Lattice Generation Software Advances Bike Component Design

A U.K. research project redesigned a bike stem with an internal lattice to reduce the amount of material needed while maintaining strength.

Share

Additive manufacturing can place material exactly where it is needed, enabling the creation of parts that are lighter but just as strong as their conventionally machined counterparts. But in order to strike the right balance between weight and strength, design changes are necessary. Research conducted under the umbrella of the U.K.-based SAVING Project explored ways of reducing material usage via additive manufacturing. One project to redesign a bike stem relied on an internal lattice structure to reduce the amount of material needed to create a strong, functional bike component.

The SAVING Project (which stands for Sustainable product development via design optimization and AdditiVe manufacturING) consortium was established in September 2009 and was funded by the U.K.’s Technology Strategy Board (now known as Innovate UK). Partners included the University of Exeter; rapid prototyping firm Plunkett Associates; additive manufacturers 3T RPD and RaceWare Components (an AM venture started by a 3T RPD employee); software developers Delcam and Simpleware; and AM equipment manufacturer EOS. With the tagline “Making more with less,” the project’s goal was to improve sustainability and reduce energy consumption, both in production and end-use products, through strategies like lightweighting and material reduction.

Smart Aero Technology, a research and design group that specializes in cycling aerodynamics, approached the SAVING Project in 2012 about developing a bike stem that would be easier to produce in various sizes and superior in performance to those on the market. The stem connects the handlebars to the steerer tube, and its strength and stiffness affects the bike’s handling. A stiffer stem means better power transfer and momentum. Weight and aerodynamics are also important considerations; the lighter and more aerodynamic the stem, the faster the bike can be.

The project collaborators worked from an existing bike stem designed and produced by Smart Aero in carbon fiber. A challenge with this stem is that many tools are required to produce the range of lengths and angles offered, making production costly. In building the stem additively, the SAVING Project hoped to reduce the cost of manufacturing the bike stem and improve its aerodynamic performance while maintaining strength.

Consortium member 3T RPD took the lead on the project. After several brainstorming sessions, the company determined that the project’s goals for the bike stem could be achieved with a two-part design strategy:

- A reduced external wall thickness that would reduce weight and optimize air flow, and

- An internal lattice structure that would further reduce weight while providing strength and support for the stem’s outer skin during building.

3T RPD turned to project partner Simpleware for the creation of the internal lattice. Simpleware is the developer of ScanIP, a software program for processing 3D image data that is capable of generating STL files for 3D printing. When equipped with the Simpleware +CAD module, the program can generate lattice patterns to fill volumes of a model destined for additive manufacturing. This capability helps to speed up the design process and is used for lightweighting applications in aerospace and automotive industries. An added benefit is that the resulting part design is highly scalable, so that future parts of similar shape could be built at little extra development cost.

The lattices created via Simpleware’s software consist of repeating cellular units available in various designs. Though the unit designs are generic (custom designs can also be loaded to the software), the freedom to adjust the size of the cell and the volume fraction of the fill permits a range of variation. The software automates the creation of the lattices, but does not select these variables; instead, the designer selects the pattern, cell size and volume fraction combination.

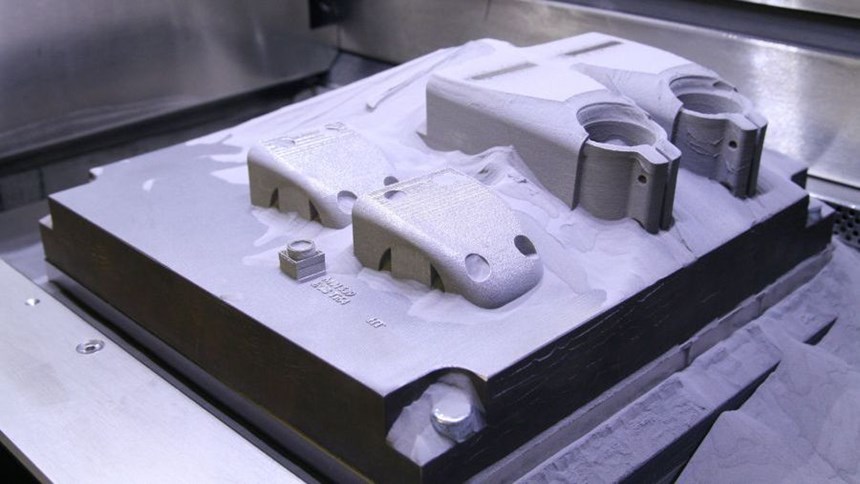

For the bike stem project, 3T RPD and Simpleware worked from CAD data for the existing Smart Aero bike stem. Finite element analysis (FEA) was conducted in SolidWorks to help determine the best shape, size and density of the internal lattice based on the bike stem’s external envelope, physical loads and constraints. Titanium was chosen as the build material because of its high strength-to-weight ratio.

