We’ve already discussed how the circular economy model is additive manufacturing’s best opportunity for sustainability. But this model can be difficult to implement, and one challenge is figuring out how to go from end product back to raw material. Some companies are addressing this challenge by establishing material take-back programs, where they accept waste material and products at the end of their lifecycle, which are then broken down and recycled into material suited for use in other products. Cohost Stephanie Hendrixson and I discuss different examples of these programs on the latest episode of the AM Radio podcast. Listen above, or read on for the transcript and notes.

Transcript

Stephanie Hendrixson

Welcome to AM Radio, the show where we tune into what's really going on in additive manufacturing. I’m Stephanie Hendrixson, and today, I’m joined in the studio by Julia Hider. We have a fun show planned for you. First, we’re going to talk about material take back programs and ways that companies are creating new 3D printing materials from existing objects. Then we’re gonna shift gears to discuss ways that 3D printing is helping animals and what that has to do with industry and us humans. That’s all coming up on AM Radio.

Julia Hider

This episode of the AM Radio podcast is brought to you by PTXPO, the show for North American plastics professionals. Join Additive Manufacturing Media and sister brand Plastics Technology for the first ever edition of this event in March of 2020. To find more information at plasticstechnologyexpo.com.

Stephanie Hendrixson

Welcome to the show. Julia, thank you for being in the studio here today.

Julia Hider

I’m excited to be here.

Stephanie Hendrixson

So I understand there’s something on your mind that you didn’t talk about.

Julia Hider

Yeah, I want to start today’s episode by talking about a trend I’m noticing in additive manufacturing of companies establishing systems for recycling materials. We touched on this a little bit in the last episode with the two of us where we talked about sustainability and additive manufacturing. But I wanted to talk about these material take back programs a little bit more because I’m noticing more and more examples of them lately. Like, we just got this press release from Roboze about a circular economy system they’re launching early next year. And the idea is that customers will be able to send waste material and parts that have reached the end of their life cycle back to Roboze, and they’ll use it to produce new material and then give discounts on that material to their users, which totally fits the circular economy model you described to me in the sustainability conversation. So this got me thinking about other companies that are doing similar things. So Stephanie, do you know of any other companies that have material take back programs like this?

Stephanie Hendrixson

I do know a couple. So Roboze, I was really excited to hear about because I feel like this is a real problem, like this is the point where the circular economy idea breaks down, like what do you do with the stuff you don’t need anymore. And so it’s really interesting to see a company like that is sort of opening this up to all of their users where no matter if you have one machine, or you have a whole like fleet of 3D printers that you can take advantage of this. Most of the other ones I can think of are on, like, a higher scale. So there’s this company called Kimya. Or it’s, actually it’s part of Armor Group, which is a French company that makes different types of films and inks and like printer cartridges, and Kimya is sort of the filament brand that they’ve established within their AM group. And now they work with like large companies, like L’Oreal, that have multiple 3D printers. They’re making things like prototypes and fixtures and different things like that for the assembly lines, and once they sort of have enough of that stuff built up, Kimya will take back what they’ve accumulated, and they’ll convert it into into new filament. But I think, like, the scale issue is maybe sort of a hurdle, like I’m saying this and as I’m, as I’m talking about it, I’m thinking of this other manufacturer that’s making on a much smaller scale, like a consumer facing product, and they really, really want to be able to do that themselves. But at this point, they’re just sort of, like, collecting the used product that’s coming back and just kind of stockpiling it until they have enough to go to a processor and make it worth their while. So yeah, these take back programs, I think, are a really great thing. And I'm excited to see that expanding beyond, you know, the scale of of a company like L’Oreal that has sort of a critical mass of 3D printed stuff.

Julia Hider

Like you mentioned tooling in the Kimya example. And IC3D is another company that comes to my mind that's doing recycling for tooling. Specifically, I mentioned them in the context of them making their own printers but they also make 3D printing filament including a recycled PET G and they got into this market of making recycled PET G filament because one of their customers of their service bureau business has a real focus on sustainability and they were going through a whole bunch of plastic 3D printed tooling. I think they said the company was ordering anywhere from six to 12 of these parts per month. And it's all single use, so they need it to perform one specific task and then they don't need it anymore. And so the customer is concerned about all this waste that they were producing. So they asked IC3D about setting up material take back program where they could return this tooling to IC3D when they were done with it and then it could be recycled. So IC3D went out and bought this grinder where they throw these used parts in and other you know waste material into this grinder and it breaks everything down into small particles. And they had some big containers of this broken down material there and it looked like confetti or sprinkles. It was all different colors. It was it was pretty cool to look at. But they also got this micro blender where they mixed these broken down particles with virgin material and other additives and then they can extrude it into new recycled filament. You know, going back to the scale thing, this program is still pretty small. And they said they need to do some more work to figure out the economics and the market to see if they can scale it.

Stephanie Hendrixson

Gotcha. It's it's interesting that you mentioned PET G. I don't know why that seems to be one of the more recycled materials. But my mind just instantly went to this other company called Greengate 3D where it's not a take back program. Really, they're they're taking industrial wastes. So things that are like trimmings when you would thermoform a part, or just excess material that can't be used. And so they take all this industrial PET G waste, and they convert it into a filament as well. You know, I don't know that they would ever get to the point of like taking back prints that people have made. But like, that's just another another case of that same material. Finding a different use after it's kind of original purpose is over.

