In our first article in this three-part series, we explored the potential benefits of using multi-laser powder bed fusion (PBF) systems considering bed size and therefore part production, laser power and parameters. We then compared that to another form of AM, binder jet processing, where we looked specifically at print speed, effective print speed, and actual part cost. In this third article, we will bring it home with a look at the overall investment, impact of throughput and the output of multi-laser powder bed fusion systems. What implications are there in using a multi-laser system? Once again, we will use a data driven approach.

“Life moves pretty fast. If you don’t stop and take a look around, you could miss it.” —Ferris Bueller. This statement is perhaps truer in 2021 than it was in 1986. Since our first article in this series, three new machines have been introduced with laser counts of 9, 10 and 12. After the first two articles, we are all astute enough to ask good questions like: Is more better? Is print speed everything? What if we take a hard look at what it takes to be successful in the AM parts making business?

Meeting the Requirements

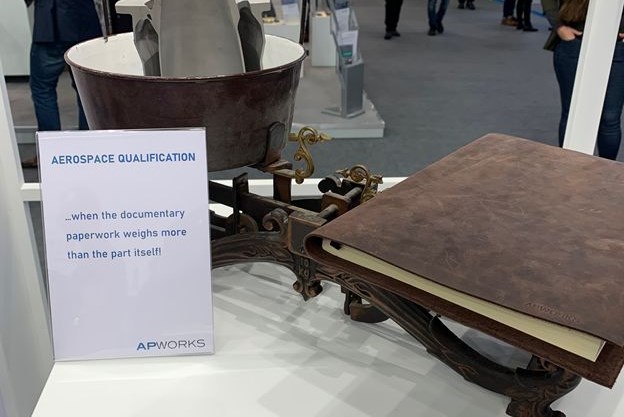

Making production parts is hard. Make no mistake, meeting all of the requirements put on you is very difficult. It’s more than making a shape. I took this snap at the APWorks booth at Formnext in 2019. They whimsically portray the weight of the documentation to make aerospace parts next to the weight of the actual parts. Whilst I enjoy some dry English humor, I also appreciated the weight of the point they were making (see what I did there?). A wise man once told me, “Manufacturing needs to learn about AM, but AM needs to learn a lot more about manufacturing” (R. Resnick).

Figure 1: A dry look at aerospace part manufacturing.

Understanding the Business Case

When running a contract manufacturing business, buying the latest equipment every year really is not an option. Productivity (yes, you knew it was coming), is critically important. Multi-laser systems can produce parts faster, but the equipment is also more expensive; the key is to be more productive (i.e. turn out more product per unit cost). There is an important reason an entire section of our TBGA AM training courses is focused on business case and process economics; we must appreciate the role of cost drivers.

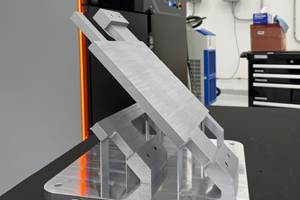

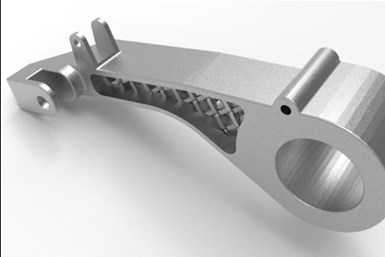

Figure 2: The TBGA control arm is a sample part weighing about 1 kg that can be successfully 3D printed with either PBF or binder jet. (For a comparison of these processes in terms of speed and cost in producing this part, see Part Two of this series.)

The main cost driver in the TBGA control arm made by PBF is the 3D printing versus the materials and processing completed after printing. A key driver within that printing cost is the depreciation of the 3D printer itself. Depreciation essentially allows a business to take the cost of the equipment and spread it over the useful life, giving you a true cost of operation in a $/hr figure. When you are in series production, the $/hr goes down with productivity, or increased output and/or reduced cost of equipment. As AM equipment rarely goes down in price, we are primarily interested in getting the productivity up and therefore the $/hr basis down.

We once again rely on our data-driven methods. Using the TBGA control arm, we test how to get cost out of our part by examining depreciation and productivity and their contributions to making our contract manufacturing business successful.

