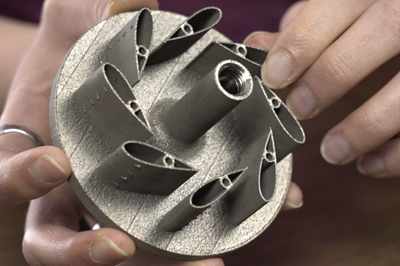

At Oak Ridge National Laboratory, additive manufacturing machines supplied by GE Additive were used to make hundreds of turbine blades used in testing of 3D printed blades conducted by Solar Turbines.

At Wagner Machine Co. in Champaign, Illinois, an AM machine from Velo3D produced a turbine housing instrumental to a new compact generator being created by KW Micro Power.

At Penn State, gas turbine researchers are working with the university’s AM department to apply machines from 3D Systems and Xact Metal to evaluate the design changes 3D printing can bring to turbine swirlers.

These three components (find our articles here covering turbine blades, a turbine housing and 3D printed swirlers) do not fit together and have little to do with one another. They relate to three different conceptions of a turbine. The researchers involved quite possibly have not met one another — and yet this last fact alone says something important about the impact AM will have. We can see how additive enables design changes on the level of one part or component, and this is in itself is significant. But the day is coming when we will discover AM has changed entire systems, transformed and improved what these systems can do, in part through the way it changes many different components working together.

We have devoted coverage recently to noticing this; to seeing the different advances that will ultimately find one another and weave together. Our theme in various articles we have posted recently (including those linked above) is power generation. It is hard to imagine a system that is more fundamental. And as recent articles reveal, various crucial components in power generation, and various types of power generation — not just gas power but also nuclear power and hydropower — are being reevaluated in light of the changes AM can bring.

The arc of this will be long. As multiple applications illustrate, the first step for AM will be just to demonstrate it can do the work. However, the arc will also be inevitable. Power generation, as a sector, will not deny itself the improvements additive can bring. AM’s efficiency improvements come from the chances to run hotter, capture losses and improve combustion — the aims of the three applications described in the first three paragraphs above. The value of these benefits is too great not to embrace them.

Why then does the advance toward these benefits seem slow-moving? Why does technology adoption take a long time? Various reasons. New possibilities arising from new technology not only have to prove themselves, but also have to await the moment when fundamental changeover is possible. Plus the path to full maturation and commercialization of a new idea is long, a journey of many considerations and constituencies.

But here is another answer that the threads we are finding in this issue reveal. Namely, technology adoption seems slow because we are still in the low-slope part of the hockey-stick-shaped curve. Gains multiply once they add to other gains, and transformation’s cumulative effects come on the other side of this threshold. Many people are applying AM to advance many aspects of power generation systems. What will happen when they all discover one another?

Related Content

ConocoPhillips Sees Oil and Gas Supply Chain Opportunity With Additive Manufacturing

Production of parts when needed and where needed can respond to the oil and gas sector’s multibillion-dollar challenge of holding parts in inventory. The supply chain benefit will justify additive even before the design freedoms are explored.

Read MoreAM Will Change Power Generation, But Needs To Prove Itself First

In gas turbines and in nuclear power, Oak Ridge National Laboratory is working with major manufacturers to validate metal 3D printing for conventional parts as a prelude to developing the unconventional ones.

Read MoreAdvancing Additive Manufacturing With a CATCH and Release Approach

Solutions for energy efficiency, sustainability, part repair and more are developing at Siemens’ Charlotte Advanced Technology Collaboration Hub (CATCH) in North Carolina.

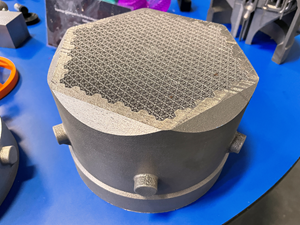

Read More3D Printed Heat Exchanger Illustrates Siemens' CATCH and Release Approach

Solutions for energy efficiency, sustainability, part repair and more are developing at Siemens’ Charlotte Advanced Technology Collaboration Hub (CATCH) in North Carolina.

Read MoreRead Next

Gas Turbine Swirlers: Co-Optimizing Despite the Complexity

Power generation and additive manufacturing researchers at Penn State University have joined forces to explore what impact the design of a swirler can have on gas turbine performance.

Read MoreAM Will Change Power Generation, But Needs To Prove Itself First

In gas turbines and in nuclear power, Oak Ridge National Laboratory is working with major manufacturers to validate metal 3D printing for conventional parts as a prelude to developing the unconventional ones.

Read MoreMicroturbine Relies on 3D Printed Housing to Preheat Fuel

The aluminum housing designed with nTopology and made on a Velo3D laser powder bed fusion system helps realize what its creators say will be the highest-power-density small turbine yet produced.

Read More