Manufacturing to Meet Tech Community at MT360

I will hold onstage conversations with additive manufacturing and collaborative automation leaders as part of the new technology event to premier May 12-14, 2020 in Santa Clara, California.

Update: MT360 has been rescheduled to May 12-14, 2020. The column below has been revised to reflect the new dates. The speaker lineup is expected to remain the same. Save the date for the launch of this new tech-meets-manufacturing event.

Is there a connection between the “tech” culture we associate with Silicon Valley and the industrial culture at work in manufacturing facilities throughout the rest of the country?

Seemingly yes, and that connection is growing stronger. Today, the manufacturing technology developments offering the most promise to dramatically transform manufacturing tend to be digital, including artificial intelligence (AI), collaborative automation, the Internet of Things (IoT) and additive manufacturing (AM). To varying degrees, these technologies leverage tech community advances that are still advancing. Indeed, the latest tech innovations may find their greatest impact in the potential they offer to accelerate, streamline and reorder the ways that things are made.

ThyssenKrupp Bilstein’s plant in Hamilton, Ohio, (far from Silicon Valley) exemplifies this. This established manufacturing facility makes a familiar product, shock absorbers. Yet as this this article describes, the addition of a seemingly small new technology is having an unexpected effect on the possibilities for this plant. At Bilstein, collaborative robots were supposed to be beneficial in just a few areas where automation needed to be near people. But the technology proved such an effective option for versatile, redeployable automation that the company found other applications in which proximity to people was not even a requirement. Furthermore, this success led directly to the application of another versatile automation system: autonomous intelligent vehicles capable of various tasks throughout the facility. At Bilstein, digital-enabled technology is changing the very paradigm for automation within the plant.

Which is why Bilstein CEO Fabian Schmahl is traveling to Silicon Valley next month. I am going there, too. Onstage at the new MT360 event, I will chat with Schmahl and others about the changing face of manufacturing technology.

Organized by AMT–The Association For Manufacturing Technology, MT360 is an event aimed at bringing together manufacturing leaders and the tech community. The event is May 12-14, 2020 in Santa Clara, California. The plan for the event is itself innovative—sort of a conference, sort of a trade show, and more than both. The conference program includes not only the in-depth conversations I will have with technology leaders in additive manufacturing (from EOS and HP) and collaborative automation (from Bilstein and Veo Robotics), but also concise presentations from up-and-coming users and providers of AM, AI, IoT and other digital manufacturing technologies, including little-known startups. Alongside this program, the complement and equal companion to these speakers will be the event’s Virtual Factory, the “show” part of the show-and-tell format, offering hands-on demonstrations of disruptive digital technologies at work in a simulated manufacturing setting.

Attendance is limited—the hope of direct networking between tech and manufacturing leaders is one of the event’s aims. Indeed, the insight underlying the event is the recognition that tech and manufacturing should not be such separate cultures any longer. Learn more about MT360 and register to attend at mt360conference.com.

This article originally appeared on Modern Machine Shop.

Related Content

How AM Enables Cobot Automation for Thyssenkrupp Bilstein (Includes Video)

The shock absorber maker has responded to its staffing shortages through extensive use of collaborative robots. In-house 3D printing makes this possible by providing the related hardware needed to complete the cobot-automated cells.

Read More10 Important Developments in Additive Manufacturing Seen at Formnext 2022 (Includes Video)

The leading trade show dedicated to the advance of industrial 3D printing returned to the scale and energy not seen since before the pandemic. More ceramics, fewer supports structures and finding opportunities in wavelengths — these are just some of the AM advances notable at the show this year.

Read MoreFormlabs Part Removal Mechanism Enables Lights-Out Production

A build platform overcoming the need for manual part removal enables automated part handling, and therefore continuous production from one build cycle to the next.

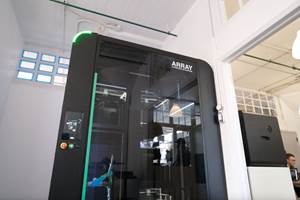

Read MoreMosaic Array — Automated Print Farm with Machine Tending and More

Mosaic’s Array additive manufacturing system combines multiple forms of automation, including machine tending, material management and scheduling, to enable unattended production.

Read MoreRead Next

Video: HP on Additive Manufacturing for Production

HP’s Timothy Weber discusses VW’s plans for making metal parts via AM and the way forward to implementing additive as a production process.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More