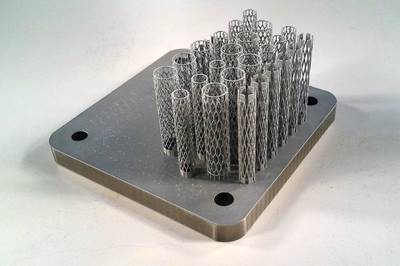

Producing parts with complex geometry — intricate forms that could not be made any other way — is one of the important benefits of using additive manufacturing (AM). Making and delivering parts within dramatically reduced lead times is another.

However, complexity and lead time might not be AM’s biggest benefits, and the advance of 3D printed surgical implants is showing this.

Lately, we have been exploring implant manufacturing. A series of recently posted articles (all linked within the final three paragraphs below) look at how 3D printing is changing, or potentially changing, the way implants are made. Yet we planned and wrote this series not for the medical industry, but for all manufacturers. Medical implant makers were among the very earliest adopters of AM for production, and now they are showing us where AM is headed. Complex geometry provides a natural fit for implants, literally, because surface complexity attainable via 3D printing encourages the patient’s natural bone to grow in and fuse with the artificial replacement. However, additive manufacturing will take implants, and all of manufacturing, even farther than the complexity win.

Amplify Additive CEO Brian McLaughlin (left) speaks with me during my visit to the company’s implant production facility in Scarborough, Maine. Read the article. Photo Credit: Amplify Additive

Here are potentially the truly transformative wins of AM: (1) material freedom, through the chance to take advantage of materials and material properties out of reach of conventional production, and (2) measurement freedom, meaning the chance to measure exactly what the application requires and use this measurement in ways that conventional hard-tooled processes don’t allow, producing a unique part tailored to the need.

Start with the first of these. Material freedom is a different kind of design freedom, the more powerful kind. Geometric freedom can accomplish a lot; complex designs for manufactured parts can reduce weight, reduce assembly and (as in the case of the bone growth) improve functionality. And achieving this geometry without any need for tooling is what permits the shortened lead time.

But materials will do still more. Materials now present the next obstacle and next opportunity on the way to realizing additive’s potential. The first step is to ensure 3D printing can work with materials already proven effective; 3D printing with nitinol offers an example. Then, AM will be key to applying even better materials than what were possible for their applications before. Examples include ceramics for reconstructive implants in place of metal, and plastic for stents used in the eye, also in place of metal.

From there, measurement will make production manufacturing responsive. I mentioned the lack of tooling in AM. What this also means is the freedom from any hard, fixed geometry that is the same from part to part. We are already seeing this freedom to vary the geometry of parts from one piece to the next being applied to make tailor-made consumer items, but the implant industry will lead the way into applying this freedom to items with much higher value — parts that preserve the patient’s quality of life or maybe even the patient’s life. Today, an individual patient might receive a custom implant made via AM, but making this customization routine comes next, and that will simply require a different kind of system — a different workflow — that makes individual measurements part of the input to production.

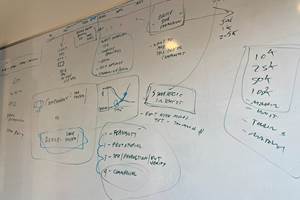

For now, there is geometry and lead time. These benefits alone offer big wins, and the task today is to advance into production on the basis of the opportunities these wins bring. Amplify Additive, an orthopedic implant startup we recently profiled, is doing just that. But read closely, and you will notice that the team at Amplify is already looking ahead to these farther-reaching benefits as well.

Related Content

3D Printing as a New Product Launchpad

With 3D printing, Minnesota manufacturer Resolution Medical offers a fast, affordable route for individuals and small to medium-sized businesses to get new medical devices and other products off the ground and into the marketplace.

Read MoreDurable, Waterproof 3D Printed Casts: The Cool Parts Show #58

Recovering from an injury with an ActivArmor cast means that patients can exercise, bathe and live life while they heal. We get a firsthand look at the solution in this episode of The Cool Parts Show.

Read MoreFDA-Approved Spine Implant Made with PEEK: The Cool Parts Show #63

Curiteva now manufactures these cervical spine implants using an unusual 3D printing method: fused strand deposition. Learn how the process works and why it’s a good pairing with PEEK in this episode of The Cool Parts Show.

Read MoreFormlabs Part Removal Mechanism Enables Lights-Out Production

A build platform overcoming the need for manual part removal enables automated part handling, and therefore continuous production from one build cycle to the next.

Read MoreRead Next

How a 3D-Printed Metal Ankle Implant Replaces an Entire Bone

Through a novel surgery involving a 3D-printed talus bone, surgeons at the University of Miami found success — and unexpected challenges — with a patient suffering from sickle cell disease.

Read MoreFor EBM Implant Manufacturer, Growth Is Built into the Plan

Amplify Additive needs to be small today. A close, nimble team can innovate quickly and realize the promise of additive manufacturing for orthopedic implants. Yet the company needs to be bigger soon, because success will lead to scalable production.

Read More3D Printed Nitinol Opens New Possibilities for Arterial Stents

Researchers at Australia’s national science agency, CSIRO, have created the first self-expanding nitinol stents made via powder bed fusion. The project points to more opportunities with this shape memory alloy.

Read More