Analyzing the Data

The TBGA control arm in this analysis is made from AlSi10Mg (AMS7018). We performed enough Modification for AM (MfAM) to make it comparable across a single laser and two different multi-laser printers. It is still what we would describe as a TBGA AM Maturity Model Level 2 part, in that it is a part-for-part replacement for the traditionally manufactured version. It exists in a fairly restrictive design space, but the MfAM we did to the design makes it more robust and improves the business case. Another way of looking at it, is that our analysis here is conservative, and for a part with more opportunity space, the business case will only get better as you can consolidate parts (Level 3, etc.).

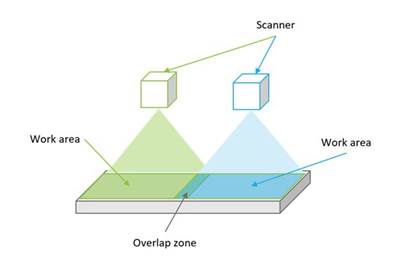

We also need to point out that our baseline printer is a familiar-looking medium-size PBF machine, with a single laser, medium bed and 400-W laser. There are a myriad of combinations that we looked at, but we are showing two additional scenarios: a large-bed, 400-W, quad laser printer and a larger bed, 1,000-W, 12-laser system.

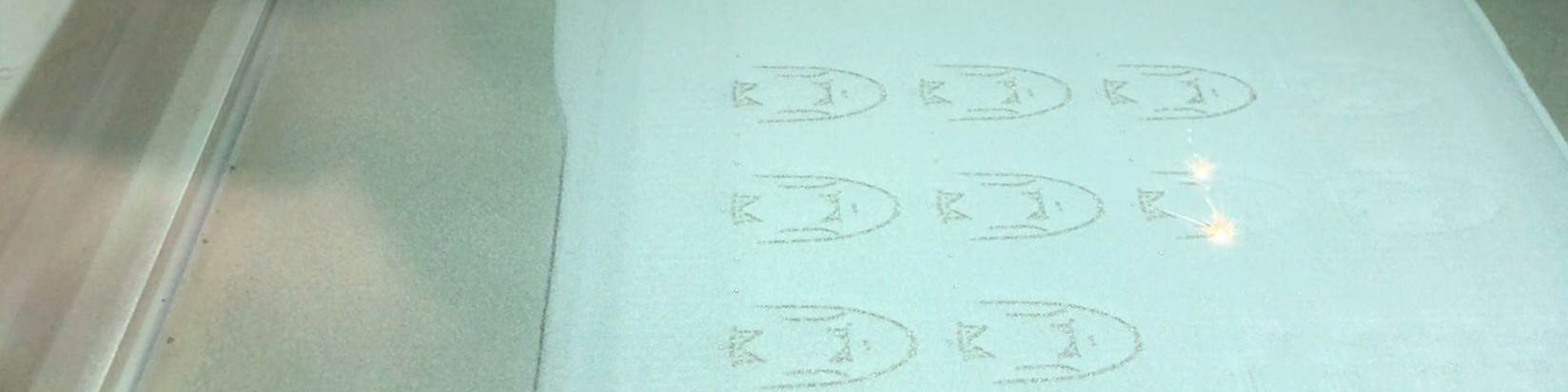

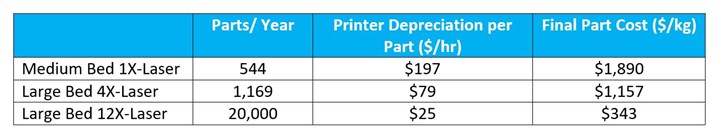

Figure 2 (below) shows the impact of productivity on the cost to produce the TBGA control arm. The dramatic reduction of the printing time is directly tied to productivity of the printer.

Productivity is a function of:

- Bed Size – Make more parts

- Laser Count – Make more parts simultaneously

- Parameters – More latitude to go to thicker layers with higher power optics

- Postprocessing – Efficiently utilize downstream batch processes

Figure 3: Part cost comparison of single and multi-laser powder bed fusion systems for the TBGA control arm.

This is a dramatic shift. Breaking this figure down further, we calculated the part throughput (i.e. parts per year), the contribution of depreciation, and the final part cost on a $/kg basis in Table 1. If we do not take our own advice from the previous articles and compare the most modern multi-laser system to our single laser favorite, if only for dramatic effect, the 12-laser system can make 36 times more parts annually! Taking our own advice and comparing that output to our trusted quad configuration, the 12-laser system can still punch out 23 times more parts.

