Metal AM: Is Welding the Way In?

Optomec’s machine tool for metal 3D printing is also an accessible system for automated welding. The embrace of one use of this machine might lead to increasing exploration of the other.

Share

Read Next

Additive manufacturing as a means of making metal parts is a new possibility for many production facilities. Meanwhile, welding is a metalworking operation that is commonplace, well-established and widely employed.

Yet aren’t these overlapping practices?

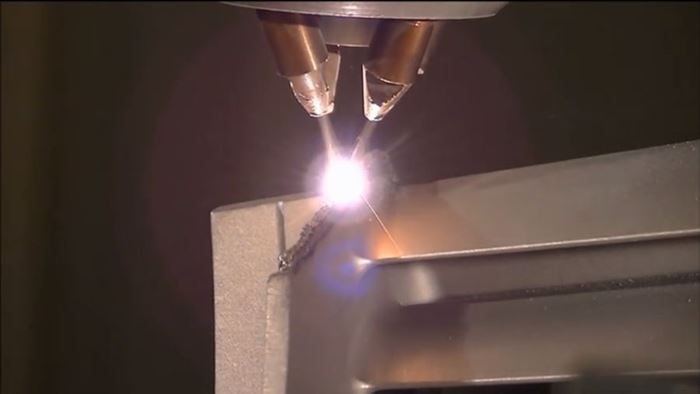

In the case of metal AM via direct material deposition, they certainly are. Welding consists of adding a layer of molten metal to the work, often for repair of an existing part. Direct-deposition AM also consists of adding a layer of molten metal to the work—and then another layer and another atop that—in order to build up a three-dimensional form or feature. A direct-deposition metal AM system therefore could be used for some welding applications, and if the system is inexpensive enough, then this might even be its primary use and justification.

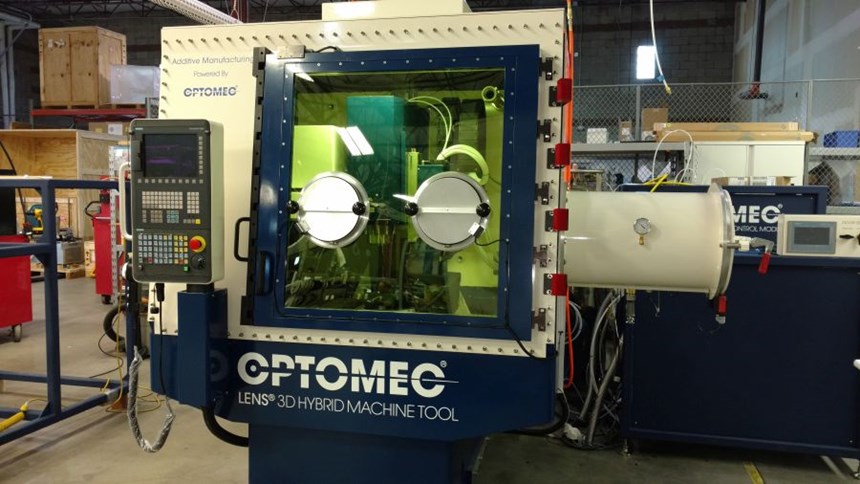

David Ramahi, president and CEO of Optomec, says his company is becoming increasingly aware of the importance of this potential use of its metal-deposition equipment. Last year, the company introduced a standard product consisting of its Laser Engineered Net Shaping (LENS) metal AM technology integrated into a standard vertical machining center. The result is a metal 3D-printing system available for about $250,000, he says, with milling capability also available in this same machine for about 10 percent more. But at that relatively low price, says Ramahi, 3D printing does not necessarily have to be the point of the machine. Where the purpose of welding is repair, or resurfacing parts to put them back into service, the machine could offer a solution for that need.

Skilled welders are becoming difficult to find, he notes. As is the case with various industrial trades, welders today are nearing retirement in greater numbers than new people are entering the field. Therefore, while replacing manual welding in some cases with automated welding on a CNC machine tool might be a leap for many facilities, it is a leap that can address an otherwise challenging personnel problem. Indeed, given that these facilities likely already have CNC machining centers, and given that widely-used software including Mastercam and Powermill has already been adapted to program the LENS machine, this choice might represent the leap into automated welding that is easiest for them to make. Along the way, it might also extend the range of repairs welding can peform, because—different from MIG or TIG welding—LENS is a targeted deposition process allowing for repair of thin walls and other delicate features with minimal heat effect.

The annual value of welding overall in industrial production is about $20 billion, Ramahi says. Welding for repair represents a share of that, but it is a share he beleives is on par with welding for joining. Thus, the annual value of repair-related welding is far greater than the current annual value of industrial 3D printing. But in the scenario he foresees, the use of one might lead to increased use of the other. Welding might be part of the way for AM to find its applications and advance into its ultimate promise. For the facility that has justified a metal AM machine simply for welding, using that same machine to 3D print features onto existing parts, or 3D print complete parts, represents a natural next step that the machine is just waiting for that user to take.

Related Content

AM 101: What is Ultrasonic Additive Manufacturing?

Going from additive to subtractive can be simple with Ultrasonic Additive Manufacturing (UAM). What is it and how does it work? Learn the basics in this 101 post.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreWorld’s Largest Metal 3D Printer Seen at Ingersoll Grand Opening Event

Maker of large additive and subtractive machines adds capacity in Rockford, Illinois.

Read MoreAM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

Read MoreRead Next

4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More