Laser Cutting Specialist Develops Large-Travel Additive Approach

For SLM of parts that are multiple feet long, this machine’s build chamber travels throughout the machine area to 3D print the solid part one section at a time.

Of the various limiting factors affecting powder-bed additive manufacturing processes such as selective laser melting (SLM), this one is perhaps the most limiting of all: the build size. Big metal parts can be made additively through metal deposition—a coarse process—but the powder-bed metal AM machines that are capable of fine detail often have build envelopes less than one foot square. Large-travel machines might extend this up to about 16 inches square. Any part much longer than this seemingly is not a candidate for being 3D printed in one piece through a powder-bed process.

And yet, the part seen in the photo above was indeed built in one piece through SLM. This 316L stainless steel part is 900 mm long, or just under 3 feet.

The part was made on an SLM machine developed by machine tool builder Adira, based in Vila Nova de Gaia, Portugal. The innovation that makes big parts practical on this machine is a mobile chamber moving across the powder bed so that the large piece can be built in sections. One other interesting detail about the machine that made this part is that it combines both powder-bed and metal-deposition AM into the same platform.

“Three years ago, we saw we needed to get into AM,” says Filipe Coutinho, company product development engineer. More specifically, the company knew it wanted to provide AM for large metal parts—an industrial demand obvious to this company that seemed underserved. As a maker of laser machines for sheet-metal cutting, the company already had expertise with lasers, and was already oriented toward using those lasers across large-travel machines. It set about developing both metal-deposition and powder-bed machines, both of which it is now bringing to market.

With the metal deposition system it developed, the company recognized that a typical use is likely to be building additive features onto existing large workpieces. Adira therefore focused on allowing an easy transition between laser cutting and laser deposition of material. The system the company developed requires a manual change between these operations, but the change is “very fast,” Coutinho says. “You affix the cladding nozzle and center it—that’s it.” The company’s additive machine offering this system therefore could spend much of its time running as a straightforward metalcutting machine until the additive capability is needed.

By contrast, the large-travel SLM system developed by Adira is much more novel relative to other additive machines. One of the challenges of getting to large travels with a powder-bed machine is controlling the environment across such a large volume. Adira accomplished this with a smaller-volume chamber—just under one foot square—that travels the entire machine area and descends onto the powder from above to contain one section of material at a time. Building the sample part shown took about 80 hours, and the chamber was repeatedly in motion all throughout this time. The following video shows the machine movement, with the chamber advancing from section to section with each single build layer of the part:

Adira recently introduced its new additive offerings using a single machine at the Euroblech trade show in Germany, a machine employing both of these additive capabilities. Marrying metal deposition with SLM in one machine was as much a matter of marketing as engineering, Coutinho says; putting both capabilities in one machine created an impressive showcase for the additive introduction. In general, though, users will want either one capability or the other—either deposition or SLM.

Except: Some users might want both, he says. Manufacturing research facilities are an example. With the demonstration machine, Adira has shown it can combine the capabilities, and in testing it has even succeeded in using them together. Laser deposition can add features onto an SLM part (though the reverse is not possible).

Development still continues, he says. There is much yet to do—significant opportunity exists for further advances, particularly on the powder-bed machine. “We're looking at ways to bring more power to the process, to obtain larger controlled spot sizes for higher build rates,” Coutinho says. For large-size parts on a powder-bed machine, enabling the large build is just the start. “For the next stage, to do large parts more cost-effectively, we are going to need more speed.”

Related Content

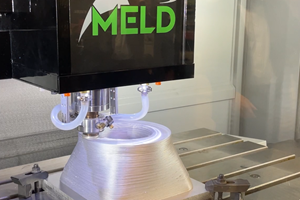

3D Printing From Barstock Using Friction Stir Welding (Video)

A look at the Meld Manufacturing metal AM process. The machine tool in this video builds an additively manufactured part by rotating and compressing metal bar.

Read MoreAircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

Read More“Mantis” AM System for Spacecraft Uses Induction for Deposition

The metal 3D printing system melts wire without lasers. 30-foot-diameter parts are built on a rotary-feed system that eliminates the need for a large machine frame or gantry.

Read MoreLarge-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

Read MoreRead Next

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More