Table 1: Part Throughput, Depreciation, and Part Cost Impacts

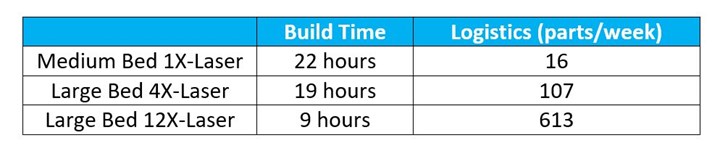

This rather significant shift in output needs to be addressed with the organization as well. The operational tempo that the multi-laser systems represent will impact how I run my shop as well as the downstream steps. I need to ensure that my equipment does not go underutilized. Table 2 shows the impact to the people side of the operations. My resource loading for break out needs to adjust, as does my logistics team. Gone are the days of starting the build on a Friday to break it out on Monday morning.

Table 2: Impact of Productivity on People Operations

The Bottom Line

Making parts is not for everyone. AM is not for everyone. Being able to match the customer requirement to the equipment on hand is critically important. Having the operational tempo to bring on a multi-laser machine is necessary, otherwise your productivity will suffer and with it go the benefits of the increased throughput.

The higher productivity of a multi-laser system will drastically alter your work week planning, and you must prepare for making significantly more parts in a five-day manufacturing week.

The good news? With the productivity attainable with the multi-laser capability, we see the cost of producing our TBGA control arm fall by 87%. This now puts it in the competitive space of casting and machining solutions in terms of $/kg. If you have the logistics to process this steady flow of parts every 9 hours, there is money to be made.

Thinking, Fast and Slow

The world of AM is moving pretty fast, creating an instinctive and emotional reaction for people to believe they must be missing out. But, as Daniel Kahneman points out in his bestselling book, “Thinking, Fast and Slow,” manufacturers must slow down and approach the question logically shifting from, “Am I missing out?” to “Is my business ready for the output?”

About the Author

John E. Barnes

John has a 25+ year career in product development and aerospace with Honeywell, Lockheed Martin Skunk Works™, Australia’s CSIRO, and Arconic (formerly Alcoa and RTI International Metals). He’s been involved in metal additive manufacturing throughout this career beginning in the late 1990s where he was part of the Sandia National Labs LENS™ CRADA. Since then, he has been in and around additive manufacturing working both technical and business cases for implementation and development efforts in materials, powders, processing and printing to mature the technology for applications.

John is recognized internationally for contributions to additive manufacturing, product development, and leadership in engineering. His groups boast world firsts in medical, therapeutic and aerospace additive manufacturing. He is a materials engineer by background but has developed expertise in manufacturing, airframe structures, gas turbines and low observables. He is currently an adjunct professor at Carnegie Mellon University and RMIT University, as well as an adjunct senior research fellow at Monash University. In 2014, he was Purdue University’s Materials Engineer of the Year, and in 2017, he was invited to join the Additive Manufacturing Technical Community as an SME AM Advisor based upon active industry contributions, reputation, and personal commitment to expand the use of additive manufacturing.

Related Content

VulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreTo Grow Additive Manufacturing Adoption, HP Is Aiming for the C-Suite

3D printing has been largely the purview of service bureaus and technical specialists but HP sees a future where it is increasingly the concern of OEM executives — and the company is taking steps to reach them.

Read MoreWhat Does AM Want? Here Are 4 Aims (Maybe 5) That Additive Manufacturing Is Driving Toward

Certain freedoms and contributing factors allow additive manufacturing to realize its full promise for production.

Read More6 Considerations When Launching an Additive Startup

Recent additive manufacturing (AM) startup owner, JP Kinerk, shares his experience by offering helpful advice for others just starting out in the additive realm.

Read MoreRead Next

Speed Is Relative in AM: A Data-Driven Comparison of Multi-Laser Powder Bed Fusion and Binder Jet Processing

There is a difference between the effective print speed and the actual cost to produce the component with AM. John Barnes compares binder jet processing with powder bed fusion for metal parts.

Read MoreAM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

Read MoreA Technical Economic Perspective on Multi-Laser Powder Bed Fusion 3D Printers

When it comes to laser-based powder bed fusion, more lasers do not always lead to greater productivity. Considerations for multi-laser 3D printing.

Read More