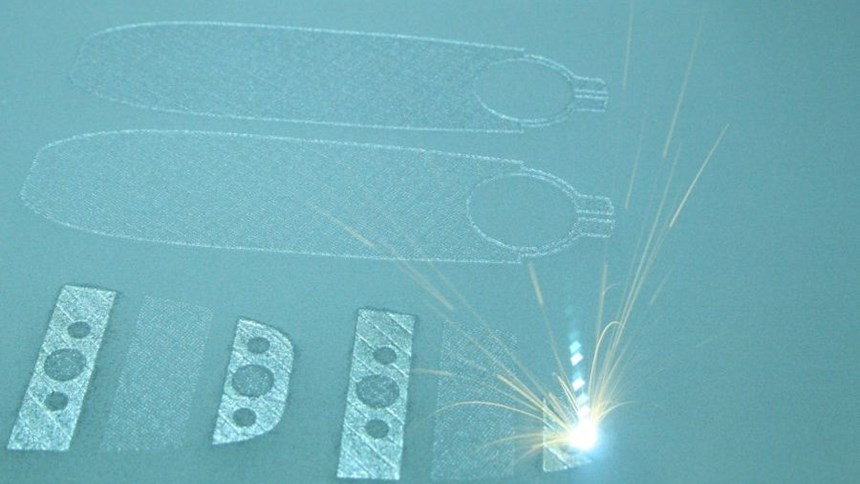

Nylon prototypes of the bike stem were built at 3T RPD on an EOS P machine, a selective laser sintering (SLS) system. Finally, test parts were built in titanium using an EOS M direct metal laser sintering (DMLS) machine. Following the build, supports were removed from the metal bike stem using a wire EDM, and a micromachining process was used to polish the part to a mirror-like surface finish.

The DMLS bike stem was then tested to determine its usability. While the stem performed well, it was ultimately found to be too stiff for most riders’ needs because of the small cell size and high volume fill. While stiffness is a desirable quality in a bike component, too much makes for bumpy ride. Some flex is necessary for the comfort of the rider. Additionally, the stem remained expensive to manufacture—according to 3T RPD, the component would have cost around 3,000 pounds (nearly $4,500) on the market. Approximately one-third of this cost would have gone toward the micromachining process (MMP) polishing to smooth the surface of the rough DMLS part.

While the project did not directly result in a bike stem available for sale, technologies and strategies used in the SAVING Project are being applied to new bike components produced by the team of 3T RPD, RaceWare Components and Smart Aero Technology. By adjusting parameters on the SAVINGS Project bike stem and opting for a more traditional finish, Raceware has been able to additively manufacture bike stems that currently retail for less than 1,000 pounds.

Related Content

Aircraft Engine MRO: How Additive Manufacturing Plus Robotic Finishing Will Expand Capacity for Blade Repair

AM offers the chance to bring fast, automated processing to individualized, part-by-part restoration of turbomachinery. A cell developed by Acme Manufacturing and Optomec is able to automatically repair 85,000 unique aircraft engine blades per year.

Read MoreSpherene Creates Metamaterial with Geometry Derived from Spheres

An algorithm developed by Spherene Inc. generates Adaptive Density Minimal Surfaces (ADMS) as a self-supporting infill strategy that can be used to reduce mass and manage material properties in 3D printed parts.

Read MoreAdditive Manufacturing Production at Scale Reveals the Technology's Next Challenges: AM Radio #28

Seemingly small issues in 3D printing are becoming larger problems that need solutions as manufacturers advance into ongoing production and higher quantities with AM. Stephanie Hendrixson and Peter Zelinski discuss 6 of these challenges on AM Radio.

Read MoreTaking the Leap into Additive Manufacturing

SolidCAM’s partnership with Desktop Metal, and its in-depth experience in combined metal 3D printing and CNC finishing, is aimed at making additive manufacturing accessible and profitable for job shops and other manufacturers.

Read MoreRead Next

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More

.jpg;width=70;height=70;mode=crop)