Lowering Barriers, Part Two: An Update on Renishaw’s Solutions Centers

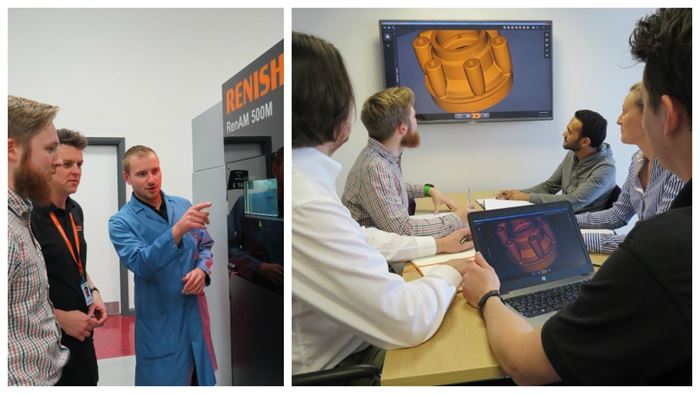

Currently in progress, Renishaw’s Solutions Center Network is intended to help manufacturers learn to use additive manufacturing effectively.

According to Renishaw, the first step to easing additive manufacturing integration is to teach users how to apply AM thinking to processing and design of parts. This belief lead the company to introduce its “Solutions Center” concept at EMO last fall, a plan that calls for the creation of 10 such centers within the next year. (Learn more about the concept here.) Each of these Centers will offer equipment and expertise to help AM users apply the technology, but a key goal is to help manufacturers learn to think with an AM mindset.

Building Progress

Marc Saunders, Renishaw’s director of global solutions centers, says the company has made great progress with the development and expansion of its Solutions Centers throughout the world since that announcement. For example, the company has completed construction on the first Solutions Center in Pune, India, which is now open for business. “We believe this to be the largest AM facility in India with three machines running today and another machine planned for early next year,” says Saunders. It is the site for a lot of development testing. Pune is also where Renishaw is developing AM software, including the new QuantAM build software that was introduced at Formnext.

Other Solutions Centers are on their way to completion as well. The Healthcare Center of Excellence in Miskin, South Wales, is now operational with dental and orthopedic implant production transferred from another site. Construction is also complete on a new building in Kitchener, near Toronto, and machines are being moved into the facility. A building has also been purchased in Richardson, Texas, near Dallas, with construction underway and a planned opening in March. Construction on both the flagship center in Stone, United Kingdom, and the German center in Pliezhausen, near Stuttgart, has also started. Lastly, a new building in Chicago is also under construction with completion anticipated by next summer.

The Vision

Each completed Renishaw Solutions Center will serve as a supported learning center for all things AM by helping potential and current users uncover AM’s possibilities, identify appropriate applications, learn best practices and examine the investment case. Every Center provides a secure development environment for prototyping, remanufacturing, part consolidation and design optimization exploration. Secure and supported access to every step of the AM process is achieved within an “incubator cell” staffed with an operator and applications engineer to consult with customers on concepts, assist with benchmarking part designs and test out processes.

Dedicated engineering and technician expertise is available within each Center, as well as non-AM equipment including five-axis CNCs for finishing and CMMs for inspection. Resources also include private offices in which to collaborate; a materials lab for QA analysis; finishing methods for support removal, polishing and surface treatment; a heat treatment room; and powder management via sieving and filter replacement. Customers begin by paying for time in the cell, but the end game in any given case is to develop a complete process to manufacture production parts.

Applying AM Thinking

But actually applying AM thinking requires more than having the right tools in place. It also requires implementing a different approach to processing and design, sharing best practices, and examining investment cases for each customer, all services that the Centers provide.

As an illustration of the design for AM (DfAM) approach used in the Solutions Centers, Saunders turns to Renishaw’s production of the world’s first 3D-printed mountain bike and the steps taken to redesign the seat post. This project entailed investigating ways to minimize weight and keep costs down. Topological optimization was used to examine material stresses and thereby determine optimal part shape and build.

Saunders explains, “The careful application of engineering processes allowed us to build a bike frame that is significantly lighter than the original, and yet still exhibits the ruggedness that is essential for extreme off-road cycling.” He emphasizes that this project demonstrates the close interaction between product and process design that is inherent to AM. The process freedom AM offers allows product designers and manufacturing engineers to collaborate to make impossible products possible.

Beyond design, the Center teams also share best practices for other aspects of AM—for example, the value of an effective process chain. “It is essential to consider the rest of the process chain that you'll need to produce your product,” says Saunders. “Information must flow up and down the chain to link processes together. Successful AM requires an effective process chain with user-friendly design tools and a range of postprocessing and metrology equipment.”

Assisting customers in making an educated AM investment is another vital service of the Solutions Center Network. This involves fully understanding a customer’s design requirements, and then proposing how these can be realized with a feasible build (orientation, supports, layer thickness, laser parameters, etc.), which results in a build time and a cost. “We may move through several design iterations that yield varying product performance levels and carry different manufacturing costs, so we gather this data for the customer to help establish the best trade-off between producability and performance,” says Saunders.

Related Content

How to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

Read MoreHow Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MoreDMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read MoreUnderstanding HP's Metal Jet: Beyond Part Geometry, Now It's About Modularity, Automation and Scale

Since introducing its metal binder jetting platform at IMTS in 2018, HP has made significant strides to commercialize the technology as a serial production solution. We got an early preview of the just-announced Metal Jet S100.

Read MoreRead Next

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More