This Company Is Developing Software to Make Any Industrial Robot Into a 3D Printer

Do robots offer additive manufacturing capacity just waiting to be unboxed?

3D printing is multiple decades old, but additive manufacturing arguably is not. The arrival and recognition of additive digital layering processes as a potential means of making functional components, across a wide variety of industrial applications, is a threshold crossed more than one decade ago, but less than two. Against the time span of manufacturing technology development, that is very recent development. Additive is so new, it is likely we have not yet seen the extent of what it will be in its fully realized state, and all the ways it will perform.

I thought about this recently during a conversation with the French-Swedish technology startup Adaxis — specifically, with its CEO, Emil Johansson. Adaxis is developing software that aims to make any industrial robot easy to program for deposition-style 3D printing.

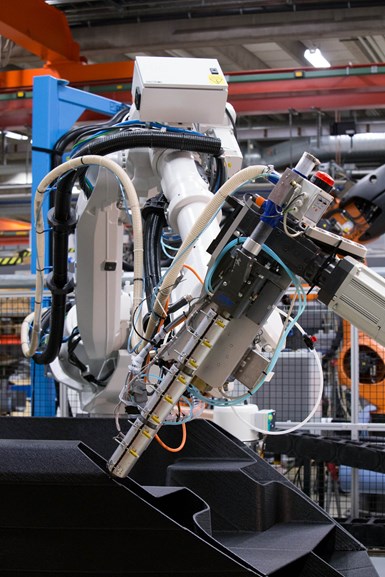

A robot employing its range of motion could print an angled form by following the angle, as seen here, rather than layering a stairstep. It could also follow a complex form like that of the surface of a tool. Photo: Adaxis.

Robots and AM naturally fit together. Others see this — one robot producer just introduced new functionality allowing its robots to be programmed for 3D printing from slicer output. But Adaxis aims to go farther, seamlessly connecting CAD systems and robot programming languages so that CAD models can seamlessly become 3D printing programs that (importantly) make full use of the robot’s rotating and pivoting range of motion. The firm is now working with major CAD software formats and working to support major robot producers (so far including ABB and Kuka) aiming toward this goal. Because robots are so commonplace and multi-axis deposition is so freeing, this development might expand our picture of what additive manufacturing itself entails.

Indeed, even for as wide a range of processes as additive manufacturing has come to encompass, it is still possible that the picture we have developed is too narrow. We tend to imagine 3D printing happening inside a 3D printer. It might be a desktop model costing hundreds of dollars or a powder bed fusion machine costing hundreds of thousands, but the principle is the same: A part is grown inside a box in straight parallel layers perpendicular to the Z axis of motion. But what if this is just a part of what AM will come to be? What if this mode of fabrication — flat layers within a box — comprises only a portion of how AM will ultimately be deployed?

Fully empowered robots for 3D printing potentially bring AM that is different in all these ways:

1. No box. Depositing material doesn’t involve high forces the way molding or machining does, so 3D printing does not need the rigidity of a machine structure all around. Printing could happen wherever a robot could reach. Possibilities include robots collaborating on big parts or printing parts onto the conveyor of an automated line.

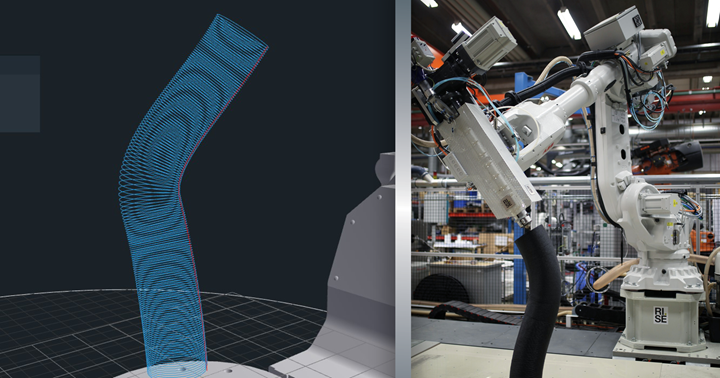

2. No slicer. Slicer software assumes straight, parallel slices. A different programming system such as Adaxis’s that makes use of the full range of motion of the robot can mean adapting the angle of a given layer to the geometry of the part in that region, as well as printing onto existing forms by following their geometry — to modify or repair an existing die, for example.

3. No dedicated machine. This difference might be strangest of all. We are accustomed to manufacturing operations having purpose-built machines. Grinding is done on grinding machines, for example. But in the future, a significant share of AM might be performed on robots that manufacturers also use for other purposes. The polymer extruder or metal DED head might be just another end effector.

This last point is particularly significant, because it potentially makes AM so accessible, and therefore (in a good way) so mundane. Certainly a large portion of manufacturers have robots, and many of these robots are currently underused. Today they are difficult to program for 3D printing, but tomorrow, if that obstacle is removed, then all those robots become additive manufacturing capacity that is just waiting to be put to use.

This demonstrator part made by the Research Institutes of Sweden using the Adaxis software shows the possibilities for altering layer orientation in robotic 3D printing. The slicing planes for the curving cylinder change continuously based on a spline that follows the centerline the part. This means layers are not parallel. The output of the extruder varies to create the difference. Photo: Adaxis.

Related Content

Formlabs Part Removal Mechanism Enables Lights-Out Production

A build platform overcoming the need for manual part removal enables automated part handling, and therefore continuous production from one build cycle to the next.

Read MoreUnderstanding HP's Metal Jet: Beyond Part Geometry, Now It's About Modularity, Automation and Scale

Since introducing its metal binder jetting platform at IMTS in 2018, HP has made significant strides to commercialize the technology as a serial production solution. We got an early preview of the just-announced Metal Jet S100.

Read MoreRobot Deposition Makes Giant Industrial Mixer Blade: The Cool Parts Show Bonus

Wire arc additive manufacturing produces a large component formerly made through casting, and allows for redesign of its internal cooling geometry.

Read MoreLarge-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

Read MoreRead Next

Why Robots and Additive Manufacturing Go Together

3D printing and robots enable one another. We miss the possibilities of one if we do not consider the other. The combination includes AM for end effectors, robots for 3D printing parts, and different modes of metal and plastic production.

Read MoreABB Introduces Software Capabilities to Simplify Robot Programming for AM (Includes Video)

Slicer software output can be converted to a robot program. The user chooses speed and precision of printing, but no specialized knowledge of robot 3D printing is needed.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More