Postprocessing Composite Tooling: Machining, Coating or Combination Strategy?

A project testing the surface finishing options for composite tooling reveals insight about machining and coating strategies.

It’s been said that tooling is the lowest hanging fruit for applying additive manufacturing. At the most recent Additive Manufacturing Conference, Zeke Sudbury of Cincinnati Inc. painted a picture of how to grab that fruit when it comes to big area additive manufacturing (BAAM) in composite tooling.

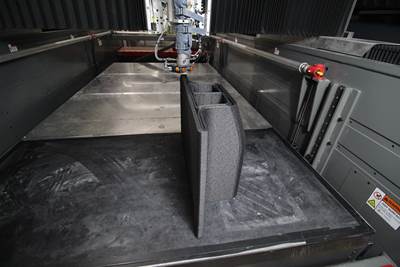

BAAM is a large scale, industrial approach to AM, but at its core is just an FDM machine with a build area of 8 feet wide by 20 feet long by 6 feet high (2.5 by 6 by 2 meters). The system has a bead diameter of ¼ inch and offers speeds of 80 pounds (40 kg) per hour and 10 to 20 inches (250-500 mm) per second using inexpensive pelletized feedstock in an open material platform. What makes BAAM unique is that it can use filled polymers, such as ABS filled with carbon or glass fibers.

This capability and the system’s size make it suitable for producing fiber-reinforced tools for composite molding. A fiber-reinforced composite tool consists of a mold topped with a protective surface coating followed by a mold release and then a fiberglass composite on top. Composite tools are typically very slow to produce, but BAAM makes it possible to print the tool in one day. Essentially, the system enables skipping the “plug” step of traditional composite tooling.

However, to assess BAAM for composite tooling means determining the proper surface finishing strategy. Although most AM processes require some form of postprocessing, the challenge is greater with BAAM due to its large bead diameter. A finishing strategy for BAAM parts could be machining, coating or a coating/machining combination. Sudbury shared the results of studies conducted in cooperation with University of Tennessee, Oak Ridge National Laboratory, Manufacturing Demonstration Facility and the U.S. Department of Energy to help determine the optimal surface finishing option.

To test the surface finishing options, the team created two sets of test molds: a hexagon mold to test coatings on a variety of flat surfaces, and a geometrically complex shape to test machining on a variety of surfaces. Two of each test mold were printed in two different orientations to observe the effect. Initial test results indicated that the coated tools lasted four pulls and failed because the coating debonded from the part. Machined molds lasted five pulls before the heat from the resin caused the mold to degrade.

To improve results, the next round used a specialized coating that bonds to ABS, applied vacuum assisted resin transfer molding (VARTM), matched coefficient of thermal (CTE) expansion of ABS and used self-leveling to reduce hand labor. On the machining side, researchers switched to a thermoplastic with a higher glass transition temperature and ketone-resistance for cleaning, and a low CTE for autoclave environments.

The second round noted improvements in both the coated and machined tools, but the team believes the industry is headed toward a combination coating/machining strategy. This entails printing a mold, coating it and then machining it to tolerance. For example, Sudbury cited a windmill turbine mold (pictured above) that takes six months to a year to produce traditionally, but took BAAM only two weeks. The 3D-printed tool was both coated for VARTM and machined to tolerance.

Related Content

World’s Largest Metal 3D Printer Seen at Ingersoll Grand Opening Event

Maker of large additive and subtractive machines adds capacity in Rockford, Illinois.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreNext-Gen Horse Trailers to Be Built With Robotic 3D Printing

Double D Trailers is currently developing a prototype horse trailer that will be made with large-format additive manufacturing. The technology brings potential benefits for labor, weight and design features to this subset of recreational vehicles.

Read More“Mantis” AM System for Spacecraft Uses Induction for Deposition

The metal 3D printing system melts wire without lasers. 30-foot-diameter parts are built on a rotary-feed system that eliminates the need for a large machine frame or gantry.

Read MoreRead Next

3D Printing Autoclavable Composite Molds

A polymer AM research team at ORNL reports it has successfully fabricated autoclave-capable carbon fiber composite molds, manufactured using large-scale 3D printing/additive manufacturing.

Read MoreOhio Business Sees Big Possibilities in BAAM for Tooling

A new startup built around a large-scale 3D printer aims to offer short lead times for large industrial tools.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More