a product. The nanotubes will not tangle with each other, fall out of the material, or otherwise degrade its performance. On the contrary, these discrete CNTs can deliver strength and other performance improvements at a nano scale that then boost the micro- and macro-level properties of the material or product.

Incorporating carbon nanotubes into materials makes it possible to impart characteristics such as electrostatic dissipative (ESD) properties, important for items such as this electronics housing.

Mechnano has found that by manipulating the properties of the carbon nanotubes themselves (introducing more walls, adjusting the aspect ratio of length to diameter) it is possible to tune the material to disperse within an additive manufacturing feedstock and bring greater strength to the final print. But the carbon nanotubes themselves can also function as vehicles that deliver other types of additives and properties, such as conductivity or magnetism.

"We 'functionalize' the carbon nanotubes first with these properties," Lowder says, "and then work to disperse them throughout the system."

Functionalized Nano-Level Additives

Now out of stealth mode, Mechnano is bringing these functionalized CNTs into materials for 3D printing. (When asked "Why additive?" Lowder simply replies that it was the industry sector most clearly calling for help in terms of material properties.)

Its first material, Formula 1, is a case study in how these additives can be applied to improve the end result of a print, in this case to introduce electrostatic dissipative (ESD) properties. The product combines CNTs with liquid polymer resin to create a material suitable for photopolymerization 3D printing. One of Mechnano's core tenets is that any CNT-enhanced material should be compatible with existing 3D printing technologies, therefore no special equipment is needed and the resin should work in any off-the-shelf stereolithography (SLA), digital light processing (DLP) or similar system, the company says. Unlike micro-level additives such as chopped carbon fiber, once dispersed the carbon nanotubes stay dispersed and require nothing more than the usual stirring or shaking before use.

To create Formula 1, Mechnano first functionalized the CNTs for the desired ESD properties, and then further optimized them for resin-based 3D printing which introduced a challenge: Photopolymerization depends on UV radiation to cure the polymer, and CNTs happen to be very efficient at absorbing radiation. Simply adding CNTs to a resin might result in a material that absorbs the UV light without curing. To make it work, Mechnano had to create a low-energy (LE) absorption CNT. These LE tubes can now be used in resin 3D printing without disrupting polymerization.

A resin 3D printing build made with the Formula 1 ESD material.

It could be argued that Mechnano has started with the hardest applications first, those where the CNTS must be held in suspension, but carbon nanotubes have usefulness beyond photopolymerization processes. The company is already looking at other modalities where CNTs could make a difference: filaments for fused filament fabrication (FFF), powdered polymers for selective laser sintering (SLS); or within the binding agents or metal powders used in binder jetting. The CNTs could even be applied to micro-level fillers such as chopped carbon fiber to help them disperse better in a material or impart other properties. But, one thing at a time.

"We have not even done the full functionalization on UV curables," Lowder says. The Formula 1 ESD material is only an example of what is possible, and the company expects to follow this with new resins optimized for electromagnetic interference (EMI) shielding, radiation hardening, thermal resistance or transfer, tensile strength, and magnetics. While there are already many applications in sight, Lowder expects that as these other possibilities become viable, more use cases will emerge.

"Imagine for instance a magnetic LEGO," Lowder says by way of an example. "It may not be the most practical application, but it gets people thinking about the possibilities."

Photopolymerization and ESD resins are just the beginning. Mechnano expects to continue expanding its portfolio of resins for this process, while also exploring materials for other 3D printing modalities.

Nano Improvements with Macro Implications

The Formula 1 resin aside, Mechnano's aim is not to be a materials supplier. Rather, the company is seeking partnerships with material formulators and suppliers who want to collaborate in creating new CNT-capable materials. Its first publicly announced partnership, with Dymax, will focus on infusing that company's oligomers with CNTs. More partnerships and materials will follow.

On a broader scale, Lowder believes that CNTs have the potential to change the way additive manufacturing users approach new challenges. "Until now we've been trying to formulate our way out of problems," he says, citing new chemistries and material formulations as a go-to strategy for bringing desired properties to 3D printing. But carbon nanotubes offer another route: Instead of beginning with chemical formulation, AM users could look at their materials through a nanoscale lens.

"We can achieve these properties at the nano level to provide better benefits throughout the whole build," Lowder says.

Related Content

How Large-Format 3D Printing Supports Micro-Scale Hydropower

There is potential hydroelectric power that has never been unlocked because of the difficulty in capturing it. At Cadens, additive manufacturing is the key to customizing micro-scale water turbine systems to generate electricity from smaller dams and waterways.

Read MoreAircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

Read More3D Printed Preforms Improve Strength of Composite Brackets: The Cool Parts Show Bonus

On this episode, we look at a pin bracket for the overhead bin of an airplane made in two composite versions: one with continuous fiber 3D printed reinforcements plus chopped fiber material, and one molded from chopped fiber alone.

Read More8 Social Media Posts About Additive Manufacturing: AM Radio #34

Cost savings, modifications, large-format AM and more. In this episode of AM Radio, we discuss what people are saying about additive manufacturing on social media.

Read MoreRead Next

Is There a Larger Role for Additives in Additive Manufacturing?

Terminology confusion might be coming, because the answer is likely yes. A provider of glass flake for plastics foresees applications to AM, specifically as a reinforcement within 3D printing filament.

Read MoreOrion Gets a Lift from Electro-Static Dissipative (ESD) Material

NASA’s Orion spacecraft will include parts 3D-printed from electro-static dissipative Antero 800NA from Stratasys. Developing this material was an exercise in working within constraints.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More

.jpg;width=70;height=70;mode=crop)