Honeywell: How Tooling Wins Acceptance of AM from Engineering, Manufacturing, Finance

Because of the power and importance of culture, tooling is the starting point for succeeding with AM.

Share

Read Next

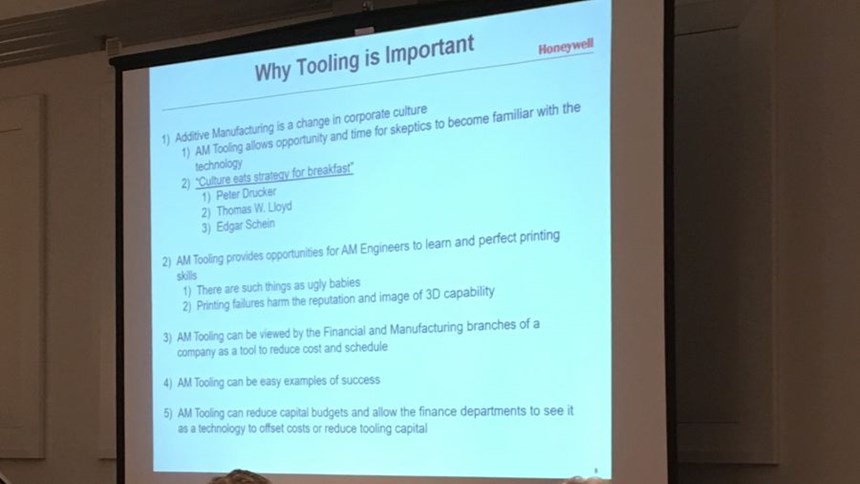

A photo is worth a thousand words? This photo featuring a simple presentation slide with about 100 words on it has a great deal to say about the importance of 3D-printed tooling. This shot was taken during a talk given by Donald Godfrey, engineering fellow with Honeywell, at the most recent AMUG Conference. As this slide says, “Culture eats strategy for breakfast.” Any top-down strategy to adopt additive manufacturing is likely to fail in the face of a culture that is not prepared to accept and embrace this technology. However, using AM to make tooling—that is, 3D printing internally used custom tools as a prelude to eventually 3D printing finished parts—can provide an effective means of beginning to win over the culture.

We devoted much of our May 2017 issue to the promise of AM tooling, and you can read more about tooling here.

Here is the text of the slide by Dr. Godfrey that appears in the image above:

Why Tooling is Important

1. Additive manufacturing is a change in corporate culture.

- AM tooling allows opportunity and time for skeptics to become familiar with the technology.

- "Culture eats strategy for breakfast." (Quote has been attributed to Peter Drucker, Thomas W. Lloyd and Edgar Schein.)

2. AM tooling provides opportunity for AM engineers to learn and perfect printing skills.

- There are such things as ugly babies.

- Printing failures harm the reputation and image of 3D capability.

3. AM tooling can be viewed by the financial and manufacturing branches of a company as a tool to reduce cost and schedule.

4. AM tooling can be easy examples of success.

5. AM tooling can reduce capital budgets and allow the finance departments to see it as a technology to offset costs and reduce tooling capital.

Related Content

-

How to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

-

3D Printing Molds With Metal Paste: The Mantle Process Explained (Video)

Metal paste is the starting point for a process using 3D printing, CNC shaping and sintering to deliver precise H13 or P20 steel tooling for plastics injection molding. Peter Zelinski talks through the steps of the process in this video filmed with Mantle equipment.

-

How 3D Printing Will Change Composites Manufacturing

A Q&A with the editor-in-chief of CompositesWorld explores tooling, continuous fiber, hybrid processes, and the opportunities for smaller and more intricate composite parts.