Taking Rapid Prototyping To The Next Level

The rapid prototyping industry has been around a couple of decades. Historically applied for one-offs, it is seeing increased use as a method of direct digital manufacturing (DDM).

Although the rapid prototyping (RP) industry has been around for a couple of decades now, a more recent RP development has been the application of direct digital manufacturing (DDM). Because of the increasing sophistication of the parts being developed, there is the possibility that DDM could alter manufacturing trends, and as a result, lessen the incentive to outsource.

An Industry In Its Infancy

The need to present or develop tangible, accurate models of ideas, new products, buildings and so on has always been around. By the mid 1980s, prototyping processes were becoming more accessible as academics and industry workers experimented with building models layer-by-layer using rudimentary materials.

And so the RP industry was born with prototypes being developed in hours rather than days or weeks. The potential for a shorter product development cycle and lower bottom line costs was already becoming apparent.

As with most industries in their infancy, there were teething problems. The first prototypes produced were expensive, the materials were not the best for the job and build speeds were slow. The original machines were also prohibitively expensive and cumbersome to use.

Fortunately, the industry also had its champions. Manufacturing firms and designers in particular could see the vast potential. They could envisage how RP would help them avoid mistakes, prove theories were correct and get concepts to market quickly.

A Growth Spurt

By the early 1990s, RP users were becoming more specific about their needs, and the initial novelty created a demand for quality as a key deliverable. In only a few years, the accuracy, speed and precision of both machines and materials improved. Suppliers surpassed expectations and the service bureaus sector expanded, buying machines in order to offer their clients consistent accuracy and additional services, as well as considerably increasing their own output capacity.

Near the millennium, the first true RP machines came into being as they were developed for specific applications. Instead of simply refining earlier machines, developers focused on the relevant applications and specific needs of individual vertical markets, such as the automotive and aerospace industries. These two industries had the budgets to surge forward, as well as the foresight to become early adopters and drivers of this new wave of technology. They could see the payback.

Today the RP industry is global. Both Europe and Japan have long-standing mainstream and niche players, and Germany and Japan have benefited from major domestic programs. They have created a strategic RP infrastructure and culture that plays a key role in their economies. They, along with other European countries, remain important clusters of RP innovation.

Broadening The Scope

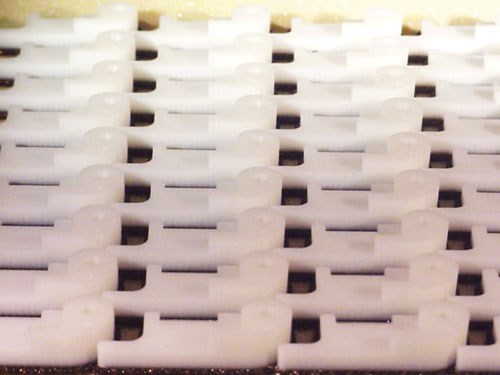

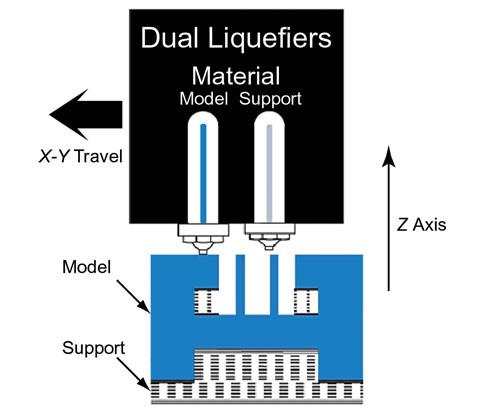

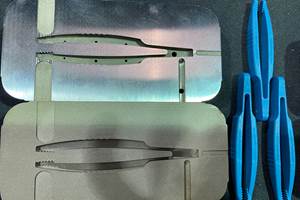

The technologies that have dominated the industry since its inception continue to remain at the fore. These include stereolithography and the new Objet technology, which is a serious contender to the stereolithography’s historical crown. Fused Deposition Modeling (FDM) has also played a significant role in the development of the industry and will continue to do so. Because of its varied material properties, FDM also plays a large role in the emerging DDM and rapid tooling markets, alongside technologies such as selective laser sintering.

In terms of future use and adoption, price pressures persist across the industry as a whole. Profitability lays in innovation and finding new ways to develop existing technologies.

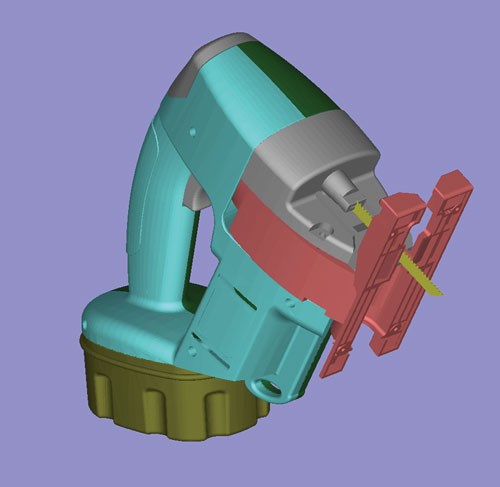

In the future, there probably will be more options in the palette and selection of materials. We are already using engineering plastics and materials in machines and can use them in extremely high temperatures. For example, we develop DDM applications for automotive under-hood components—a concept practically unthinkable 20 years ago.

DDM and tooling in their limited formats are already here and are hot topics among media and industry experts. One of the most intriguing consequences of this increase is the potential to reverse the trend to outsource manufacturing to places like the Far East in order to avoid high labor and tooling costs. This trend could potentially be reversed if companies instead purchased the DDM machines of the future, which would give them a fixed cost base, reduce labor intensity and remove high tooling costs and time, potentially negating the incentive to outsource. It would be great to see some manufacturing processes return to the developed economies.

This brief “growth chart” of the RP industry is only a snapshot. The technology is moving so quickly that it is difficult to predict exactly where people’s ideas and needs will take it. It is up to the shops to ensure that we keep up with what customers require. We also need another shift in imagination as we once again encourage companies to raise their expectations. What is certain is that the results and applications will be astonishing and exciting, and we look forward to being at the forefront of taking the industry forward.

Related Content

3D Printing Enables Mold Shop to Rapidly Prototype Medical Parts (Video)

A case study involving Mantle’s 3D printing technology allowed moldmaker Westminster Tool to go from design to injection molded prototype medical parts in three weeks.

Read MoreWhy This Photopolymer Developer Wants Prototyping to Go “Massless”

High-performance materials supplier polySpectra is embracing augmented reality (AR) with a new tool called Massless intended to reduce unnecessary 3D printing.

Read MorePowderCleanse Concept Delivers In Situ Powder Analysis for Metal 3D Printing

A collaborative project developed a prototype solution for measuring particle size distribution on the production floor, as part of the sieving step typical to additive manufacturing processes using metal powders.

Read MoreFoundry Lab: How Casting in a Day Will Improve the Design of Metal Parts (Includes Video)

The company’s digital casting process uses 3D printing, but the result is a cast part. By providing a casting faster than a foundry, the company says effective prototyping is now possible for cast parts, as well as bridge production.

Read MoreRead Next

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More