Medical Benefits

Part examples from an established manufacturer of medical implants and instruments illustrate the expanded engineering possibilities that additive manufacturing is making possible.

The parts below illustrate how additive manufacturing helps improve the design of medical components. The metal parts in these images were all produced by Innovative Medical Device Solutions (IMDS) via direct metal laser sintering. Learn more about IMDS in this article.

Digital Porosity

Implants such as these acetubular cups have a porous surface layer for “osseointegration,” or for the patient’s bone to grip by growing into it. In the past, adding this porous layer has involved a special step such as plasma spray. But an additive process allows the intricate layer to be made with the rest of the part, bringing advantages that go beyond just simplifying production. For example, the additive part can be designed to transition to the porous layer gradually, improving the integration with bone. In addition, the part’s structural strength can be augmented with features that plasma spray would have precluded, such as the ribs seen in the implant on the right. Michael Siemer, additive manufacturing engineering manager with IMDS, says software from companies such as Netfabb or Within Technologies can be used to digitally design this complex organic geometry. Software such as this generates complex forms from user-defined boundary conditions.

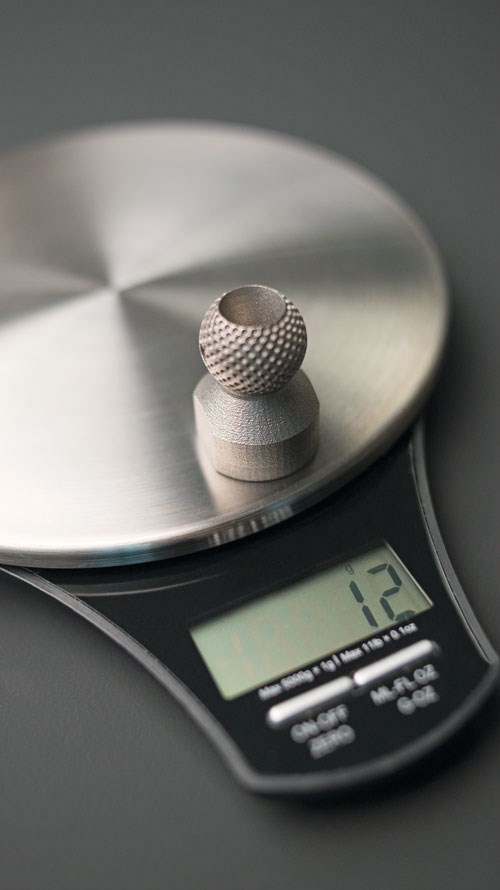

Hollow Victory

Part weight, a critical factor in aircraft or automobile parts, is an important detail of medical parts as well. Patients carry implants within them, and surgeons need to manipulate medical implements easily and comfortably. The medical part seen here would have been much heavier if the part had been machined, but the additive process enabled it to be grown hollow for weight savings. The part even has through-holes from the OD to the ID, but the hollow spaces inside the part’s walls are still airtight. The through-holes were simply grown into the component as part of the additive process.

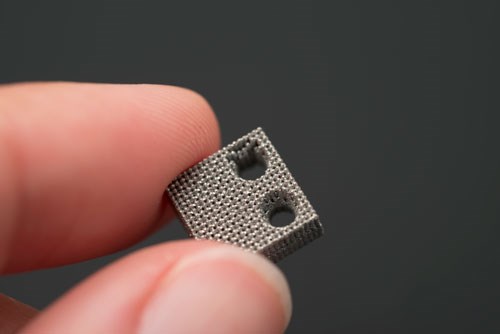

Polyaxial Locking

Surgical screws fasten bone sections together by locking into a plate. Typically, the screw has a set of threads at its head for mating to this plate. Because surgery is a manual process, the threaded hole in the plate should allow the surgeon some degree of play in the direction of this screw. Seen here is a plate concept that maximizes this play. Produced additively, this part features an engineered mesh form that finds, guides and locks the screw head across a broad range of angles, maximizing the surgeon’s hope of finding the ideal angle of attachment during the procedure.

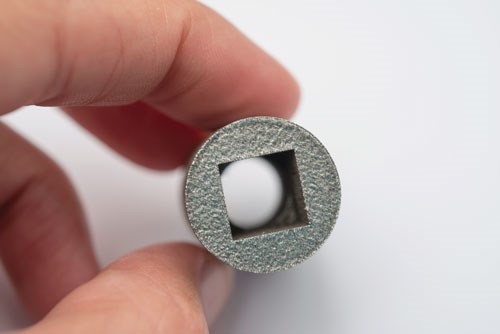

Can Your Drill Do This?

This demo part illustrates one of the most important freedoms additive manufacturing provides: the freedom to control and tailor hole profiles. No drill could decide halfway through the hole to start cutting a square hole instead of a round one, but this effect is easy to achieve with an additive process. Internal channels that are winding instead of straight are easily possible as well.

Zero In On Design

Dozens of variations of this orthodontic part were produced before the design was finalized. The creators were experimenting to get just the right form for optimal fit and functionality. Producing the complex part through this many iterations would have been impractical if molding or machining had been used, but additive manufacturing provided a natural way to refine the product. Siemer says that though this part might be made additively in full production, the quantity is still unclear, so IMDS has designed it to preserve production options. The design avoids undercuts so that metal injection molding remains a possibility.

Additive on Additive

This additively manufactured metal part receives finish milling for dimensional tolerance and finish. The fixture that holds the part for machining was also made additively (using a 3D printer). The part is a sternal closure—essentially a buckle for closing the rib cage after surgery. Its locking mechanism relies on the slots arrayed around the part’s inner circle, and these slots are angled rather than square with the part. Thus, the part’s geometry is 3D rather than 2D, making it too complex to be made through a cutting process such as wire EDM. Siemer says the angled features achieve a lock so secure that an assembled closure mechanism would be needed to match it. In short, if not for additive manufacturing, this component would need to be several pieces instead of just one piece.

Related Content

Production AM Demands Process and Procedures — More Machines Will Come Later

Arch Additive has transitioned to full production of implants made through electron beam melting. The transition has involved practices and personnel, not equipment. As customer products win approval and go to market, here are 5 operational moves the AM implant manufacturer has made.

Read MoreNew Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreView From My Shop: 3D Printing and Postprocessing With Tangible Solutions

Collaboration between Tangible Solutions’ additive and machining departments simplifies their work. Learn more in this episode of The View From My Shop.

Read MoreGE Additive, Orchid Collaborate on 3D Printing Orthopedic Joint Implants

The agreement bolsters the use of additive manufacturing in the medical implants sector with the development of electron beam melting solutions.

Read MoreRead Next

Something More

The integration of manufacturing with product development creates a context that will help additive manufacturing advance.

Read MoreSomething More

The integration of manufacturing with product development creates a context that will help additive manufacturing advance.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More

.jpg;width=70;height=70;mode=crop)