This Rocket Fuel Injector Is a Solid Part That Contains a Working Motor: The Cool Parts Show #1

Our new video series debuts with a look at a solid metal part made through additive manufacturing that was built with a motor embedded inside. The motor sealed within the part adjusts the rocket’s fuel mixture while the rocket is in flight.

Welcome to the first episode of Additive Manufacturing’s video series, The Cool Parts Show!

In this episode, hosts Stephanie Hendrixson and I look at a rocket fuel injector made by Fabrisonic for TGV Rockets & Propulsion Systems using ultrasonic additive manufacturing, a type of sheet lamination. The solid-state metal AM process (no high heat, no melting) made it possible to build a solid part to contain a motor without harming the motor during the build.

The Cool Parts Show is a video series from Additive Manufacturing that explores the what, how and why of unusual 3D printed parts. Watch more here.

Have a cool part to share? Email us.

Transcript

Peter Zelinski, Additive Manufacturing

Additive manufacturing will change what parts are possible! I'm Pete Zelinski

Stephanie Hendrixson, Additive Manufacturing

And I'm Stephanie Hendrixson with additivemanufacturing.media. Welcome to The Cool Parts Show! This is our new series where we talk about cool parts 3d printed by viewers like you. So Pete you have a part here to help us get kicked off.

Peter Zelinski

I have a way cool part! So Stephanie you know how one of the promises of additive manufacturing is internal features?

Stephanie Hendrixson

Sure lattices, conformal cooling, that kind of thing.

Peter Zelinski

Right. So now think internal objects.

Stephanie Hendrixson

like sensors?

Peter Zelinski

Yeah. But take it even farther. Imagine a solid part with a complete working motor embedded inside. That's what this is.

Stephanie Hendrixson

Sounds like a pretty cool part. But what is it?

Peter Zelinski

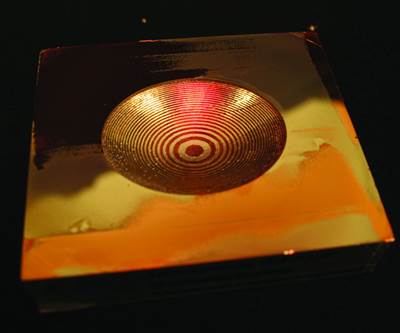

It is a cool part! This is a rocket fuel injector, designed by TGV. Fuel injector, mixing fuel and oxidizer during the rocket launch, usually a solid part. This one uses that motor that's inside to precisely control this pentil, controlling the openings of these orifices changing the mix of fuel and oxidizer in flight.

Stephanie Hendrixson

So this looks pretty solid, and you're saying there's a motor embedded in there. How do you get the motor in there and not damage it with metal 3d printing?

Peter Zelinski

This was made using a solid state additive manufacturing process. There was no melting involved, there was no high heat, the motor was never in danger. This was made through ultrasonic additive manufacturing. It was made by Fabrisonic, Mark Norfolk, CEO of Fabrisonic describes the process.

Mark Norfolk, Fabrisonic

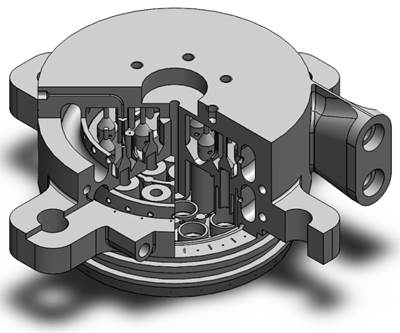

So ultrasonic additive manufacturing is a type of 3d printing for metals. UAM is little bit different in that we're taking thin foils of metal on the order of five to 10 thousandths of an inch. And we're welding those together using ultrasound. The secret sauce there is we're not actually melting anything. This is all happening at room temperature. This part right here never got above about 200 F. So the lowest temperature on your oven at home, that's as hot as we ever get. Metals really like to stick to other metals. And if you take two pieces of metal here on Earth, they are always covered with an oxide layer. So if I take this sheet and I fold it over and I try to press it down, it doesn't bond. But with ultrasound, we can actually scrub away that oxide layer and put virgin metal on virgin metal. So what we do is we fold over the foil onto the material we want to bond and we roll over that with what we call an ultrasonic welder. As it rolls over, it's vibrating this sheet back and forth on the order of 20,000 times a second. That vibration actually scrubs off any impurities any oils and most importantly scrubs off the oxide layer. As soon as you have virgin metal touching virgin metal, mother nature takes over and you get a solid state bond.