Julia Hider

So we've talked about all plastic examples so far. Do you have any examples of metal material being recycled?

Stephanie Hendrixson

Yeah, I'm not sure, you know, like what scale this is happening on right now. But one example that comes to mind is a story that just came out on our website about 6K Additive, they have this sort of two step process for making metal powders. The first step is to take whatever metal you're going to start with and grind it down to the size that you need it to be. So like mechanically milling it down to the right grain size. And that starting material could be anything, basically, it could be machining chips, it could be oversized powder from the gas atomization process, it could be extra parts that you don't need anymore. And so they they figured out ways of cleaning that material, processing it down to the right size. And then the next step in the process is they put everything through a microwave plasma reactor. So they take all that material that is the right size already, but it's like weird, wonky shapes, and drop it through this pillar of plasma, which melted just enough to like densify the material, make all those little particles into little spheres, and then it comes out of the reactor, and it's ready to go into additive manufacturing. So by separating the sizing from the shaping, they're able to really expand the types of feedstock they can put through this process.

Julia Hider

Yeah, I visited their booth at Rapid and I thought it was so interesting, especially coming from a background of writing about metalworking, and you go into the shops, and outside of every machine, there is a giant bin of chips. And when you're machining a part, you could be machining 90% of the stock away and turning it into chips. And so it's really cool to think that those chips could become additive manufacturing feedstock.

Stephanie Hendrixson

Yeah, then there's also kind of like a supply chain aspect to 6K as well, because you know, things like titanium, we don't have a good domestic source for that material. Most of it's imported if it's, if it's virgin stock, but like you said, every machine shop has these bins of chips sitting around. And so there's all this material, maybe locally that could be turned into something else. 6K sees a scenario where maybe like key customers would have one of these reactors on site. So that if they're getting spare parts back, or things get broken, or they just have like lots of chips accumulating, they could process their own material that kind of reminds me of a different company that we covered recently called Metal Powder Works. So this is a company that was co founded by John Barnes, of the Barnes Global Advisors, he's contributed to Additive Manufacturing a couple of times, very well known in the industry. And what they've developed is a purely mechanical process for making metal powder. So you could take something like barstock and put it through this system, and it would just very precisely chip off the right size powder particles from whatever solid piece of material that you have. They're talking a lot about, you know, the ability to use barstock because it's a very stable material. It's not like handling metal powder. It's not something that's a fire hazard to store, it's not sensitive to moisture and and all that. But really the feedstock for this process could be anything, it could be spare parts, it could be legacy materials, it could be you get a bunch of chips together and clean them and melt them down into it or something that you could use for this process. And that again is something that they see being applicable on site even like expeditionary manufacturing, they're working with Speed 3D and the Australian military right now to see if this could be applied just out in the field somewhere where you're not in civilization at all.

Julia Hider

Exactly. IC3D, going back to the plastic example, IC3D had mentioned making this into a system for customers as well.

Alright, I think that's a good wrapping up point for this conversation. Stay tuned after the break because there will be cute animals.

Stephanie Hendrixson

There will indeed.

Related Content

Sustainable Metal Powder Company Addresses Next Piece of Road Map: Renewable Energy

Continuum Powders, the material production arm of small-scale foundry technology company MolyWorks, has announced new partnerships aimed at further reducing the environmental impact of its metal powder production.

Read MoreSculpteo Offers RE-cycleo 3D Printed Part Recycling Program

The program offers recycling services to Sculpteo clients not only for the clients’ obsolete parts but also for production scrap.

Read More6K Additive Receives Sustainability Award

The Additive Manufacturing Green Trade Association (AMGTA) presented the Environmental Sustainability Research Award to 6K Additive based on its UniMelt powder manufacturing process.

Read MoreCastor Publishes Sustainability in Additive Manufacturing Trends Report

New research from Castor indicates manufacturers can reduce tons of carbon emissions with 3D printing.

Read MoreRead Next

A Circular Economy for 3D Printed Plastics Starts with Material

When the greatest share of a product’s environmental impact comes from producing its feedstock, selecting the right material is critical. For 3D printing and manufacturing in plastic, biopolymer could be the first step toward a more sustainable model.

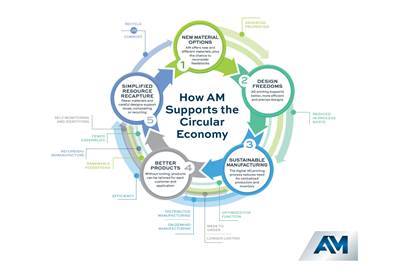

Read MoreInfographic: How Additive Manufacturing Supports the Circular Economy

This downloadable infographic illustrates how 3D printing can be applied for more sustainable manufacturing through every stage: Material, Design, Manufacturing, Product and End-of-Life.

Read MoreHow Is Additive Manufacturing Sustainable? AM Radio #2B

Additive manufacturing is often closely associated with sustainability, but why? And how can companies use AM to develop sustainable processes? Stephanie Hendrixson and Julia Hider discuss in this episode of AM Radio.

Read More