Material Freedom

A maker of engineered plastic components applies a 3D printer that uses the same granulate as molding machines.

Share

Read Next

If there is a battle of materials in bearings manufacturing, then Igus, the Cologne, Germany-based polymer bearing manufacturer is on team plastics. As opposed to most other bearings makers, Igus focuses exclusively on high-performance plastics for motion in industrial applications (what the company calls “motion plastics”). One of the distinctive aspects of Igus’s bearings is that they are self-lubricating and corrosion-resistant.

The company completes about 2 billion test cycles annually and has more than 200,000 end users around the globe. Tom Krause, product manager for Igus, says it started working with 3D printing in 2012 as a way to offer customers even more freedom in product design compared to making parts through molding. “We want to use the advantage of 3D printing to print parts that are complex to produce,” he says. 3D printing also allows for cost-effective production of unique parts or small series. Parts the company has made in this way include not only components for bearings, but also other parts where friction and wear are important, such as drive nuts or gears. The company even develops its own materials for these 3D printing applications.

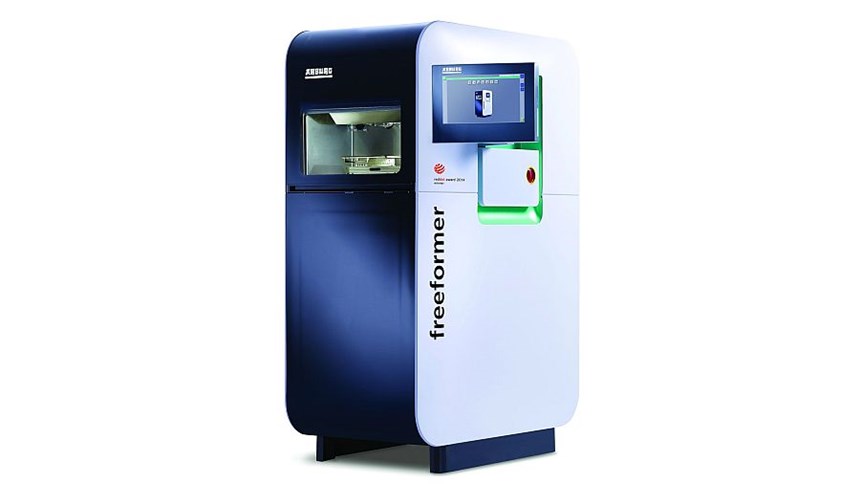

Particularly in light of this involvement in materials for 3D printing, Igus observed with interest a product introduction at the K Show in Düsseldorf, Germany, said to be the world’s largest trade fair for the plastics industry. At the 2013 event, injection molding machine maker Arburg introduced its Freeformer additive manufacturing system, which produces fully functional plastic parts without a mold from the same standard granulates used in injection molding. In this machine’s process—called AKF, the initials in German for Arburg Plastic Freeforming—standard granulates are melted in the same way they would be in an injection molding machine.

The AKF process makes use of 3D CAD files, which are read directly by the Freeformer. A nozzle closure with piezo technology then builds up the desired component layer by layer from plastic droplets to produce a three-dimensional part matching the CAD model. To create this geometry, the part under construction is moved under the nozzle by a component carrier with three or five axes.

Igus began to use the Freeformer in February 2015. Since then, it has put about 1,500 hours on the machine, the company says. Being able to use the same raw plastic as in most other plastic processing machines is a big advantage, says Krause. With the Freeformer, the company can use and try out a wider variety of plastics than with other printers.

“This raw material is much cheaper than the usual printing materials because with other printers, you need to have the plastic in a very special ‘shape,’ which makes it more expensive,” he says.

Thus far on the Freeformer, Igus has printed bearings, gears, sliders, drive-nuts and drive-screws. It has used both standard plastic granulates as well as its own 3D printing materials in the machine.

Krause says a big advantage of 3D printing in general is the ability to bypass expensive tooling for prototypes. The company can create new parts this way “much faster and more cost-effectively” than it could with previous prototyping methods. Some of the part geometries made this way are candidates for traditional molding. But, Igus also sometimes uses 3D printing to make parts that can’t be produced in any other way.

Related Content

How Large-Format 3D Printing Supports Micro-Scale Hydropower

There is potential hydroelectric power that has never been unlocked because of the difficulty in capturing it. At Cadens, additive manufacturing is the key to customizing micro-scale water turbine systems to generate electricity from smaller dams and waterways.

Read MoreWhat Does Additive Manufacturing Readiness Look Like?

The promise of distributed manufacturing is alluring, but to get there AM first needs to master scale production. GKN Additive’s Michigan facility illustrates what the journey might look like.

Read MoreLarge-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

Read More8 Cool Parts From RAPID+TCT 2022: The Cool Parts Show #46

AM parts for applications from automotive to aircraft to furniture, in materials including ceramic, foam, metal and copper-coated polymer.

Read MoreRead Next

4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More