Peter Zelinski

So what really struck me and captivated me about that is the oxide layer. Every metal part in the world is basically wrapped in saran wrap. If you do ultrasonic scrubbing, to get that saran wrap off, like metals want to bond with like metals, they want to mush together, and just that mutual mushing is enough to make a solid part.

Stephanie Hendrixson

Yeah, and so through that process, you're able to build things like this without damaging the motors or sensors or anything else that you might want to embed inside. Okay, so if fuel injectors are usually this static thing, why would you want to put a motor inside of one?

Peter Zelinski

Yeah, so if it's just a static fixed part, then you get one mix of fuel and oxidizer. This one gives you a variety of different mixes that you can control. It now becomes possible to throttle up, throttle down the mix of fuel as the rocket is launching, according to a programmed path to get exactly the thrust profile that you want for the launch.

Stephanie Hendrixson

So why would you 3D print something like this? Couldn't you just assemble it?

Peter Zelinski

Yeah, you could. So that's kind of the way you ought to do it right is this is in different parts, you drop the motor in there, bolt it together, and it's held in place. The problem is, what TGV decided, there is no way to get a tight enough assembly to absolutely guarantee you won't get unintended mixing of the fluids. The only way to keep those fluids separate, keep the streams apart, is a completely solid seamless part.

Stephanie Hendrixson

Alright, so one more question for you. All of this seems to be the same material except for this band right here. What is this?

Peter Zelinski

That's right. This is all aluminum except that band is copper. Another ability of this process, ultrasonic additive manufacturing, it makes building with dissimilar materials in the same part pretty easy. Mark Norfolk also had something to say about that.

Mark Norfolk

Another interesting feature is we can print dissimilar metals. So if you look at the device, you'll actually see a thin ring a copper and that's actually acting as a seal. By printing that softer material in a very specific location that allows us to seal one fluid from the other very easily. Other things that we're looking at for future versions of this is actually stiffening that structure with some embedded embedded wires so that we can actually take out some mass. By adding high strength wires inside the aluminum matrix, we can get a much higher strength which allows us to shrink the wall thickness, if you will, which will hopefully allow for weight savings as well.

Stephanie Hendrixson

Alright, so to recap, this is a 3d printed fuel injector made with ultrasonic additive manufacturing. That process allows for a motor to be embedded inside, which controls this pintil on the top, which allows you to change the amount of fuel that's coming through and throttle your engine.

Peter Zelinski

So I think that's a wrap. That was our first episode of The Cool Parts Show. Tell us about your cool parts! Please email us coolparts@additivemanufacturing.media. Thank you for watching. Don't forget to subscribe.

Related Content

At General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreAircraft Engine MRO: How Additive Manufacturing Plus Robotic Finishing Will Expand Capacity for Blade Repair

AM offers the chance to bring fast, automated processing to individualized, part-by-part restoration of turbomachinery. A cell developed by Acme Manufacturing and Optomec is able to automatically repair 85,000 unique aircraft engine blades per year.

Read More“Mantis” AM System for Spacecraft Uses Induction for Deposition

The metal 3D printing system melts wire without lasers. 30-foot-diameter parts are built on a rotary-feed system that eliminates the need for a large machine frame or gantry.

Read MoreRead Next

AM 101: What is Ultrasonic Additive Manufacturing?

Going from additive to subtractive can be simple with Ultrasonic Additive Manufacturing (UAM). What is it and how does it work? Learn the basics in this 101 post.

Read MoreVideo: How Additive Manufacturing Is Advancing the Space Industry

By making launch vehicles more efficient and easier to manufacture, AM lets small companies play a significant role in space. Here is a conversation with an aspiring startup.

Read MoreAdditive Technology Delivers Small Satellites to Space

Researchers at the German Aerospace Center (DLR) have developed a reusable rocket engine specifically for the launch of small satellites. The complex injector heads are 3D printed which unlocks additional performance, reduces the parts count, speeds up production time, and reduces weight and costs.

Read More