Sustainability’s Moment Is Additive Manufacturing’s Moment

The disruption needed by additive manufacturing closely mirrors that required to implement the circular economy. Both can be pursued simultaneously — and the right time is now.

In the conventional linear economy, resources are extracted, converted into goods, sold, and discarded at the end of their lifespan. While this model has worked for generations, the earth in 2020 is not in the same condition as it was even a few hundred years ago at the dawn of the Industrial Revolution. Those raw materials are no longer as plentiful as they once were, and the world’s capacity to produce trash has outstripped our ability to deal with that waste. Manufacturing and consumption cannot continue in this fashion indefinitely. In a word, the linear model is unsustainable.

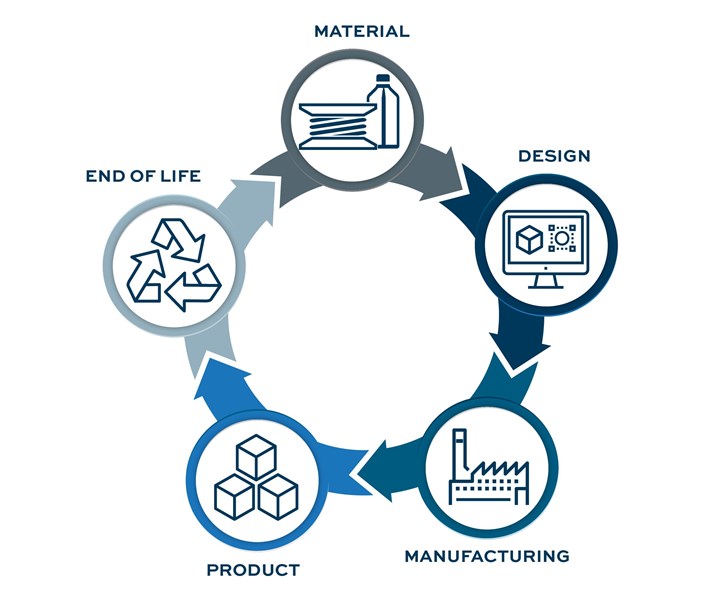

What, then, does a sustainable model look like? The term “sustainability” is often associated with recycled materials, but truly sustainable manufacturing goes far beyond this and touches every aspect of the product lifecycle. To be sustainable means to be continuous, to do things in a way that allows them to carry on for the longest amount of time possible, even perpetually. It is manufacturing that supports and enables the circular economy. This model closes the loop left open by the linear economy, connecting everything from material through end of life in a continuous cycle.

To manufacture in a circular economy means selecting materials that are renewable, whether from sustainable biological or recycled sources. It means designing parts and products to use feedstock efficiently, and limiting the diversity of materials used. It means creating products that are optimized to conserve energy and reduce emissions. It means manufacturing locally and on demand, making only what is needed near where it will be used. It means creating better products that more precisely suit the need, and therefore will have longer lifespans. It means resuming responsibility for a product at the end of its life, and designing systems to recapture, reuse, remanufacture or recycle resources back into the material stream to begin again.

The circular economy unites every step of the supply chain. Resources used as materials in the beginning of a product’s journey are recaptured and fed back into the system at the end of its usable life.

To move from a linear model to a circular one is undeniably disruptive. But the disruption needed to implement sustainable manufacturing closely resembles that required by additive manufacturing. Both demand disruption of the supply chain in terms of material, design, manufacturing, product and end-of-life. Disruption in pursuit of one is also an opportunity to pursue the other simultaneously.

When I started exploring the connection between additive manufacturing and sustainability at the beginning of 2020, disruption was voluntary. But then, a global pandemic disrupted nearly everything, throwing into relief the various problems with linear supply chains. Manufactured goods including desperately needed PPE could no longer travel easily. Certain materials in high demand, like the PETG used in face shields, could no longer be sourced reliably. Healthcare workers worldwide were asked to make do with less, to stretch supplies of what might previously have been single-use products; every respirator mask became precious. The production of critical items like ventilators was not easily scalable and slow to ramp up. Testing lagged as we struggled to shift swab manufacturing to the places it was needed most.

But in the face of these challenges there was also a silver lining: In many cases, additive manufacturing was able to step in and help, to be the stopgap measure that helped save lives. Now, as we begin to climb out of the chaotic heart of the pandemic, it is time to seek more permanent solutions. The crisis revealed that we need a model for manufacturing that is flexible and digital, that is distributed and interconnected, and that conserves resources by deploying them in the most effective ways possible.

This is the moment for additive manufacturing, and it is also the moment for sustainability.

Our July issue contains eight stories that speak to the ways that AM and sustainability are informing, advancing and enabling each other. In the print magazine (you can find the digital edition here), each of these articles is marked by the graphic you see above, with the relevant circular economy stage(s) highlighted. Many of the companies and efforts they describe are new, and unencumbered by preexisting, linear procedures. But as with AM, these early adopters are important: They point the way so that others can follow. And, we’ll be there to tell you about it.

Make sure to subscribe to keep up with all things additive manufacturing, and for more on how AM will accelerate the circular economy, see this special report.

Related Content

Multimodal Powders Bring Uniform Layers, Downstream Benefits for Metal Additive Manufacturing

A blend of particle sizes is the key to Uniformity Labs’ powders for 3D printing. The multimodal materials make greater use of the output from gas atomization while bringing productivity advantages to laser powder bed fusion and, increasingly, binder jetting.

Read MoreHow Hybrid Tooling — Part 3D Printed, Part Metal Shell — Accelerates Product Development and Sustainability for PepsiCo

The consumer products giant used to wait weeks and spend thousands on each iteration of a prototype blow mold. Now, new blow molds are available in days and cost just a few hundred dollars.

Read MoreAdditive Wins on Cost, Plus Process Monitoring and More from RAPID + TCT 2023: AM Radio #38

Additive manufacturing is finding success as a cost-effective manufacturing method. New options for process monitoring are now available. DED is getting more precise. 3D printed chairs! What we learned and observed at RAPID + TCT 2023.

Read MoreGE Additive Helps Build Large Metal 3D Printed Aerospace Part

The research is part of an initiative to develop more fuel-efficient air transport technologies as well as a strong, globally competitive aeronautical industry supply chain in Europe.

Read MoreRead Next

Additive Manufacturing Will Aid And Accelerate The Circular Economy

A circular economy links material, design, manufacturing, product and end-of-life in a continuous, sustainable loop. This special report illustrates the roles for 3D printing every step of the way.

Read MoreWhy “Recycled” Doesn’t Mean Inferior for 3D Printing Filament

GreenGate3D’s PET-G filament is made from recycled plastic, but that doesn’t diminish its quality. How a recycler found a new business opportunity in 3D printing, and how this success might point the way to a more effective recycling ecosystem.

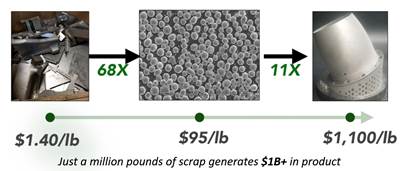

Read MoreIs Recycled Metal Scrap the Future Feedstock of Choice for Metal 3D Printing?

MolyWorks is future-proofing the circular economy for metals with small-footprint atomization technology that converts metal scrap into additive manufacturing powder on the spot. But that's not the end of the story.

Read More

.jpg;width=70;height=70;mode=crop)