The key to scale production with metal powder bed fusion (PBF) likely isn’t print bed size or number of lasers, but something more basic: process control.

At least, this is the approach that Velo3D is taking with the recent announcement of its Sapphire XC, for “eXtra Capacity.” This new metal 3D printing system adds considerable build volume over the current Sapphire model, with a 600-mm diameter and 550-mm build height. The XC will also be equipped with eight lasers to the Sapphire system’s two. In addition to allowing for larger parts, these features make the XC more productive and help drop the price per part produced.

But Velo3D is not displacing the existing Sapphire metal 3D printer. In a webinar held Thursday, October 22, Velo3D founder and CEO Benny Buller called the Sapphire XC a parallel system, saying, “We see these two products continuing to operate in tandem.”

Velo3D anticipates that customers will continue to buy and use the original Sapphire 3D printers for development of new products and initial low-volume production, but then ramp up to full-scale quantities with the XC. The larger machine will allow users to take advantage of productivity gains (as much as five times the throughput of the existing Sapphire system) and cost-per-part savings as high as 75%.

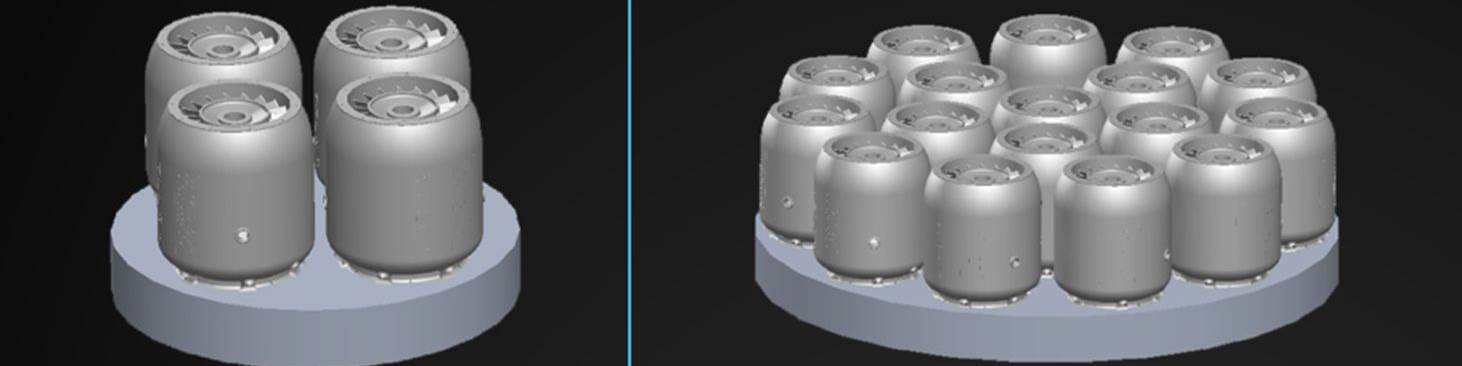

While the XC’s expanded build volume also makes it suitable for building larger parts, Velo3D mostly anticipates that users will apply it for printing more production parts more quickly. The existing Sapphire system can today print 4 of the microturbine engines or 19 of the impellers pictured in one batch, but the XC will accommodate 17 engines and 66 impellers at once. Image Credit: Velo3D

Using the machines in tandem this way will be possible, Buller says, because the part “recipes” — the parameters that control laser power, gas flow and other critical conditions — are directly transferrable between the smaller and larger Velo3D machines. Both systems use the same architecture including the software, sensors and calibration features that enable “SupportFree” metal 3D printing, but the ability to print complex geometries without supports is actually more of a side effect rather than the point. The same process control measures that make free-floating parts possible will also ensure consistency as part files move from model to model, or simply machine to machine.

The Sapphire XC is currently available for preorder. Velo3D expects to expand its physical presence in the Campbell, California, area to produce the machines, with delivery planned for Q4 of 2021.

Related Content

-

Additive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

-

3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

-

New Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

.jpg;width=70;height=70;mode=crop)