Share

According to Professor Timothy W. Simpson, co-director of the Center for Innovative Materials Processing through Direct Digital Deposition (CIMP-3D) and professor at Penn State University (PSU), there are two reasons that the time is right for a master’s program in additive manufacturing (AM). The first is the technology’s growing maturity and complexity, spanning manufacturing, mechanical and materials engineering along with design, postprocessing and other disciplines. As Prof. Simpson puts it, “When you look at the breadth of knowledge that you need now for additive, there is more than enough content there to create a degree.”

But secondly, a postgraduate program in additive manufacturing makes sense at this juncture because of demand. Manufacturers are seeing the promise of AM, and many are eager to implement it, but to do so requires expertise and skill that is in short supply. The specialized knowledge that additive represents makes such a degree program not only viable but desirable.

Organic Growth

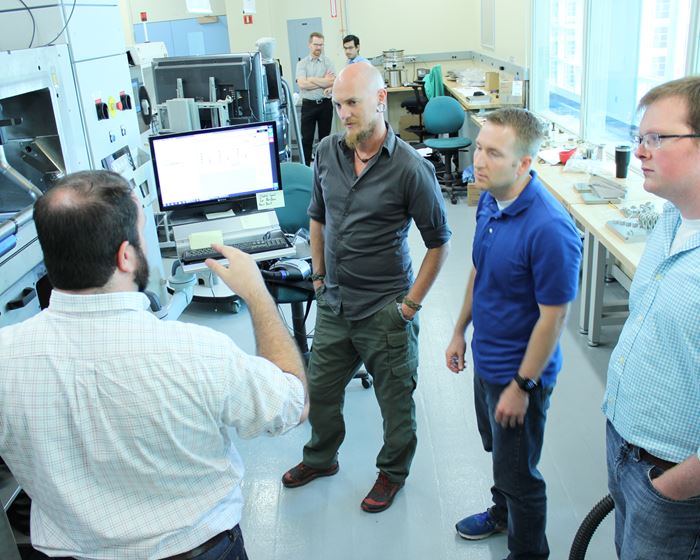

Awareness of both AM’s complexity and the demand for higher education surrounding it helped drive the creation of the engineering master’s degree in additive manufacturing and design now offered at Penn State. The program, which today spans two colleges and five departments, dives deep into many facets of additive manufacturing and offers two different enrollment options to support both traditional, on-campus students as well as those already in the workforce who want to expand their knowledge into additive.

Whereas many colleges and universities now offer one or maybe several courses in additive manufacturing, PSU’s degree program covers everything from powder characterization to design for additive manufacturing (DFAM) to postprocessing and inspection. While the course diversity is today an acknowledged strength of the program, it grew from something more organic. “As interest in additive was growing we were starting to add more new courses that had an additive flavor to them,” Prof. Simpson says. “We found we were creating and co-teaching classes in various disciplines—design, materials, AM processes. For a while we thought, ‘Wouldn’t it be nice if they were all in one department?’ but then realized no, that’s our strength to have depth in each of the key areas of additive.”

Masters students in the program move between disciplines to complete their coursework, reflecting the varied areas of expertise within additive manufacturing. There are five core classes within the degree. They cover AM processes, AM materials, design for AM, the science of AM and hands-on lab work. Students also complete two electives, which might focus on a more specific topic such as CT scanning, postprocessing or even bioprinting. There’s also a final project and paper—this document doesn’t need to be published, however, which means that students can focus on a topic or specific part relevant to their employer, even if the work is proprietary.

This accommodation is just one way that PSU is helping to meet the growing demand for AM training within the existing workforce, as well as train the next generation of engineers, designers and manufacturers. The master’s degree program encompasses two tracks, one a traditional, on-campus experience and the other consisting of online coursework with a one-week intensive lab experience on campus. Why the online option? “Many of our students are already part of the workforce,” Prof. Simpson says. “They can’t commit to two years on campus. We wanted to make it readily available online so you can complete the degree while you’re doing your day job.”

Students in the program come from a range of backgrounds, including younger professionals just a few years out of school, more senior engineers looking to advance their skills, employees who work for AM machine and auxiliary equipment suppliers, and even teachers at other institutions who find themselves asked to teach AM courses or expand their curriculum. Also represented are Ph.D. candidates, certificate students and graduate students participating in AM classes to augment studies in their traditional degree program. As of fall 2018, the program had 57 online students from 28 different companies and 10 resident students.

It’s important to note that a master’s degree in AM is not meant to be an endorsement of students’ skill exactly, but of their awareness. The goal for students is that when they leave, they are conscious of the salient benefits, issues and problems associated with AM and DFAM, and more effective and efficient at executing the pieces of the process. The degree is a foundation on which to continue to build, not an end in and of itself.

