The Manufacturing Network as a Source for Internal Custom Tooling

For a tool that includes both machined and 3D-printed components, all the pieces of the tool can be made by separate companies yet arrive together. BMW has used Xometry to obtain tooling in this way.

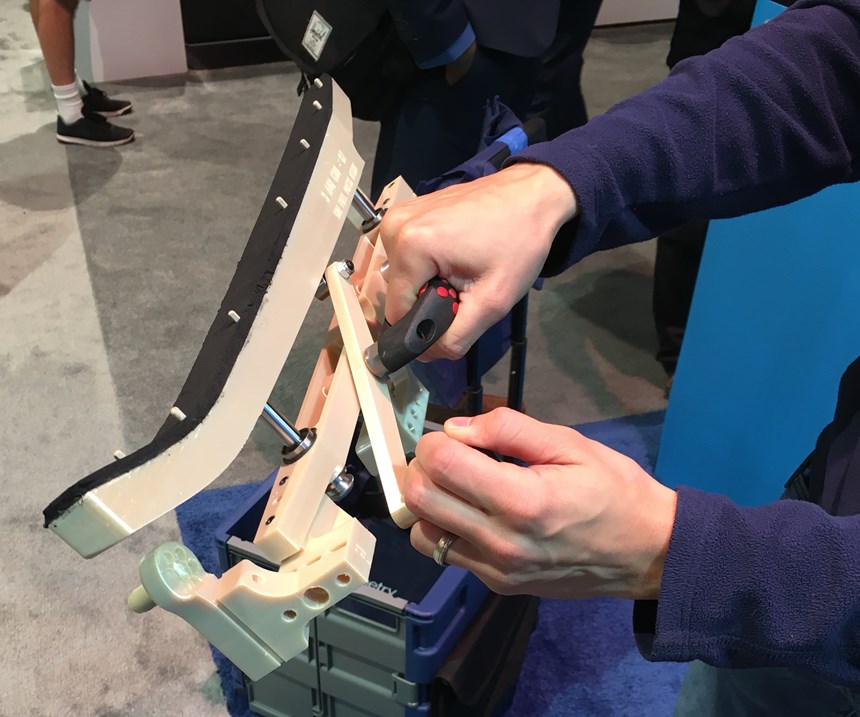

A tool can be a tall order. A custom tool developed to aid manufacturing—for example, a tool developed to aid the worker performing a specific, challenging assembly operation—represents a one-off or short-run order that can be difficult to obtain quickly or economically. More than that, if the tool involves actuation, then the separate moving parts actually represent multiple one-off or short-run components. 3D printing can provide the quickest and cheapest way to produce the components in some cases, but only some cases. In the typical engineered tool featuring moving parts, some components are 3D printed and some are machined, likely meaning different groups must deliver the pieces needed.

Xometry, at the recent International Manufacturing Technology Show (IMTS), focused on this challenge and the opportunities the company can offer to simplify tool creation. Xometry is the manufacturing platform connecting a network of some 2,400 machine shops, 3D printing service bureaus and other independent manufacturers. The company is sometimes imagined (incorrectly) as a contract manufacturer, but in fact it serves the role of receiving, managing and standing behind manufacturing orders without performing any manufacturing itself. “We are a tech company that happens to provide parts,” says Gregory Paulsen, director of applications engineering.

Amazon is a good analogy for the service Xometry performs, says Paulsen. “On Amazon, you buy five things supplied by five companies, but they all come in one box.” Xometry is able to provide the same thing: All the components that are part of the order for a single tool—whether those parts are machined, 3D printed, or some of each—arrive together in a single shipment. That level of coordination can be difficult to obtain even for tooling sourced internally.

At IMTS, Paulsen showed me examples of some of the tools Xometry has helped produce. BMW is a case of a manufacturer using the network in this way. Engineers at BMW design custom tools for use in production assembly processes, but in some cases they no longer have to employ internal resources to get those tools made. Instead, the models for all of a tool’s components can be uploaded to Xometry. The site provides instant pricing and leadtime quotes, and the ability to check out online. From there, for all the engineer knows, Xometry might then have every piece of the tool produced by some different supplier in the network. BMW then just has to assemble the tool when all its components arrive together.

Related Content

-

3D Printed Golf Putter Shafts: AM Tailors Weight Distribution for an Optimized Putting Stroke

Snarr3D offers high-performance golf putters with aesthetic features made possible through 3D printing. In manipulating the weight distribution of the golf putter shaft, Snarr3D aims to enhance accuracy and performance to give golfers the equipment suited to their individual game.

-

Next-Gen Horse Trailers to Be Built With Robotic 3D Printing

Double D Trailers is currently developing a prototype horse trailer that will be made with large-format additive manufacturing. The technology brings potential benefits for labor, weight and design features to this subset of recreational vehicles.

-

Why AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.