Panel Discusses Promise and Challenges of Both Additive and Hybrid Machines

Manufacturers ranging from orbital to underground shared their thoughts on additive manufacturing at the recent Innovation Days event.

Share

Read Next

The machine coming soon integrates additive manufacturing into a turning and milling machine accommodating parts ranging to 26 inches diameter.

At DMG MORI’s recent “Innovation Days” event in Hoffman Estates, Illinois, one of the more than 30 machine tools the company featured was a prototype of the new Lasertec 4300 3D additive manufacturing machine to be released later this year. This hybrid machine—the second hybrid from the company—integrates additive manufacturing capability into a machine capable of turning and milling parts ranging to 26 inches in diameter and 59.1 inches long.

The event also included a panel discussion with representatives of companies using or exploring additive manufacturing. On the panel were representatives of NASA and Virgin Galactic, as well P Tooling and Global Innovations, both of which are involved in mining or oil and gas drilling.

P Tooling is a machining business based in Amherstburg, Ontario, serving the oil industry. Company president Marv Fieberg described the various benefits he expects to realize from additive manufacturing. They include:

- Flanges. To produce a part with a flange, the shop’s approach today is to begin with a workpiece much larger than the finished part and machine it down so that the flange is revealed. With so much metal reduced to chips, it can sometimes seem to him as though “only the steel supplier makes money,” he says. Adding the flange (as opposed to machining away everything that’s not a flange) will provide a more efficient approach.

- Complexity. Parts holding instrumentation for directional drilling can be intricate, he says. Additive manufacturing will provide a simple way to make these complex forms.

- Inconel. With additive manufacturing, the expensive alloy can be applied sparingly, he says. For example, Inconel can be used to clad or build just the critical features of a part that is otherwise made from a much less costly metal.

- Diversification. It is a given among oilfield manufacturers that the oilfield industry is not always a lucrative sector to serve. By acquiring expertise at additive manufacturing, Mr. Fieberg hopes his shop can become a supplier to the aerospace sector as well.

Speaking from that sector, Virgin Galactic combustion devices manager Mauritz deRidder and propulsion production engineer Kevin Zagorski described the value their company sees in additive. Part of that value is in consolidating assemblies, they say—saving effort and saving weight by redesigning subassemblies into complex single pieces that can be additively grown. However, “there is no single killer app,” Mr. Zagorski says. Rather, there are so many potential applications for additive that the company “can’t afford to not pay attention to it.”

But Mr. deRidder points out the challenges. There are several. For example, additive manufacturing can grow complex internal features, but how do manufacturers then inspect those features? How can the geometry and finish of features deep inside of a part be validated? The answer to that question will somehow have to be found, he says, before additive parts with critical internal geometry can enter production.

Certain other challenges are being addressed. Established metal additive manufacturing machines are relatively slow and capable of making only small parts, he notes, but the hybrid machine concept—metalcutting machine tools with additive capability, such as those from DMG MORI—addresses both of these problems. On a CNC machine tool, both the speed and the size of additive manufacturing can more practically be scaled up.

Yet he points out that hybrid machines do introduce a challenge relative to the established additive manufacturing systems. On a system such as a powder bed machine, it is an easy matter to grow test coupons along with the part to validate the material properties. But on a hybrid machine tool laying down material using an additive head, producing test coupons would require additional machine motion and cycle time. Finding the most efficient way to validate material is another detail he says Virgin Galatic, and other companies aiming to make end-use parts additively, will have to work out if they adopt a hybrid approach.

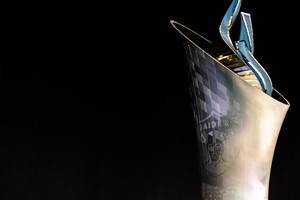

The new machine will apply additive manufacturing using a metal deposition system like that of the company’s Lasertec 65 3D hybrid machining center, seen here.

Related Content

The World’s Tallest Freestanding 3D Printed Structure

Dimensional Innovations paired additive and subtractive manufacturing to create a monument for the NFL’s Las Vegas Raiders new stadium. The “never been done before” project resulted in the world’s tallest freestanding 3D printed structure.

Read More8 Cool Parts From RAPID+TCT 2022: The Cool Parts Show #46

AM parts for applications from automotive to aircraft to furniture, in materials including ceramic, foam, metal and copper-coated polymer.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreAirless Basketball Shows Promise of 3D Printed Lattices: The Cool Parts Show Bonus

Successfully matching the performance of a standard basketball demonstrates the control possible over the mechanical properties of digital materials.

Read MoreRead Next

At General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More

.jpg;width=70;height=70;mode=crop)