That’s far different than the machine- or application-specific training mentality that often emerges within an industrial setting, but PSU believes this philosophy meshes with the changing nature of additive at large and should continue to serve students long after they’ve completed the degree.

“We want to make sure that they understand the key questions to ask and the new tradeoffs that have to be made with AM,” Prof. Simpson says. “We are not trying to train them to use a specific machine or AM process.”

The Emerging Structure

Although the courses in the curriculum first began to emerge organically, arranging them into a more formal program of study involved answering some definitive questions. Prof. Simpson says the fundamental, foundational questions the university had to face included the following:

What do we teach? Because additive encompasses so many varied topics and disciplines, it’s important that the curriculum not function within a silo. At Penn State, many of the courses that make up the degree emerged in disparate departments and even different colleges, but bringing them together as program requirements was a deliberate decision—as was the program’s emphasis on design. “We were very intentional about the ‘design’ portion of the degree,” Prof. Simpson says. “It’s not just about the machines and the fabrication of the 3D-printed parts. Design is a critical component across all five core courses and is essential for achieving one’s value proposition with AM.”

The faculty also recognizes that the curriculum will grow and expand as AM matures. A future addition to the program might be a course in AM economics, for example, that could be co-taught with a professor from the college of business and cover cost models for additive and the impact on the broader supply chain. Prof. Simpson anticipates that new classes will emerge based on student interest as well as market demand.

