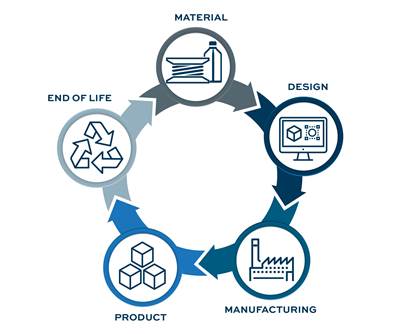

Additive manufacturing can be applied in every stage of the circular economy. View on Slideshare or download a printable PDF of this infographic. Header image at the top of this post courtesy 3Devo.

The circular economy — an economic model predicated on keeping materials in play for as long as possible — needs additive manufacturing. No other manufacturing method offers the design freedoms that 3D printing does. No other method can produce in as small a footprint, spread around the globe, sending products through numerous small supply chains. And perhaps no other method is so capable of turning production on its head, and forcing manufacturers, designers, inventors and even consumers to think differently about what gets made, bought and used.

On the flip side, additive manufacturing may not need the circular economy exactly — but it will certainly benefit from widespread enthusiasm and efforts toward sustainability and circularity. Those who wish to produce more efficiently, or consume more responsibly, will likely be drawn to 3D printing as the manufacturing method that can more easily make what is needed, and only what is needed on demand. As supply chains begin to rebuild in the wake of the coronavirus pandemic, those looking for better solutions will be naturally drawn toward principles of both additive manufacturing and the circular economy.

There are numerous benefits to be gained from pursuing both of these ambitions, which we’ve visualized in the infographic at the top of this post. Flip through the Slideshare version above or read on to learn how 3D printing and the circular economy interact in each of the five nodes. (You can also download a PDF of the complete infographic.)

1. New Material Options

AM offers the ability to manufacture with new and different materials like innovative composites, and to apply tricky materials in new ways. But moving to 3D printing for production often means there isn’t a one-to-one alloy or polymer substitute for a conventional material, which also means that this is the perfect time to consider a more renewable feedstock such as metal powder made from recyclables or polymers made from plant sources rather than petroleum. As an added bonus, the design possibilities opened by 3D printing can help one material do more, reducing the total part count which can ultimately simplify material recapture.

2. Design Freedoms

3D printing makes it possible to realize the organic, asymmetric and complex geometries created by topology optimization and generative design software. Yet its power is not just in building new shapes, but in creating parts and components that are designed to serve a specific function free from many of the limits of conventional manufacturing. Without molds or other incumbent tooling, manufacturers are more free to make exactly the right size and configuration of the part that is needed. Parts can contain less material, which reduces or eliminates in-process waste, and designing them this way reduces the amount of time they spend in processing — the inverse of subtractive machining, where every bit of material removed adds time and cost to the project. 3D printed designs can also consolidate assemblies, which ultimately saves time and labor in production and again, simplifies material recapture.

3. Sustainable Manufacturing

The digital nature of 3D printing often makes it a more sustainable and efficient method of manufacturing. Making a 3D printed part requires only the printer, material and file, avoiding the incumbent costs of conventional manufacturing such as mold tooling, jigs and fixtures, oversized stock material, and more. As a result, production becomes more efficient and can take place as needed. On-demand manufacturing allows for reduced stock held in inventory. 3D printing can also potentially occupy a smaller footprint than a conventional injection molding or machining operation; this fact along with the easy mobility of digital files makes distributed manufacturing possible. Parts can be 3D printed as they are needed, close to where they will be used, reducing each piece’s carbon footprint and getting it to the user faster.

4. Better Products

The aforementioned advantages of design freedom and sustainable, on-demand manufacturing enable 3D printing to create better products. Without a reliance on hard tooling, 3D printing makes it possible to easily customize individual parts. Shoes, jewelry, furniture and more can be made to suit the customer’s body, budget and taste. Being able to produce on-demand allows these products to be made to order, avoiding the need to produce, store and potentially discard inventory. Bespoke products that fit well or serve a specific niche for the customer can also be longer-lasting than their conventionally produced counterparts, reducing consumer waste. Furthermore, 3D printing makes it possible to incorporate sensors, monitoring devices, RFID tags and QR codes that can be used to identify and monitor an object over the course of its life; a smart product like this could alert the owner when it needs repair or has reached the end of its usable life, and could indicate to a recycling facility its precise material makeup, for instance.

5. Simplified Resource Recapture

Additive manufacturing’s preceding benefits can all potentially contribute to simplified material recapture and reuse. Fewer materials and consolidated assemblies limit the number of fasteners and individual materials that must be separated in order to recycle, remanufacture or compost an item. New design possibilities via 3D printing can make reuse simpler, perhaps by building in exchangeable parts or reducing the complexity of a component. Manufacturing sustainably via 3D printing means levels of production can more closely match demand, reducing waste, while better products in circulation may limit how much composting/recycling is truly necessary. Finally, 3D printing also represents a use case for recycled materials from other industries; used water bottles, trimmings and chips from other processes, scrap metal, and more can all be transformed into 3D printing feedstock.

Click here to download a printable PDF of the complete infographic.

Related Content

Concept Sneaker Boasts One-Piece 3D Printed TPU Construction

The Reebok x Botter Concept Sneaker Engineered by HP premiered at Paris Fashion Week, hinting at manufacturing possibilities for the future of footwear.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreHow Large-Format 3D Printing Supports Micro-Scale Hydropower

There is potential hydroelectric power that has never been unlocked because of the difficulty in capturing it. At Cadens, additive manufacturing is the key to customizing micro-scale water turbine systems to generate electricity from smaller dams and waterways.

Read MoreNext-Gen Horse Trailers to Be Built With Robotic 3D Printing

Double D Trailers is currently developing a prototype horse trailer that will be made with large-format additive manufacturing. The technology brings potential benefits for labor, weight and design features to this subset of recreational vehicles.

Read MoreRead Next

Additive Manufacturing Will Aid And Accelerate The Circular Economy

A circular economy links material, design, manufacturing, product and end-of-life in a continuous, sustainable loop. This special report illustrates the roles for 3D printing every step of the way.

Read MoreSustainability’s Moment Is Additive Manufacturing’s Moment

The disruption needed by additive manufacturing closely mirrors that required to implement the circular economy. Both can be pursued simultaneously — and the right time is now.

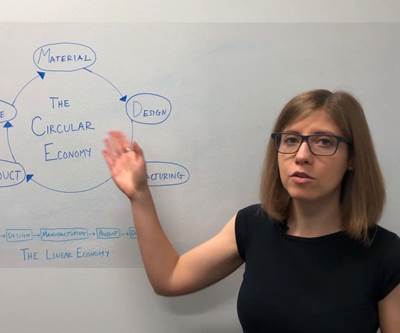

Read MoreWhat Is the Circular Economy, and How Can 3D Printing Help? (Video)

What does it mean to be sustainable, to manufacture in a circular economy? And where does 3D printing fit? These questions and more answered in this video, the first of our 3D Printing and the Circular Economy series.

Read More

.jpg;width=70;height=70;mode=crop)