Lattices in Footprint 3D Midsoles to Provide Custom Fit

The footwear company plans to offer shoes with custom 3D-printed midsoles using lattices for precise support and cushioning.

Custom footwear is a fast-growing market for 3D printing, which unlike injection molding is viable for serving “the market of one.” Footprint 3D, a footwear manufacturer that grew out of a thesis project, plans to take custom footwear one step farther: offering shoes with midsoles that are not only shaped to a person’s foot, but can be tailored to provide support exactly where it is needed through the use of lattice structures made possible by 3D printing.

Footprint 3D founders Tim Ganter and Matthew Flail met as students at Philadelphia University and collaborated on a thesis project in their final year of graduate school. Inspired by their own difficulties in finding comfortable shoes, through research the two discovered that improperly fitting shoes is a widespread problem. "Tim and I found that standard sizing and wearing improperly fitting shoes is really a global problem," Flail stated in a recent webinar presentation, noting that proper fit is important for the average customer as well as those with rheumatoid arthritis or other medical issues.

Ganter and Flail started Footprint 3D to offer a lifestyle shoe that would be an alternative to expensive and often unfashionable custom shoes and orthotics. The shoe they’ve designed is lightweight, offers support through a midsole designed to match the contours of an individual’s foot, and features knit uppers inspired by fashion trends. The company plans to launch its first shoe in 2018, and will serve both patients who have a medical need for custom shoes and consumers who simply want a better fit.

The ordering process starts with capturing the shape of the customer’s foot. The company is currently experimenting with options, but the cheapest and most effective method used in beta testing has been foam impression boxes. (Other options like in-store scanners or even a smartphone app could come later.) Beta testers mold their feet into the foam and mail it back to Footprint 3D; the company can then take a 3D scan of the impressions and generate CAD models of the midsoles using Autodesk Fusion 360.

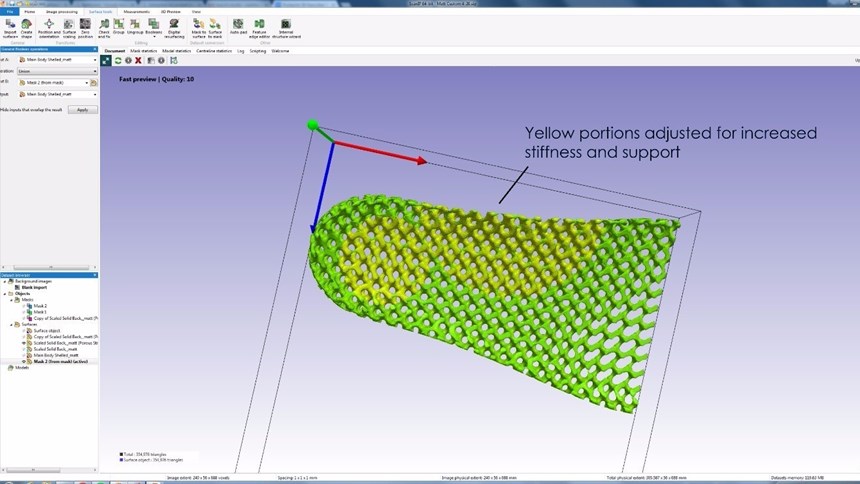

CAD models are imported into Synopsys’s Simpleware software as STL files. From there, a CAD module within Simpleware enables incorporating lattice structures within the solid model, providing cushioning while reducing the weight of the midsole. While early designs (such as the shoe pictured above) left the lattices exposed, these shoes proved more prone to breakage; new designs enclose the structures for cleanliness and better durability. After printing, the midsole is assembled into a shoe with a knit upper also designed by Footprint 3D and rapidly delivered to the customer.

The manufacturing process "allows us to create an infinitely variable range of sizes without ever opening a mold," Flail says, reducing the time associated with injection molding, as well as the waste created through the machining of tooling. For the conventional consumer, this process will result in a shoe customized for the length, width and curvature of each individual foot.

But, the incorporation of lattice structures will allow Footprint 3D to go further, building in varying levels of support and flex where needed. Through the tools available in Simpleware, it is possible to change the volume and node thickness of the lattice in specific regions of the midsole. This capability could allow for intricate flex patterns and support zones for corrective shoes that wouldn’t be possible in traditionally molded soles.

This particular alteration service will be targeted primarily to medical clients and customers, Footprint 3D says, as it relies on obtaining pressure map data of the customer’s foot. For now, the equipment necessary for gathering that data is limited to podiatrist offices and select specialty running stores. Footprint 3D is currently working to build a network of podiatrists and foot health professionals to offer this option for corrective footwear more widely.

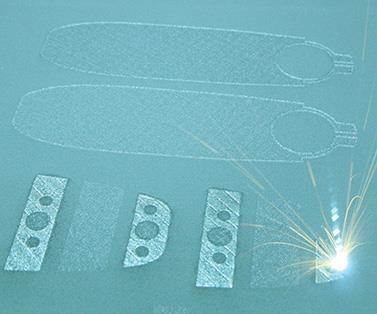

The soles will initially be 3D-printed via FDM or selective laser sintering (SLS) using flexible TPUs; other elastomeric materials could come later. Early tests indicate that the particle bonding of the TPU material coupled with lattice structures allows the energy from each step to be dispersed evenly and at a slower rate. According to Footprint 3D, this results in added stability and reduced impact on the wearer over time.

Related Content

Possibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

Read MoreLarge-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

Read MoreHow to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

Read MoreActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

Read MoreRead Next

Lattice Generation Software Advances Bike Component Design

Smart Aero Technology's bike stem design needed to be optimized for additive manufacturing. The ScanIP software from Simpleware reduced the stem's weight, increasing its strength.

Read More3D-Printed Sneakers Gaining Traction

Under Armour, Adidas, Nike and New Balance are applying different additive manufacturing technologies and materials for customized kicks.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More

.jpg;width=70;height=70;mode=crop)