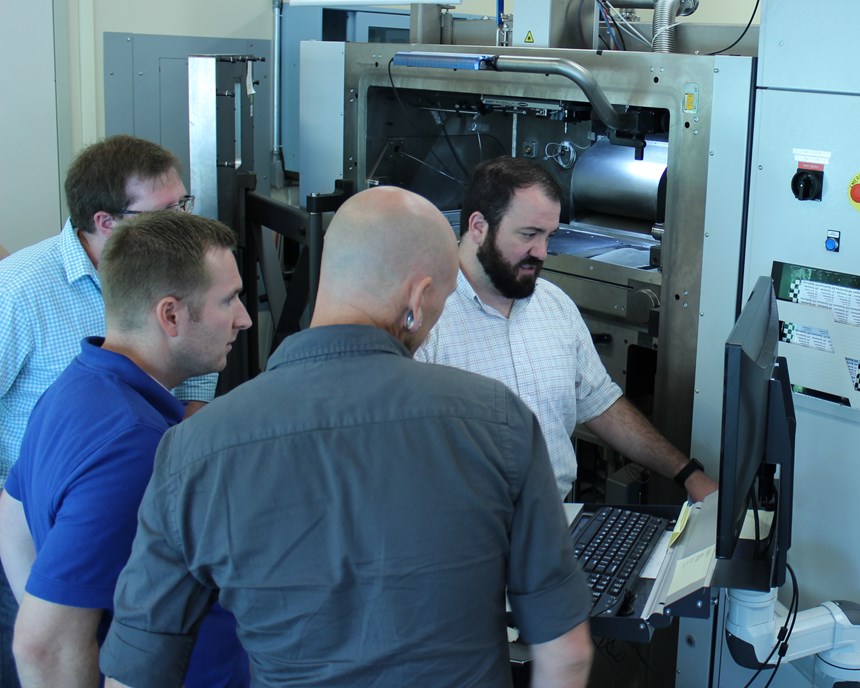

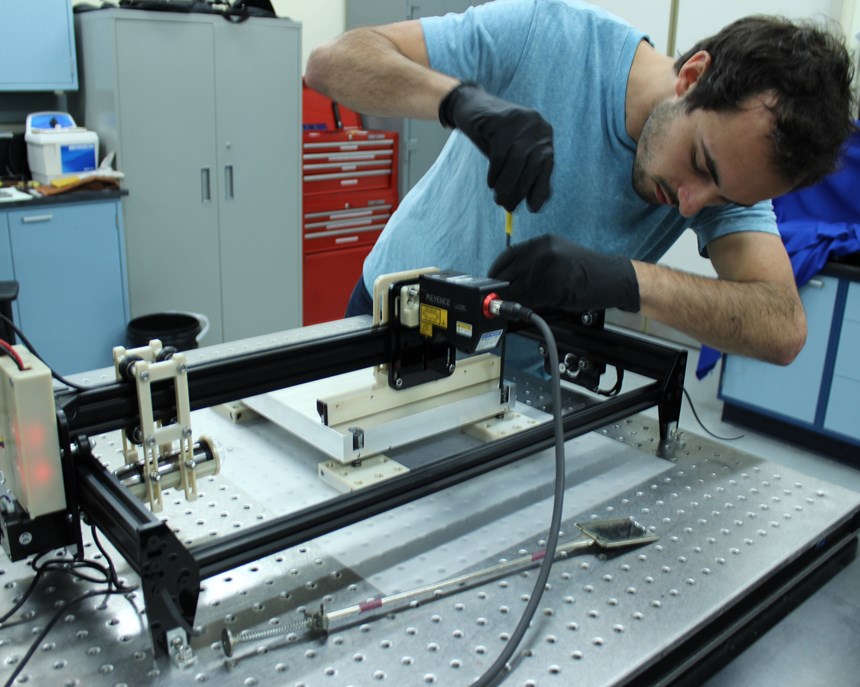

How do we teach it? Both the on-campus and online variations of the degree program include classroom work as well as in-person, hands-on lab work. For the on-campus students, this manifests as a semester-long lab section totaling about 45 hours during which they redesign, prototype, print, postprocess and inspect a given part such as a piston crown. For online students, who spend only a week in labs at PSU to meet this hands-on requirement, the assignment is more standardized, with all students manufacturing the same part without design changes to ensure that they can complete the project within a 40-hour week.

While more lab time might be beneficial, “the goal is not to train technicians,” Prof. Simpson says. The hands-on experience is more about illustrating classroom lessons than developing expertise in operating a specific machine. Evaluation is based on a student’s ability to execute the workflow, rather than an expected build outcome.

What tools do we use? One of the most significant challenges in additive manufacturing is the sheer volume of choices—in process, in hardware and in software. Faculty members need to be careful in their selections of tools for coursework, again because the goal is to teach underlying principles for AM rather than a skill set applicable only to one specific tool. One challenge for the first class of master’s students was an overabundance of software options for designing and planning AM builds, Prof. Simpson says. With too many choices and limited time to learn, students became overwhelmed. “We quickly realized we had to choose both software and hardware based on what can we teach and demo in a short amount of time, and what will give our students a good hands-on experience,” he says.

Who do we teach? The online track for Penn State’s AM master’s program is unconventional for an engineering program, but it allows the university to serve a broader student base including established manufacturing professionals who can continue to work while they complete their degrees. This isn’t just a way of attracting more enrollment; bringing professionals into the program benefits the program’s residential students as well as the faculty. Students benefit from the networking opportunities the arrangement affords, while faculty get better insight into the AM problems that companies are facing and can better direct their research.

Prof. Simpson also sees the potential for the program to function as a talent pipeline of sorts. He is currently working with companies involved in the online program to provide summer internships and projects for the residential students. This arrangement gives resident students real-world experience while in the program and provides companies with direct access to new AM talent.

Program’s First Graduate

In September 2018, the program graduated its first student, Rakshith Badarinath. “When I started at Penn State in 2015, there was no formal additive manufacturing program here,” he says. “In my first semester of classes, I remember taking an additive manufacturing process course that just got me hooked. Some of the professors started offering different courses, and I started taking them all.”

Badarinath is on track to complete a Ph.D. in industrial engineering with research in process control for polymer 3D printing. When PSU introduced the AM master’s program in 2017, he saw it as a good fit for his current course of study and chose to enroll, having already completed some of the required coursework. Now as a graduate, he has an appreciation for the breadth of the program.

“Taking all these courses in many different departments gives you a perspective from all sides of the additive manufacturing process,” Badarinath says. “If you take the example of a powder-bed fusion process, an industrial engineer like me would be more interested in the process side of it—maybe process monitoring or controls—but a materials scientist would be more interested in the material properties and the physics behind the process. Learning everything from different perspectives gives you an edge in better understanding the process, and in better troubleshooting problems.”

And as more and more manufacturers adopt additive manufacturing, this is an edge they will increasingly need.

Related Content

3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read More10 Important Developments in Additive Manufacturing Seen at Formnext 2022 (Includes Video)

The leading trade show dedicated to the advance of industrial 3D printing returned to the scale and energy not seen since before the pandemic. More ceramics, fewer supports structures and finding opportunities in wavelengths — these are just some of the AM advances notable at the show this year.

Read MoreHow Siemens Energy Applies Additive Manufacturing for Power Generation and More

At an applications center in Orlando, Florida, a small team of AM specialists is spanning industries by 3D printing parts to support both Siemens Energy power generation systems and external customers.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreRead Next

Video: Inside the Penn State Additive Manufacturing Master's Program, Part 4

Kevin White, mechanical engineer at the Naval Nuclear Lab and student at Penn State, shares how a higher education in AM provides benefits beyond technical training.

Read MoreVideo: Inside the Penn State Additive Manufacturing Master's Program, Part 2

A conversation with Brad Hanks, Ph.D. student at Penn State University, illustrates the intersection of optimization and AM with the example of an electrode for cancer treatment surgery.

Read MoreVideo: Inside the Penn State Additive Manufacturing Master's Program, Part 3

Alan Suarez Garcia, advanced manufacturing engineer at GE Healthcare and master's student at Penn State, explains how this degree program changes how he looks at manufacturing.

Read More

.jpg;width=70;height=70;mode=crop)